Product Details

| Feature | Description |

|---|---|

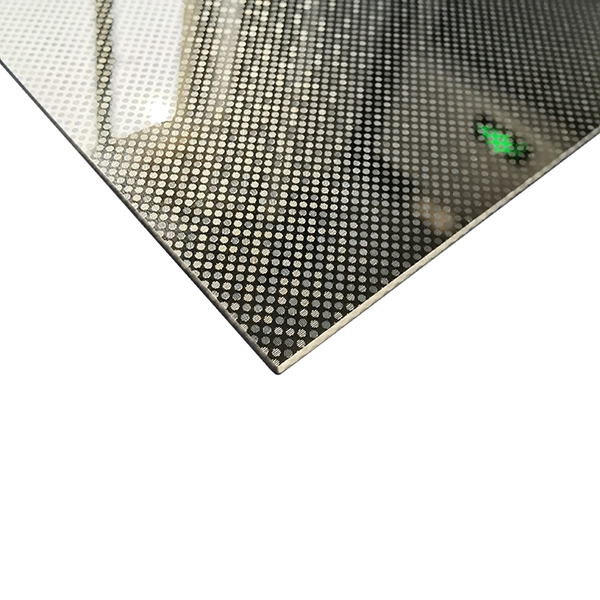

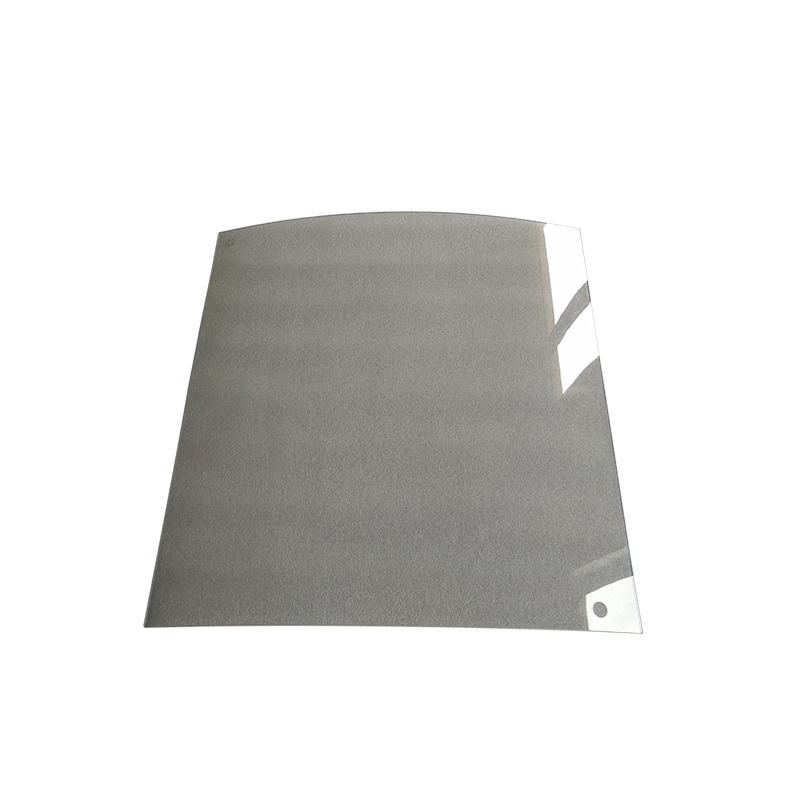

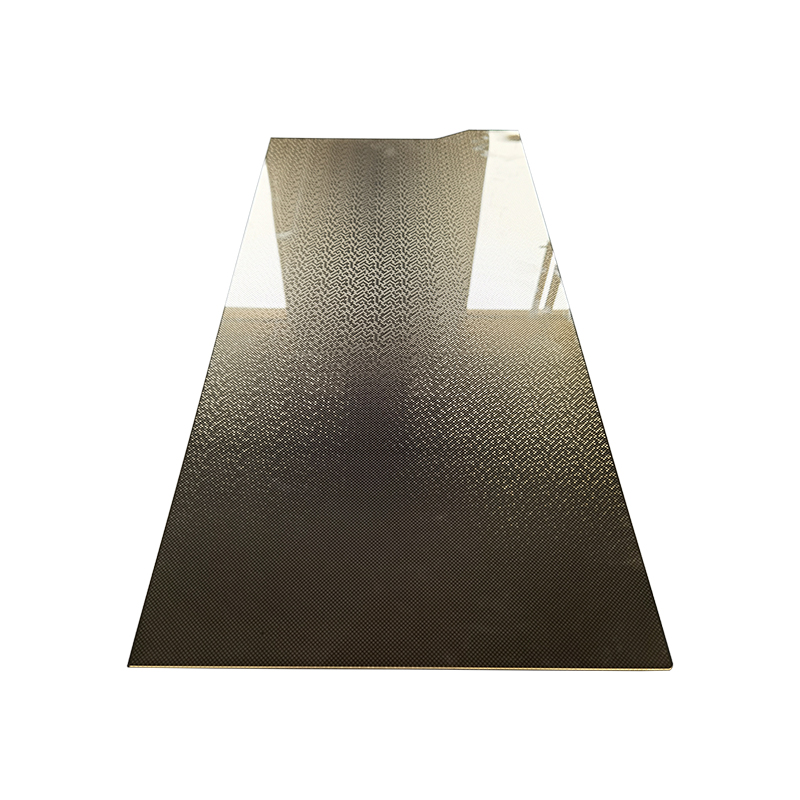

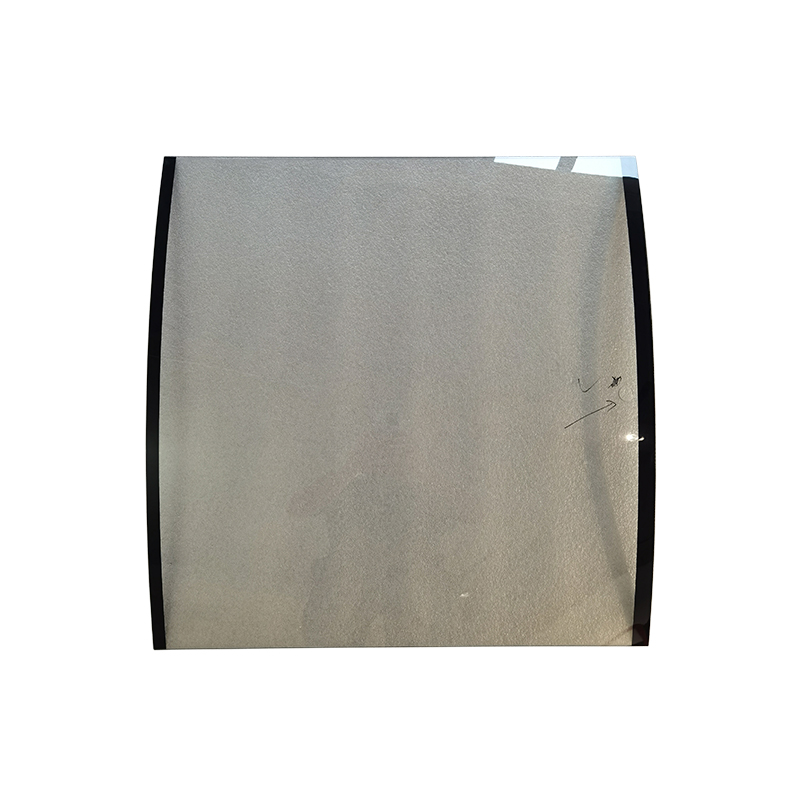

| Product Name | Curved Glass for Refrigerator |

| Glass Type | Tempered Glass, Silk Screen Printing Glass |

| Thickness | 3mm-19mm |

| Shape | Curved |

| Size | Max 3000mm x 12000mm, Min 100mm x 300mm, Customized |

| Color | Clear, Ultra Clear, Blue, Green, Grey, Bronze, Customized |

| Edge | Fine Polished Edge |

| Structure | Hollow, Solid |

| Technique | Clear Glass, Painted Glass, Coated Glass |

| Application | Buildings, Refrigerators, Doors and Windows, Display Equipment |

| Package | EPE foam Seaworthy wooden case (Plywood Carton) |

| Service | OEM, ODM |

| Warranty | 1 Year |

Common Product Specifications

| Specification | Details |

|---|---|

| Material | Grade A High-Quality Annealed Glass |

| Manufacturing | Glass Bending and Tempering Process |

Product Manufacturing Process

The manufacturing process of China curved glass for refrigerator involves several steps. Initially, flat glass sheets are heated in a controlled environment until they become pliable. This process is known as glass bending. Once the desired curvature is achieved, the glass is cooled gradually to enhance its strength through tempering. This tempering process makes the glass resistant to thermal stress and impact, improving its safety features. Additionally, coating and silk screening techniques can be applied to add decorative elements or enhance functionality. These processes ensure that the curved glass meets specific design and performance criteria, making it suitable for various applications from commercial displays to high-end residential solutions.

