Product Main Parameters

| Feature | Specification |

|---|---|

| Glass Type | Double or Triple Layer Tempered Low-E |

| Frame Material | Curved/Flat Aluminum Alloy |

| Standard Sizes | 23''-30'' W x 67''-75'' H |

| Color | Silver, Black, Customizable |

| Warranty | 12 months |

Common Product Specifications

| Style | Commercial Walk In Cooler |

|---|---|

| Glass Layer | 2-3 Layers |

| Accessories | Handles, LED Light, Self-Closing Hinges |

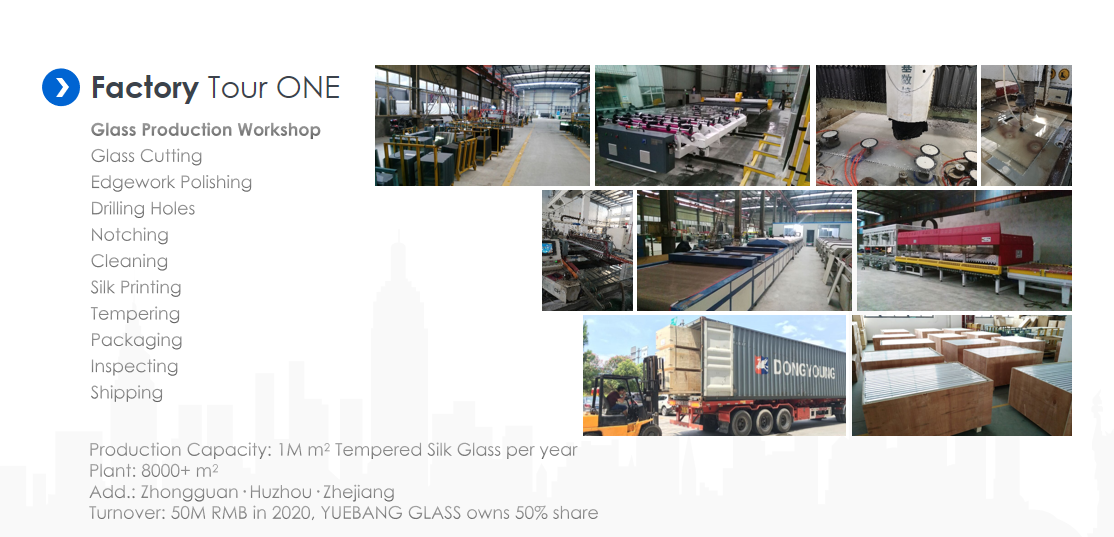

Product Manufacturing Process

The manufacturing of custom shelves for cold rooms involves several precise steps to ensure durability and efficiency. Initially, the glass is cut and polished, then drilled, notched, and thoroughly cleaned. Silk printing may be applied before the glass is tempered for strength. Hollow glass is assembled, while the PVC extrusion and frames are simultaneously prepared. These components are then skillfully assembled and packed for shipment. Studies assert that the meticulous combination of high-quality materials and precision manufacturing results in products that withstand cold room conditions, offering reliable and lasting performance.

Product Application Scenarios

Custom shelves for cold rooms are vital across various industries, including food storage, pharmaceuticals, and biotechnology. These shelves provide efficient organization and storage solutions, maintaining product integrity under temperature-controlled environments. Studies emphasize that the adaptability and durability of well-designed cold room shelving enhance operational efficiency and compliance with health standards. As companies expand their cold storage capabilities, investing in tailored shelving solutions remains a strategic priority for maximizing space and ensuring safety.

Product After-Sales Service

Free spare parts and a one-year warranty offer customers peace of mind and support. Our dedicated service team is ready to assist with any inquiries or issues, ensuring customer satisfaction with our custom solutions for cold room shelving.

Product Transportation

Products are securely packaged with EPE foam and seaworthy wooden cases to prevent damage during transit, ensuring they arrive safely and in pristine condition.

Product Advantages

- Energy-efficient with heating and LED options.

- Customizable in design, size, and color to suit specific needs.

- Durable construction for long-term use.

- Compliant with international safety standards.

