Product Main Parameters

| Parameter | Specification |

|---|---|

| Glass Type | 4mm Tempered Low-E Glass |

| Frame Material | ABS and Aluminum |

| Width | 660mm (Fixed) |

| Length | Customizable |

| Temperature Range | -30℃ to 10℃ |

Common Product Specifications

| Feature | Description |

|---|---|

| Anti-Fog | Yes |

| UV Resistance | Yes |

| Heating Mechanism | Electrical |

| Energy Efficiency | High |

Product Manufacturing Process

The process of manufacturing factory electrical heated glass doors for freezers involves a meticulous sequence of operations that guarantees high quality and performance. The production begins with selecting high-grade raw materials, such as tempered Low-E glass, known for its low emissivity and energy-saving properties. The glass undergoes precision cutting and edge polishing to achieve exact dimensions and smooth edges. Drilling and notching are done to accommodate fixtures, followed by a thorough cleaning to remove debris. A silk printing process is applied for branding and aesthetic appeal. The glass is then tempered at high temperatures to enhance its strength and thermal performance.

Product Application Scenarios

Factory electrical heated glass doors for freezers are pivotal in retail and food service industries where visual appeal and energy efficiency are crucial. In supermarkets and grocery stores, these doors provide clear displays of frozen goods, enticing customers while maintaining low operating costs. Convenience stores benefit from the reduced energy consumption and enhanced product visibility leading to better sales turnovers. In the food service sector, such products ensure ingredients are preserved optimally while remaining accessible for culinary purposes. The features of these doors align with the growing emphasis on sustainability, making them ideal for modern retail and service environments.

Product After-Sales Service

Our after-sales service ensures customer satisfaction by offering comprehensive support post-purchase. This includes troubleshooting assistance, repair services, and replacement parts for the factory electrical heated glass doors for freezers. Our dedicated team is available to answer queries and provide guidance on maintenance to prolong the life and efficiency of the product.

Product Transportation

Transportation of our factory electrical heated glass doors for freezers is handled with utmost care to prevent damage. We use specially designed packaging materials that cushion the glass and frames, ensuring they arrive intact. Our logistics partners are experienced in handling fragile items, ensuring timely delivery globally.

Product Advantages

- Enhanced Visibility: Clear view through fog-free glass.

- Energy Efficiency: Reduced energy costs.

- Durability: Long-lasting components.

- Temperature Regulation: Maintains product quality.

- User Convenience: Easy product access.

Product FAQ

- What makes the factory electrical heated glass door for freezer unique?

The unique feature lies in its electrically heated mechanism that prevents fogging, ensuring clear visibility of products while enhancing energy efficiency. - How does the heating mechanism operate?

The heating mechanism employs a conductive coating between glass layers, which heats up when powered to prevent condensation without excessive energy consumption. - Can the length of the glass doors be customized?

Yes, while the width is fixed at 660mm, the length can be customized to fit specific freezer models. - What materials are used in the frame construction?

The frame is constructed using ABS injection with aluminum alloy, providing strength and thermal insulation. - How does the product contribute to energy savings?

By minimizing the need to frequently open freezer doors, it reduces energy loss and maintains a stable internal temperature, enhancing efficiency. - Is the glass UV resistant?

Yes, our glass doors incorporate UV resistant materials to prevent damage and enhance durability. - What temperature range can the doors withstand?

The doors are designed to function effectively between -30℃ and 10℃, making them suitable for various freezer environments. - What after-sales services are offered?

We provide troubleshooting, repair, and part replacement services to ensure the longevity and performance of our products. - Is the product compliant with safety standards?

Yes, all components meet ROHS and REACH standards, ensuring safety and environmental compatibility. - What is the lifespan of the heating element?

The heating element is designed for long-term operation with minimal wear and tear, ensuring durability and reliability.

Product Hot Topics

- Discussing the Impact of Factory Electrical Heated Glass Doors on Retail Energy Costs

The adoption of factory electrical heated glass doors for freezers has been a game-changer in retail energy management. By minimizing frequent door openings and the resultant loss of cold air, these doors significantly cut down on energy consumption. Their advanced heating technology ensures just the right amount of heat to prevent condensation without excessive energy use, thus aligning perfectly with the goals of modern, eco-conscious businesses. Retailers have reported noticeable savings in their utility bills and applaud the role of these glass doors in their sustainability efforts. - The Role of Factory Electrical Heated Glass Doors in Enhancing Product Visibility

Factory electrical heated glass doors for freezers are celebrated for their ability to maintain a clear and condensation-free surface. This feature is particularly advantageous in retail settings where product visibility directly influences consumer buying decisions. Customers can easily locate their desired items without opening the doors, which not only improves shopping experience but also aids in maintaining stable internal temperatures within freezers. This innovation effectively merges aesthetics with functionality, driving sales while supporting energy efficiency.

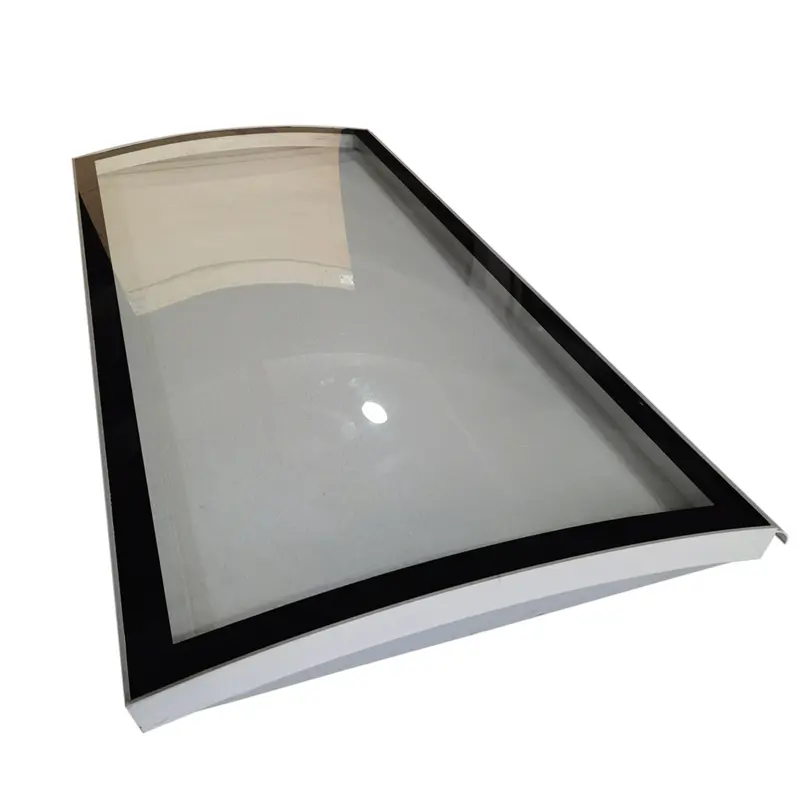

Image Description