Product Application Scenarios

China curved glass for refrigerator is widely utilized across various scenarios, driven by its functional and aesthetic benefits. In commercial settings such as supermarkets and cafes, curved glass is integral in display refrigerators, offering unobstructed views and attracting customer attention. In the hospitality industry, wine coolers employ curved glass to create sophisticated displays that also maintain optimal wine storage conditions. For residential applications, high-end kitchens often feature custom refrigeration solutions incorporating curved glass to match contemporary design aesthetics. The versatility and functionality of curved glass make it a preferred choice for architects and designers aiming to merge visual appeal with practical benefits.

Product After-Sales Service

We commit to ensuring the satisfaction of our customers with our China curved glass for refrigerator. Our after-sales service provides free spare parts and a comprehensive warranty of one year. Our service team is readily available to assist with any issues or queries, ensuring smooth operations and customer satisfaction.

Product Transportation

Our China curved glass for refrigerator is securely packaged using EPE foam and seaworthy wooden cases to ensure it reaches its destination safely. We work with reliable shipping partners to offer timely and efficient delivery worldwide.

Product Advantages

- Outstanding performance in resisting thermal stress and wind-load

- Stable chemical performance and outstanding transparency

- Can withstand a wide range of temperature changes

- High strength, Anti-collision, Explosion-proof

- Scratch resistant, Acid and Alkali resistant

Product FAQ

- What makes China curved glass safer than regular glass? China curved glass is tempered, making it more resistant to impact. If broken, it shatters into small, blunt pieces, reducing the risk of injury compared to ordinary glass.

- Is curved glass energy efficient? Yes, the design of China curved glass for refrigerator helps to minimize air leakage, improving insulation and energy efficiency, which can lead to lower operational costs.

- Can the glass color be customized? Absolutely, our China curved glass is available in various colors including clear, ultra-clear, blue, green, and more, ensuring compatibility with any design scheme.

- What is the maximum size of the curved glass? We offer customized sizes up to 3000mm x 12000mm, suitable for various applications from small displays to large refrigerator doors.

- How is the glass packed for shipping? We use EPE foam and seaworthy wooden cases for packing, ensuring that the glass is well-protected during transportation.

- What applications are suitable for China curved glass? Curved glass is versatile, perfect for commercial displays, wine coolers, and custom residential refrigerators, enhancing both function and aesthetic appeal.

- How does tempered glass enhance safety? Tempered glass undergoes a toughening process that makes it resistant to breaking. If it does shatter, it breaks into small pieces that are less likely to cause injury.

- Does the curvature affect visibility? Curved glass offers wider viewing angles, improving visibility of displayed items, which is particularly beneficial in retail environments to attract customers.

- Is the glass resistant to scratches? Yes, the tempered glass surface is highly resistant to scratches as well as acid and alkaline substances, ensuring durability and longevity.

- What is the warranty period for the glass? We offer a one-year warranty on our China curved glass for refrigerator, supported by our dedicated after-sales service team.

Product Hot Topics

- The Rise of China in Curved Glass Manufacturing for Refrigeration

China has become a global leader in the production of curved glass for refrigeration applications, thanks to its advanced technology and cost-effective production methods. The country's expertise in both manufacturing and exporting this high-quality glass makes it a preferred supplier for businesses worldwide seeking to enhance their refrigeration units with modern design and efficient functionality. China's competitive edge lies in its ability to integrate cutting-edge glass bending and tempering techniques, resulting in products that meet international quality standards. As demand continues to grow, China's role in this niche market is expected to expand further, solidifying its status as a key player in curved glass manufacturing.

- Benefits of Curved Glass in Modern Refrigerator Design

Curved glass is redefining refrigerator design by offering a unique combination of aesthetics and performance. The sleek, seamless appearance of curved glass doors not only enhances the visual appeal of appliances but also improves functionality. In commercial settings, refrigerators with curved glass doors draw more consumer attention, increasing sales potential. Additionally, the improved insulation properties of curved glass contribute to energy savings, making these refrigerators more environmentally friendly. As sustainability becomes a priority, manufacturers are likely to invest more in developing curved glass technology, ensuring it meets evolving market needs.

