Khoom cov tsis muaj cov khoom lag luam tseem ceeb

| Tus cwj pwm | Tus nqi |

|---|---|

| Khoom | Polyvinyl chloride (PVC) |

| Kub tiv thaiv | - 40 ℃ Rau 80 ℃ |

| Xim Xaiv | Tau sib kho |

| Daim ntawv thov | Cov freezer gaskets, trims, Cheebtsam |

Cov Khoom Lag Luam Khoom Tshwj Xeeb

| Kev qhia tshwj xeeb | Me mem quav naim |

|---|---|

| Ceev | 1.4 g / cm³ |

| Kev nyuaj | 80 ntug dej d |

| Lub zog tensile | 45 n / mm² |

| Kev Cuam Tshuam | Ceeb toom cuam tshuam lub zog 15 KJ / M² |

Cov khoom lag luam tsim khoom

Nyob rau hauv cov ntawv sau npe hu ua npe hu ua Engine cov ntaub ntawv ', qhov kev nkag mus rau cov txheej txheem ntawm polymer los ntawm kev tuag raws kev tswj hwm kub thiab ntsuas. Tus txheej txheem no ua kom muaj txiaj ntsig zoo thiab muaj peev xwm rau cov qauv kev tsim, ntsib cov cuab yeej kev lag luam cov qauv kev lag luam. PVC LUB CEV ADMINISTIVE RAU EXCRITIVE Ntxiv kom ua rau nws cov ntawv thov OREYER thiab ua kom muaj tshuaj lom neeg corrosion thiab kev ua kom muaj txiaj ntsig rau lub freezer.

Khoom Daim Ntawv Thov

Raws li cov ntawv xov xwm 'polymer' polymer thiab thev naus laus zis ', PVC Extrusion Qhov chaw yog pivotal hauv kev lag luam khoom siv. Lawv siv hauv cov neeg khov suav suav nrog lub zog - cov kab ua kom ruaj khov, thiab cov khoom siv sab hauv uas tiv taus corrosion thiab tswj kev nyiam huv. Cov ntawv thov no underscore cov khoom siv rau versatility thiab qhov tseem ceeb hauv kev xa cov kev daws teeb meem hauv cov tshuab hluav taws xob txias thoob ntiaj teb.

Khoom tom qab - muag kev pabcuam

Peb muaj kev pom zoo tom qab kev muag khoom muag nrog rau kev teeb tsa kev teeb tsa, kev tiv thaiv kev pabcuam, thiab kev hloov chaw kom muaj kev txaus siab thiab cov khoom lag luam thiav.

Cov Tsheb Thauj Mus Los

Cov khoom lag luam tau ruaj ntseg ntim thiab ntim khoom ntawm cov koom tes logistics txhim kho, kom ua raws sijhawm thiab nyab xeeb rau cov chaw ua si thoob ntiaj teb.

Cov khoom lag luam zoo

- Ruaj thiab lub teeb

- Customizable rau ntau yam kev siv

- Eco - Cov kev xaiv zoo muaj

- Tus nqi - Siv tau zoo

- Qib Siab Thermal Kev Ua Haujlwm

Khoom Muag FAQ

- Dab tsi yog qhov ntsuas kub uas tau 80 extrusion qhov chaw tuaj yeem tiv taus?

Raws li cov neeg xa khoom, peb muab cov ntawv sau ntxiv rau lub freezer uas tuaj yeem tiv thaiv kev tiv thaiv kub los ntawm - 40 ℃ mus rau 80 ℃, kom muaj kev ua tau zoo raws li kev ua tau txawv txav.

- Puas yog cov chaw no customizable?

Yog lawm, cov neeg muab khoom tuaj yeem muab cov khoom siv luam rau PVC

- Yuav ua li cas rau PVC pab rau kev ua kom muaj zog hauv cov neeg khov?

Pvc lub cal thermal tsawg yuav pab tswj kom sov thiab siv hluav taws xob kom tsawg rau PVC Extrusion Part rau cov neeg ua haujlwm ua kom tau cov khoom siv txhim kho.

- Dab tsi ua rau pvc haum rau cov freezer gaskets?

Cov chaw muag khoom xaiv PVC rau nws qhov yooj, detability, thiab kev tawm tsam ya raws, ua rau nws zoo tagnrho rau cov tshuab cua uas tiv thaiv cov pa txias.

- Cov txiaj ntsig tseem ceeb ntawm kev siv PVC hauv freezers?

Tus neeg xa khoom kom pom tseeb rau PVC LUB CEV HEEV, Kev Ua Tau Zoo, thiab nws cov khoom nyiam rau kev tsim khoom dua tshiab hauv cov chaw ua haujlwm.

- Puas yog siv PVC muaj?

Yog, tus neeg muag khoom nce rov qab siv dua tshiab PVC Extrusion Part rau lub freezer, txhawb nqa ib puag ncig kev ruaj khov yam tsis muaj kev sib cuam tshuam zoo.

