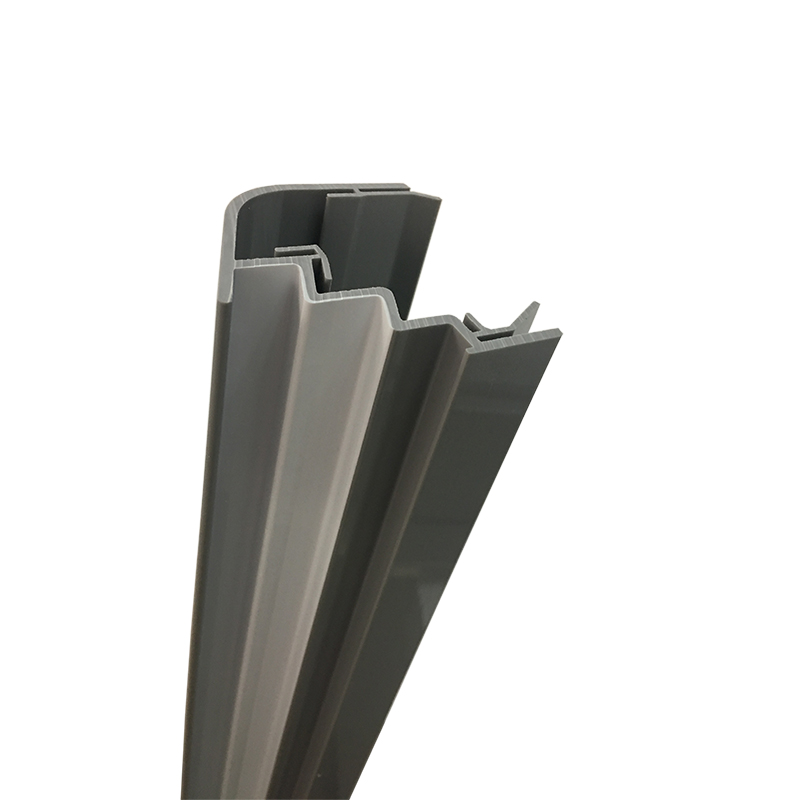

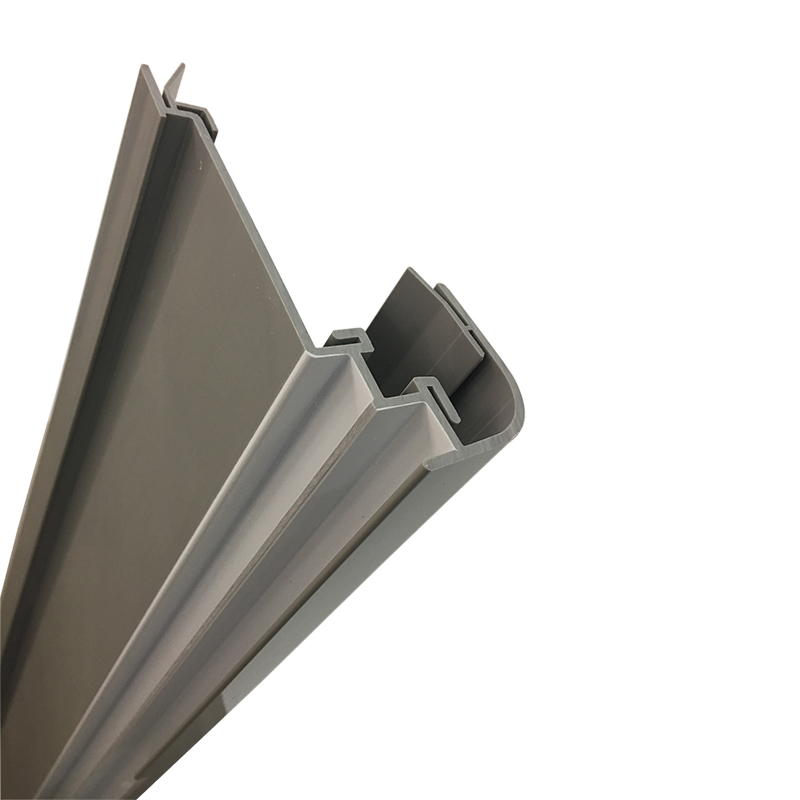

Product Details

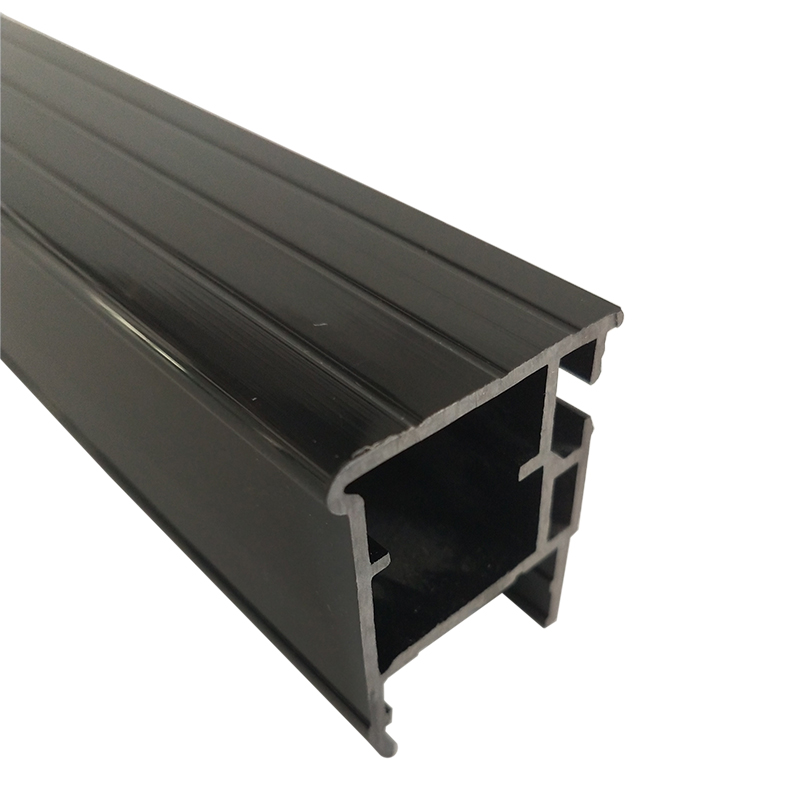

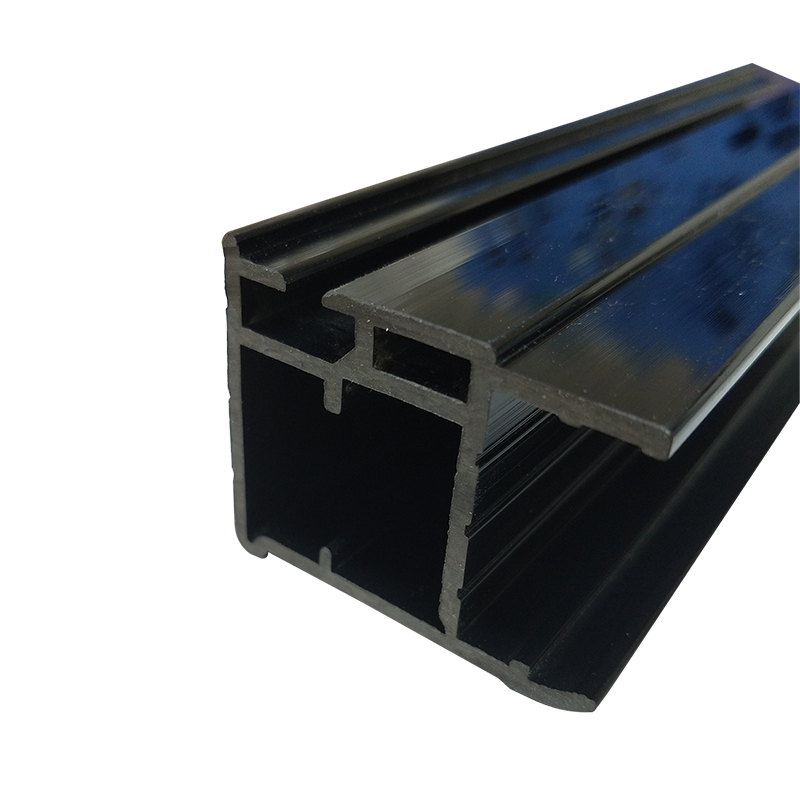

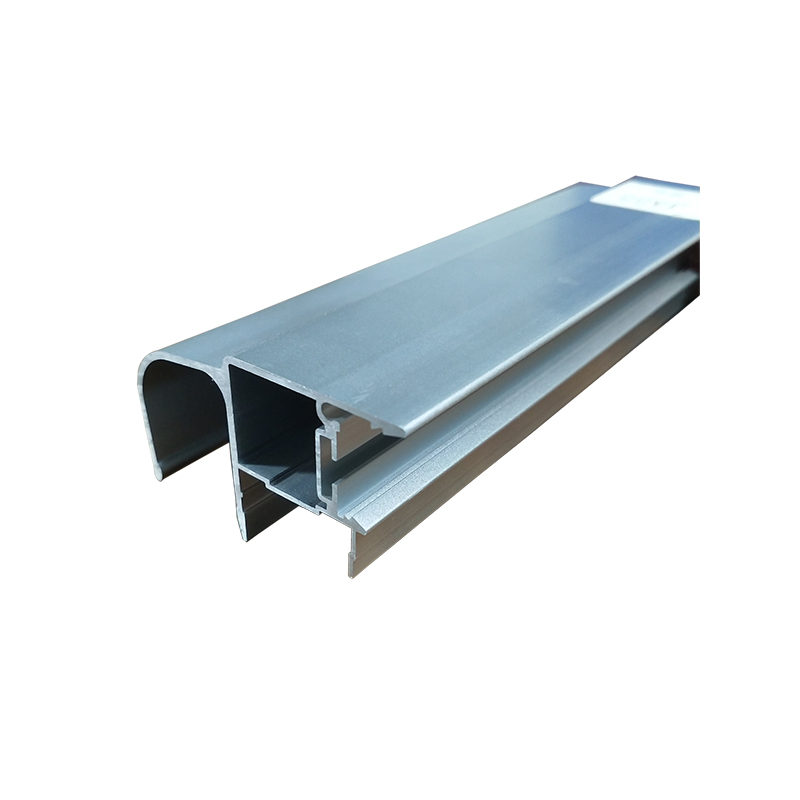

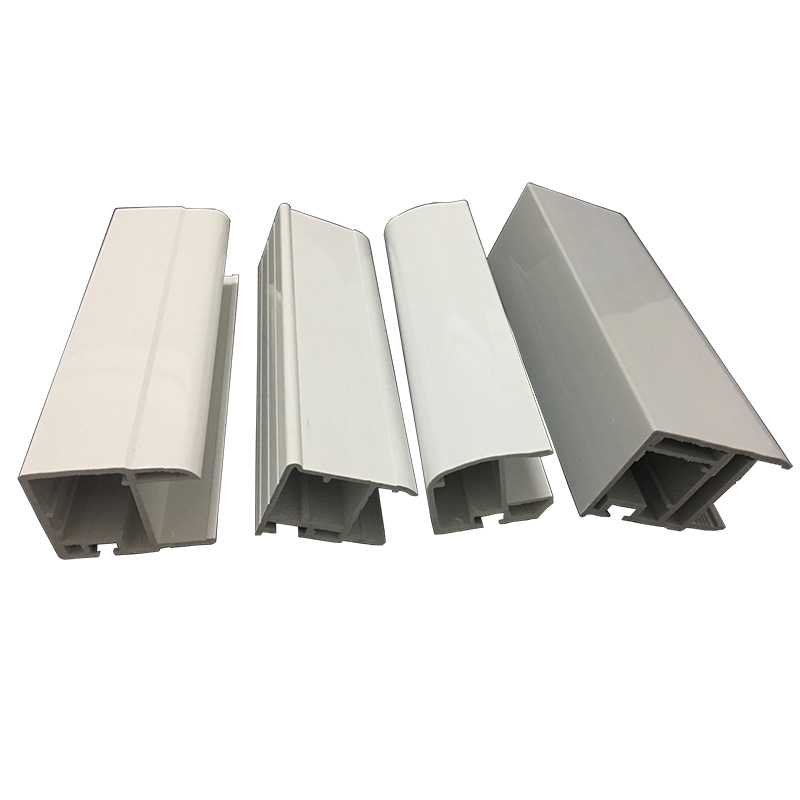

| Product Name | Custom PVC Frame for Freezer |

|---|---|

| Material | PVC, ABS, PE |

| Type | Plastic Profiles |

| Thickness | 1.8-2.5MM or as Customer Required |

| Shape | Customized Requirement |

| Color | Silver, White, Brown, Black, Blue, Green, etc. |

| Usage | Construction, Building Profile, Refrigerator Door, Window, etc. |

| Application | Hotel, House, Apartment, Office Building, School, Supermarket, etc. |

| Package | EPE foam Seaworthy wooden case (Plywood Carton) |

| Service | OEM, ODM, etc. |

| After-sales Service | Free Spare Parts |

| Warranty | 1 Year |

| Brand | YB |

Product Specifications

| Durability | High strength corrosion resistance and anti-aging performance |

|---|---|

| Space Efficiency | Space saving, easy operating, easy to install and clean |

| Stability | Strong processing stability and good fluidity |

| Temperature Resistance | High and low temperature resistance |

| Environmental Impact | Material is environmentally friendly |

Product Manufacturing Process

The manufacturing of custom PVC frames for freezers involves precise and advanced extrusion techniques. PVC, a highly durable and versatile plastic material, is subjected to a series of processes that ensure its stability and resilience. The extrusion process begins with the melting of raw PVC pellets, which are then forced through a die to form the desired profile shape. This is followed by cooling and cutting the profiles to the required dimensions. Quality checks are carried out to ensure uniformity and strength. According to authoritative papers, this process not only enhances the durability of PVC frames but also optimizes their thermal and moisture resistance, making them exceptionally suited for freezer applications.