Product FAQ

- Q: What materials are used in the custom shelves for cold room?

A: Our custom shelves for cold rooms use high-quality tempered Low-E glass and aluminum alloy frames, ensuring durability and resistance to low temperatures.

- Q: Can the shelves be customized to different sizes?

A: Yes, we offer a variety of standard sizes and can customize shelves to fit specific requirements, providing flexibility for different storage needs.

- Q: How does the anti-condensation feature work?

A: The Low-E glass with argon gas filling and heating options prevents condensation by stabilizing internal glass temperatures, thus maintaining clear visibility.

- Q: What is the lead time for a custom order?

A: Lead times vary; in-stock items typically ship within 7 days, while custom orders are completed in 20-35 days after deposit confirmation.

- Q: Is the product energy-efficient?

A: Yes, our shelves come with energy-efficient LED lighting and optional heating features to optimize energy use while maintaining cold room conditions.

- Q: What warranty is included?

A: We provide a one-year warranty, covering any manufacturing defects to ensure customer satisfaction with our quality products.

- Q: Are these shelves suitable for food storage?

A: Absolutely, our shelves meet industry standards, making them ideal for food storage with hygienic, corrosion-resistant designs.

- Q: What kind of maintenance is required?

A: Routine cleaning and periodic inspections are advised to keep the shelves in optimal condition, ensuring long-term durability and effectiveness.

- Q: Can I add my logo to the product?

A: Yes, we offer branding options for our customers, allowing you to include your logo on the custom shelves.

- Q: How are the shelves packaged for shipping?

A: We pack the shelves in EPE foam and secure wooden cases to protect them during transit, ensuring they reach you safely.

Product Hot Topics

- Custom Shelves for Cold Room Efficiency

Integrating custom shelves for cold room environments optimizes storage solutions by allowing businesses to effectively manage their space and inventory. Utilization of these shelves contributes to cost savings and operational efficiency, making them a crucial part of any cold storage setup.

- Regulatory Compliance with Custom Shelves

Staying compliant with industry regulations is essential, and custom shelves for cold rooms help businesses achieve this. Meeting standards set by organizations like the FDA ensures the safety and quality of stored goods, which is especially critical in sectors like food and pharmaceuticals.

- Improving Cold Room Usability with Custom Shelves

Custom shelving provides flexibility in storage arrangements, enabling easy access and organization. This is vital in fast-paced environments where quick access to temperature-sensitive goods is essential, reducing the risk of spoilage and maintaining quality.

- The Role of Custom Shelves in Energy Efficiency

Custom shelves designed for cold rooms contribute to energy efficiency by allowing for better air circulation and temperature management. This not only reduces energy costs but also helps in maintaining consistent storage conditions.

- Technological Advancements in Custom Shelves

Innovations in materials and design technology have significantly improved the functionality of custom shelves for cold rooms. Features like anti-condensation coatings and energy-efficient lighting are now integral, enhancing the performance and utility of these systems.

- Sustainability Considerations for Custom Shelves

Choosing sustainable materials for custom shelves in cold rooms has become increasingly important. Incorporating eco-friendly materials not only supports environmental goals but also attracts customers who value sustainability in their business practices.

- Adapting to Market Trends with Custom Shelves

As market demands evolve, the adaptability of custom shelves for cold rooms becomes a competitive advantage. Businesses can respond to changing needs with reconfigurable designs that support different product types and storage requirements.

- Cost-Effective Custom Shelving Solutions

Investing in custom shelves for cold rooms may require initial expense, but the long-term savings on energy and space utilization prove cost-effective. This investment enhances the overall efficiency and sustainability of cold storage operations.

- Enhancing Cold Room Aesthetics with Custom Shelves

Custom shelves offer not just functionality but also contribute to the aesthetic appeal of cold rooms. With options for colors and finishes, they can align with brand identity and create a visually appealing storage environment.

- Future Trends in Custom Cold Room Shelving

The future of custom shelves for cold rooms looks promising with the continuous development of smart technologies. Features like integrated sensors for real-time monitoring could further revolutionize cold storage management.

Image Description