Product Details

| Specification | Details |

|---|---|

| Material | 3D Digital Toughened Glass |

| Thickness | 3mm-19mm, Customized |

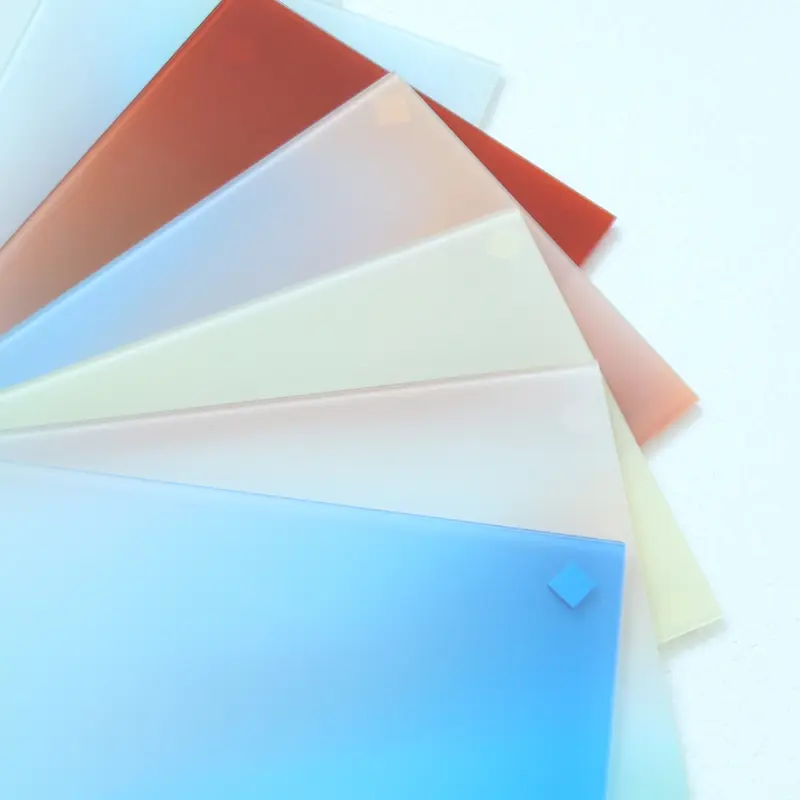

| Color | Red, White, Green, Blue, Gray, Bronze, Customized |

| Logo | Customized |

| Shape | Flat, Curved, Customized |

| Application | Furniture, Facades, Curtain Wall, Skylight, etc. |

| Use Scenario | Home, Kitchen, Shower Enclosure, Office, etc. |

| Package | EPE foam Seaworthy wooden case (Plywood Carton) |

| Service | OEM, ODM, etc. |

| Warranty | 1 Year |

| Brand | YB/Customized |

Common Product Specifications

| Feature | Description |

|---|---|

| Fire-fused Glass | Permanently adhered to glass surface |

| Environmental Resistance | Aging resistant and stable, does not fade |

| Maintenance | Easy to clean |

| Design Capabilities | No limitation on colors and images |

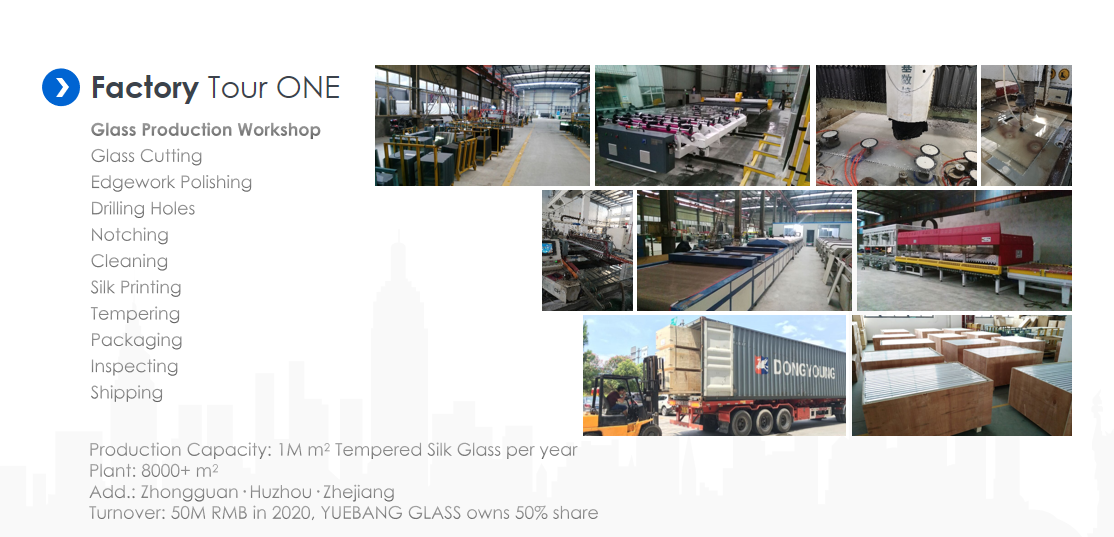

Product Manufacturing Process

The manufacturing process of 3D digital toughened glass involves several stages that enhance its durability and design potential. Initially, glass is subjected to intense heat and rapid cooling to achieve a toughened state, increasing its resistance to impact and thermal stress. This process is complemented by digital printing technology, which allows precise application of complex designs directly onto the glass surface. The digital printing utilizes ceramic inks that are fired into the glass, ensuring that the design is both vibrant and long-lasting. This combination of processes not only enhances the aesthetic appeal but also maintains structural integrity, making it ideal for diverse applications ranging from architecture to electronics. Research indicates that these processes result in a material that balances form and function, offering significant advantages over traditional glass in terms of safety and creative potential.