Product Application Scenarios

Custom PVC frames for freezers are extensively used across commercial and domestic settings. In commercial environments, these frames are pivotal in creating robust shelving solutions that sustain large quantities of products at consistently low temperatures. For home use, PVC frames assist in organizing freezer contents efficiently, providing necessary support to storage racks and partitions. In industrial contexts, their ability to support significant loads while maintaining structural integrity is invaluable. As highlighted in authoritative studies, the insulating properties and lightweight nature of PVC make it an ideal choice for various freezer applications, contributing to energy efficiency and longevity of use.

Product After-Sales Service

We offer comprehensive after-sales service for our custom PVC frame for freezer, ensuring customer satisfaction and optimal product performance. Our services include a 1-year warranty and free spare parts, available to address any issues promptly. Our dedicated customer support team is available to assist with installation guidance, troubleshooting, and technical queries. Regular follow-ups and feedback channels ensure continuous improvement of our products and services.

Product Transportation

Our custom PVC frames for freezers are packaged using EPE foam and seaworthy wooden cases to ensure safe and secure transit. We partner with leading logistics providers to guarantee timely delivery to both domestic and international locations. Customers are provided with tracking information to monitor their shipment’s progress from dispatch to arrival.

Product Advantages

- Longevity: Featuring moisture and temperature resistance, ensuring extended lifespan.

- Lightweight: Easier handling and reduced overall system weight.

- Non-Conductive: Enhances safety by eliminating electrical shock risk.

- Versatile Design: Customizable to various shapes and sizes for specific needs.

- Sustainability: Many parts are recyclable, supporting environmental efforts.

Product FAQ

What is the temperature range PVC frames can withstand?

Custom PVC frames for freezers are designed to operate efficiently within a range of -40℃ to 80℃. However, they may become brittle if exposed to extreme temperatures beyond these limits.

Are the PVC frames environmentally friendly?

Yes, the PVC frames used in our freezers are crafted from environmentally friendly materials and are recyclable, aligning with sustainability goals.

How is the durability of PVC frames compared to other materials?

PVC frames are highly durable and resistant to moisture, wear, and environmental stresses, outperforming wood and competing effectively with metal in certain applications.

Can I customize the color and size of the PVC frames?

Yes, we offer customization options for color and size to meet customer specifications, ensuring the frames fit seamlessly into your freezer setup.

How easy is it to install PVC frames?

Installation is straightforward due to the lightweight nature of PVC frames, reducing handling difficulties and facilitating quick setup.

What maintenance do PVC frames require?

Maintenance is minimal. The frames are easy to clean and don't require painting or sealing, making them cost-effective over time.

Are PVC frames suitable for all types of freezers?

Custom PVC frames are versatile and can be designed to support a variety of freezer types, including commercial, domestic, and industrial units.

What chemical resistance do PVC frames offer?

PVC frames are resistant to many chemicals, but exposure to certain solvents and oils should be avoided. Consulting specific compatibility data is advisable.

How do PVC frames contribute to energy efficiency?

Thanks to their thermal insulation properties, PVC frames reduce the energy required to maintain consistent internal temperatures, contributing to overall energy savings.

What is the warranty period for PVC frames?

We provide a 1-year warranty on our custom PVC frames for freezers, which covers manufacturing defects and offers peace of mind to our customers.

Product Hot Topics

How Custom PVC Frames Enhance Freezer Efficiency

Understanding the impact of materials on freezer efficiency is crucial for both manufacturers and consumers. Custom PVC frames have proven to be a game-changer in this context. They not only provide robust support and structural integrity but also contribute significantly to energy savings. This is achieved through their excellent thermal insulation properties, which help maintain consistent internal temperatures and reduce the workload on refrigeration systems. Consequently, businesses and homeowners alike can enjoy lower energy bills and extend the lifespan of their refrigeration units. Moreover, the customization aspect allows users to tailor the frames to their specific needs, ensuring optimal performance and storage solutions.

The Versatility of Custom PVC Frames in Commercial Settings

For businesses that rely on commercial freezers, the versatility of custom PVC frames cannot be overstated. These frames are customizable in size and color, allowing them to fit seamlessly into various freezer designs and meet specific business requirements. Whether used to support large quantities of produce or organize high-turnover inventory, custom PVC frames provide the necessary structure and stability. Their resistance to moisture and temperature variations ensures they remain effective under demanding conditions, making them an indispensable component of commercial refrigeration setups. Companies can thereby enhance their operational efficiency while minimizing maintenance costs and maximizing space utilization.

Image Description