- Tau PVC Walland cuam tshuam?

PVC Extrusion Qhov chaw rau cov dej khov yog tsim los ua kev puas tsuaj - tiv taus thiab tswj kev tiv thaiv kev tsim nyog, kev txhim kho kev tsim nyog rau cov cuab yeej siv thiab cov sab hauv.

- Dab tsi yog cov kev siv ntawm PVC extrusion seem?

Suppliers provide pvc extrusion part for freezer used in door gaskets, trims, internal supports, and protective components, serving essential roles in appliance functionality.

- Yuav ua li cas cov neeg muag khoom kom ua tau zoo?

Nrog nruj nruj kom tswj tau tias txhua PVC extrusion ib feem rau lub freezer ua tau raws li kev lag luam qauv, siv cov txuj ci siab rau kev ua haujlwm ruaj khov thiab ua tau zoo.

- Dab tsi yog nce qib hauv plicchnements?

Cov chaw muag khoom tau txais cov tswv yim tshiab uas cia rau customized cov yeeb yam xws li kev cuam tshuam UV tsis kam lees rau PVC Extrusion Seem rau cov ntawv thov lub chaw kho mob.

Khoom Kub Khoom Kub

- Lub neej yav tom ntej ntawm PVC extrusion nyob rau hauv lub Freezer Raug

Lub Innovored Innovation hauv cov ntaub ntawv thiab cov txheej txheem yog khaws cov neeg xa khoom ntawm PVC Extrusion Part rau lub freezer ntawm qhov ua tau zoo thiab eco - alltub. Raws li kev siv khoom siv rau ib puag ncig ib puag ncig, cov neeg muab khoom siv BIO - Raws li cov txheej txheem ua rov qab los muab cov kev daws teeb meem ntau dua.

- Yuav ua li cas PVC extrusion hloov kho cov tshuab nqus paszer

Tus neeg muab khoom siv muaj qhov sib luag hauv kev txhim kho lub freezer los ntawm kev tsim PVC extrusion part rau lub freezer uas ua kom muaj zog rwb thaiv tsev. Kev nrhav nyob rau hauv cov khoom kev tshawb fawb yog ua kom muaj cov teeb meem kub muaj txiaj ntsig zoo dua, tseem ceeb ntawm lub luag haujlwm ntawm PVC hauv kev sib ntsib lub zog txheem.

- Customization: Cov Ntsiab Kom Tau Txais PVC Extrusion Tus Neeg Muag Khoom

Kev muab PVC rho tawm rau lub freezer nrog cov kev xaiv customization tso cai tsim cov kev daws teeb meem uas muaj kev zoo nkauj thiab ua haujlwm. Qhov no muaj peev xwm ua kom tau ua kom zoo li ntawd PVC tseem muaj ntau yam kev xaiv hauv kev ua lag luam hloov zuj zus.

- Qhov cuam tshuam ib puag ncig ntawm PVC hauv kev tsim khoom

Cov khoom siv PVC, tshwj xeeb tshaj yog nyob rau hauv extrusion seem rau cov dej khov, yog nce txuas ntxiv rov ua dua tshiab thiab eco cov ntaub ntawv phooj ywg. Cov khoom siv tau cog lus los txo cov hneev taw carbon thiab pab txhawb kev lag luam ntau los ntawm kev siv cov khoom tshiab tshiab.

- PVC EXTRUSION: Cov chaw hais txog cov tshuab luam hluav taws xob thoob ntiaj teb

Raws li thoob ntiaj teb xav tau cov kev daws teeb meem hauv tub yees, lwm tus neeg Qhov tseem ceeb yog muab tso rau kev saib xyuas zoo thaum ntsib cov kev xav tau ntawm kev lag luam thoob ntiaj teb, pom zoo PVC qhov kev yoog tau.

- Cov txheej txheem thev naus laus zis hauv PVC Exitusion Txheej Txheem

Cov chaw muag khoom txuas ntxiv cov tshuab ua thev naus laus zis los txhim kho qhov precision thiab kev ua tau zoo ntawm PVC extrusion part rau lub freezer ntau lawm. Kev sib txuam tom ntej no - Kev tsim kev hlub tuag thiab kev siv tshuab ua qauv txhim kho cov zis zoo thiab txo cov sijhawm txhuas.

- Vim li cas thiaj xaiv pvc dua lwm cov ntaub ntawv?

PVC lub cim tshwj xeeb, xws li cov tshuaj tsis kam thiab thermal conductivity, ua rau nws tsis tseem ceeb rau cov neeg khov. Cov chaw muag khoom nyiam PVC Extrusion Feem rau lub freezer tshaj lwm txoj hauv kev, kom ua tau zoo txhim kho thiab kev txuag nqi rau cov tuam ntxhab.