Product Application Scenarios

3D digital toughened glass is widely used in various sectors due to its robustness and aesthetic versatility. In architecture and construction, it serves as a key material for facades, curtain walls, and interior partitions, offering both decorative appeal and functional benefits like UV protection and thermal insulation. The automotive industry benefits from its durability and customizability in applications like windshields and sunroofs. In electronics, it is utilized for screens and interfaces, providing protective and aesthetic enhancements. Additionally, interior designers often use this glass for decorative elements such as wall panels and furniture tops, capitalizing on its ability to integrate complex designs. Studies highlight its transformative effect on modern design practices, emphasizing its role in achieving energy efficiency and visual innovation.

Product After-sales Service

Our factory offers comprehensive after-sales service to ensure customer satisfaction with our 3D digital toughened glass products. We provide a one-year warranty covering manufacturing defects and offer support for installation and maintenance queries. Our team is available for consultations to address any specific issues, offering solutions and replacements if necessary. We are committed to ensuring the longevity and performance of our products, reflecting our dedication to quality and customer care.

Product Transportation

We ensure secure transportation of our 3D digital toughened glass products with careful packaging using EPE foam and seaworthy wooden cases. Our logistics team coordinates efficient shipping, whether by land, air, or sea, to guarantee timely delivery while maintaining product integrity. We track shipments closely and offer updates to customers, ensuring peace of mind throughout the transportation process.

Product Advantages

- Durable and impact-resistant, suitable for high-traffic areas.

- Customizable designs with vibrant, long-lasting colors.

- Environmentally friendly manufacturing process reduces waste.

- Easy maintenance and cleaning requirements.

- Enhances building energy efficiency with thermal insulation properties.

Product FAQ

- Q: What is the main advantage of 3D digital toughened glass?

A: The main advantage is its combination of durability and design flexibility. Our factory produces this glass to withstand high impact and thermal stress, making it suitable for various applications, while the digital printing allows for intricate designs.

- Q: Can I customize the design and color of the glass?

A: Yes, customization is one of the key features of our 3D digital toughened glass. Our factory can incorporate any design or color you require, ensuring a perfect fit for your project needs.

- Q: What safety features does this glass offer?

A: This glass is toughened to provide enhanced safety, breaking into small, blunt pieces if shattered, reducing the risk of injury. Our factory ensures each piece meets strict safety standards.

- Q: How do I maintain the 3D digital toughened glass?

A: Maintenance is simple. Regular cleaning with non-abrasive products will keep the glass looking its best. The factory ensures the glass is designed for easy upkeep.

- Q: What industries use this type of glass?

A: It is used across various industries, including architecture, automotive, electronics, and interior design. The factory's customization capabilities allow it to meet diverse requirements.

- Q: How is the glass packaged for shipping?

A: Our factory uses EPE foam and sturdy wooden cases for packaging, ensuring the glass is well-protected during transit to prevent damage.

- Q: Can it be used in exterior applications?

A: Yes, its durability and resistance to weather conditions make it suitable for exterior applications like facades and curtain walls. Our factory's production standards ensure excellent performance in all settings.

- Q: Is installation support available?

A: Our factory offers after-sales support, including installation guidance, to ensure your 3D digital toughened glass is properly set up and utilized.

- Q: What makes this glass environmentally friendly?

A: The digital printing process is resource-efficient, reducing waste compared to traditional methods. Our factory prioritizes sustainable practices in manufacturing.

- Q: What is the warranty policy?

A: We offer a one-year warranty covering manufacturing defects, ensuring peace of mind with your purchase from our factory.

Product Hot Topics

Aesthetic Versatility in 3D Digital Toughened Glass: This glass is transforming modern architecture with its aesthetic versatility, allowing architects to push creative boundaries with intricate, custom designs. Our factory ensures top quality in every piece, offering a wide range of colors and patterns to suit diverse projects.

The Future of Building Facades: As sustainability becomes a central focus, our 3D digital toughened glass is at the forefront, providing energy efficiency and stunning visual appeal. Our factory's innovative production methods enhance the glass's functionality and aesthetic impact.

Safety and Durability in Public Spaces: In high-traffic areas, safety is crucial. Our factory's 3D digital toughened glass is designed to provide superior durability, reducing the risk of injury while maintaining an elegant appearance.

Custom Glass Solutions for Interior Design: Interior designers benefit from the customizability of our 3D digital toughened glass, using it for bespoke elements like wall panels and furniture. Our factory supports unique, tailored designs to fit any aesthetic vision.

Advancements in Digital Printing Technology: The digital printing capabilities at our factory represent a significant advancement, allowing for precise, vibrant designs that traditional methods couldn't achieve. This opens new possibilities for creative expression in glass design.

Environmentally Responsible Manufacturing: Our factory's commitment to sustainable practices ensures that our 3D digital toughened glass is both environmentally responsible and aesthetically superior, contributing to greener building practices.

Applications in the Automotive Industry: Our 3D digital toughened glass is increasingly used in automotive design, offering durability and aesthetic enhancement for vehicle interiors and exteriors. Our factory's expertise allows for innovative automotive solutions.

Enhancing Electronics with Robust Glass: In electronics, our glass enhances durability and aesthetics for screens and panels. Our factory integrates cutting-edge technology to meet the demands of electronic manufacturers.

Cost-effective Customization Options: Our factory provides cost-effective customization options for 3D digital toughened glass, enabling projects to achieve unique aesthetics without compromising on budget or quality.

Trends in Glass Architecture: As trends in architecture evolve, our factory's 3D digital toughened glass remains at the forefront, offering innovative solutions that blend design with functionality, making it a staple in modern construction.

Image Description