- Challenges in Producing High-Quality Curved Glass for Refrigerators

Producing high-quality curved glass poses several challenges, including achieving uniform curvature without compromising the glass's structural integrity. Precise temperature control during the bending and tempering process is crucial to prevent defects. Furthermore, manufacturers must ensure that the glass is free from imperfections and can withstand significant temperature fluctuations. Despite these challenges, advancements in technology have enabled China to excel in the production of superior curved glass, meeting the demands of both domestic and international markets. Ongoing research and development efforts continue to address these manufacturing challenges, paving the way for even higher quality standards in the future.

- Environmental Impact of Using Curved Glass in Refrigeration

The use of curved glass in refrigeration impacts the environment positively by enhancing energy efficiency. By reducing the points where air can escape, curved glass helps maintain consistent internal temperatures, decreasing the energy consumption of refrigerators. Furthermore, the manufacturing process for tempered curved glass has evolved to minimize waste and emissions, reflecting a shift towards more sustainable production practices. As global emphasis on reducing carbon footprints grows, the adoption of energy-efficient technologies like curved glass in appliances is expected to rise, contributing to environmental conservation efforts.

- Innovation Trends in Curved Glass Technology for Refrigerators

Recent innovations in curved glass technology focus on enhancing both aesthetic and functional elements. Developments such as anti-reflective coatings improve visibility while reducing glare, and advanced insulating materials bolster energy efficiency. Manufacturers are also exploring interactive glass technologies, integrating smart features like touch controls directly onto the glass surface. These innovations reflect a broader trend towards creating multifunctional and stylish appliances that cater to the tech-savvy consumer. As research continues, it is likely that we will see further breakthroughs that will redefine the role of curved glass in refrigeration.

- Comparing Flat vs Curved Glass in Refrigerator Design

Curved glass offers a modern alternative to traditional flat glass in refrigerator design. While both have their own advantages, curved glass provides a wider viewing angle and a more seamless aesthetic, appealing to consumers seeking contemporary designs. It also offers slight improvements in energy efficiency due to better thermal seals. However, flat glass is typically less expensive and may suffice for budget-conscious applications. Ultimately, the choice between flat and curved glass depends on the specific needs of the application, including design preferences and performance requirements.

- The Future of Curved Glass in the Appliance Market

Curved glass is poised to become an integral component in the appliance market. As consumers increasingly value design alongside functionality, the demand for aesthetically pleasing appliances like those featuring curved glass will rise. Future trends suggest that curved glass will incorporate more smart technology, enhancing user interaction and convenience. This evolution will likely spur growth in complementary sectors, such as smart home integration and energy-efficient solutions. The future holds promising potential for curved glass, driven by innovation and consumer demand for sophisticated, efficient appliances.

- Consumer Preferences for China-Made Curved Glass Refrigerators

China-made curved glass refrigerators are gaining favor among consumers worldwide due to their competitive pricing and high-quality standards. Chinese manufacturers have successfully combined advanced glass manufacturing techniques with cost efficiencies, delivering products that meet a wide array of consumer preferences. These include an emphasis on modern design, energy conservation, and durability. As China continues to innovate in this sector, its products are expected to become even more attractive to global markets, appealing to consumers who prioritize both value and performance in their purchasing decisions.

- The Role of Curved Glass in Enhancing Retail Display Refrigeration

Retail display refrigeration has been revolutionized by the introduction of curved glass, which enhances product visibility and appeals to consumer aesthetics. The seamless design of curved glass allows for better light distribution and less reflection, creating an inviting display that highlights the quality of the products. Retailers benefit from this innovation by attracting more customer attention and potentially boosting sales. As retail environments continue to evolve, the strategic use of curved glass will play an essential role in optimizing product presentation and enhancing the overall shopping experience.

- Market Demand for Curved Glass in Commercial Refrigeration

The demand for curved glass in commercial refrigeration is on the rise as businesses seek to improve both the functionality and aesthetics of their display units. Curved glass not only enhances the visual appeal of these units but also supports energy-efficient operations, aligning with current trends in sustainability. Industries such as food retail and hospitality are particularly invested in adopting curved glass solutions to attract and retain customers through improved product presentation. The market landscape indicates steady growth for curved glass as its benefits continue to align with the needs of commercial refrigeration applications worldwide.

Image Description