- Lub luag haujlwm ntawm cov chaw muag khoom hauv PVC Innovation

Cov neeg muag khoom sawv ntawm lub helm ntawm PVC Extrusion Perfenion Of Admaries, tsav tsheb kev lag luam kev txhim kho kom ua tau zoo thiab cov hom phiaj ib puag ncig.

- Cov kev sib tw hauv PVC extrusion rau freezers

Thaum PVC tseem yog cov khoom siv uas tseem ceeb, tus neeg xa khoom muaj kev sib tw xws li tswj cov kev mob ntau yam thiab kev tsim kho ib puag ncig ib puag ncig. Kev cog lus cia kom kov yeej cov ntaub ntawv txuas ntxiv qhov tseeb.

- Qhia cov lag luam tshiab nrog PVC Extrusion Qhov Chaw

Tus neeg muag khoom ntawm PVC Extrusion Qhov chaw rau lub tub yees ua kom cov kev siv hluav taws xob uas daws teeb meem hauv lub zog

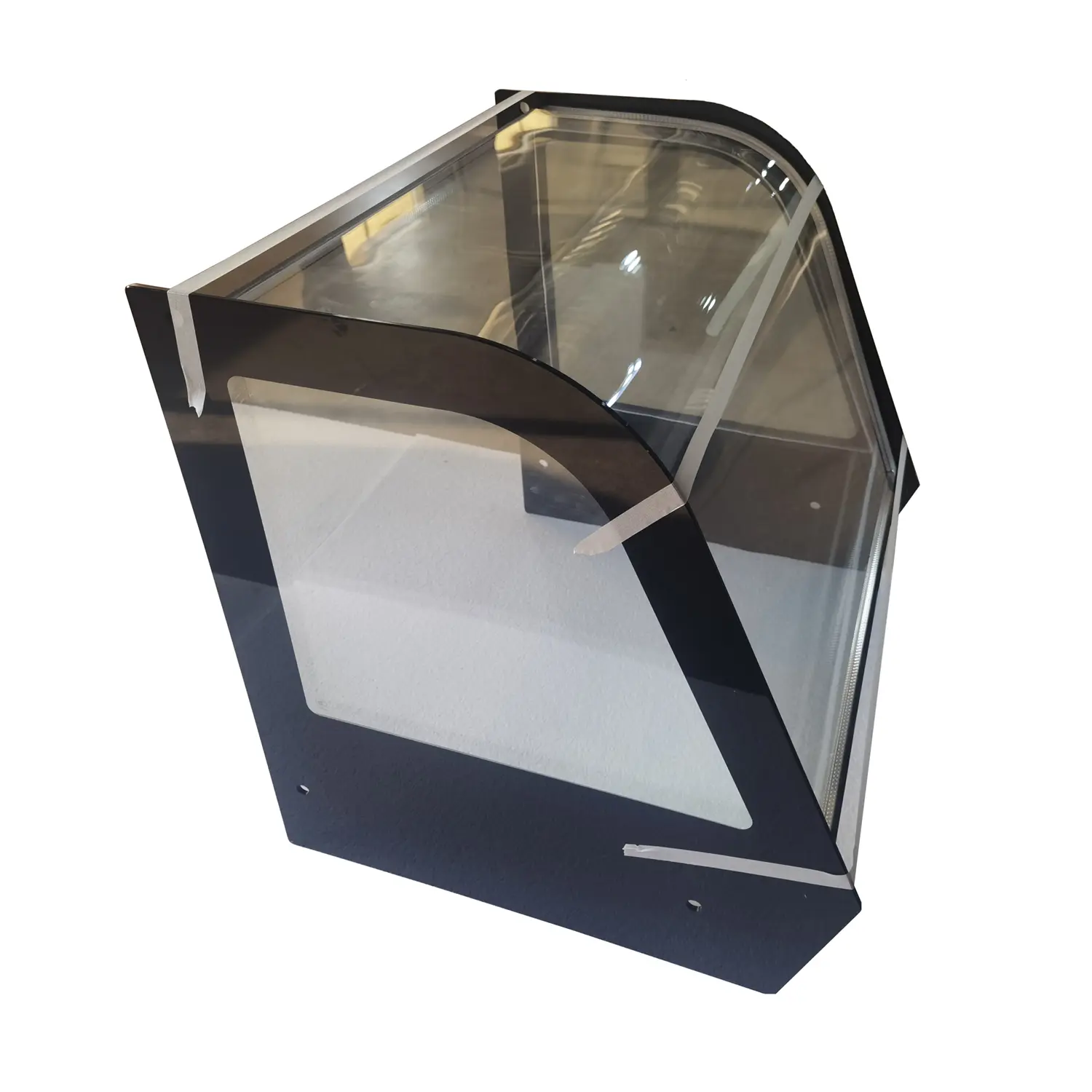

Duab piav qhia

Tsis muaj cov lus piav qhia rau cov khoom no