Product Main Parameters

| Feature | Specification |

|---|---|

| Glass Type | Tempered Low-E Glass |

| Thickness | 4mm |

| Max Size | 2440mm x 3660mm |

| Min Size | 350mm x 180mm |

| Color | Clear, Ultra Clear, Gray, Green, Blue |

| Temperature Range | -30℃ to 10℃ |

Common Product Specifications

| Application | Freezer/Cooler/Refrigerator |

|---|---|

| Package | EPE foam Seaworthy plywood carton |

| Service | OEM, ODM |

| After-sales Service | Free Spare Parts |

| Warranty | 1 Year |

Product Manufacturing Process

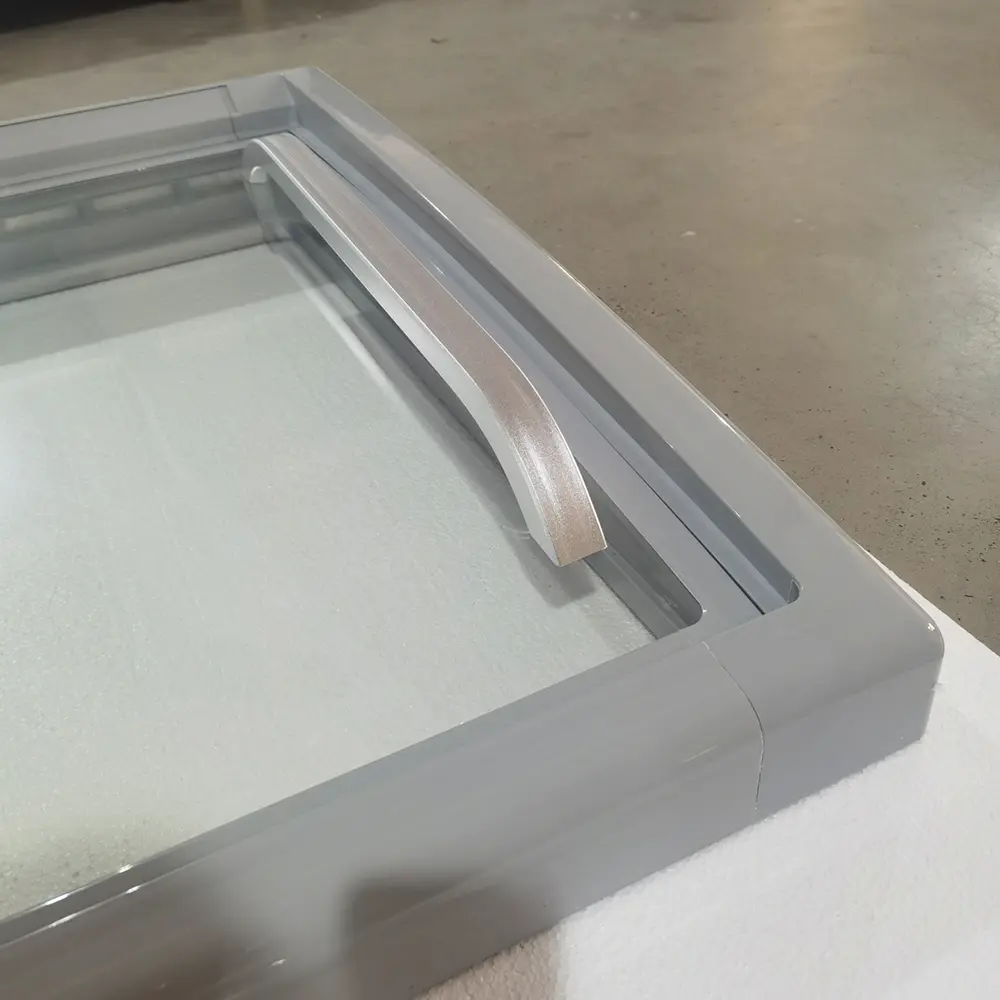

In the manufacturing process of sliding glass doors for freezers, ensuring both quality and functionality is paramount. Generally, the process begins with the precise cutting of the glass to meet specific design requirements. Following this, the edges are polished to ensure smoothness and safety. Any necessary drilling and notching are done prior to a thorough cleaning phase. Next, silk printing often takes place where applicable. The glass is then tempered, enhancing its strength and resistance to temperature variations. For insulated products, additional layers or coatings are applied to increase thermal efficiency. The components are then assembled, including any frame or extrusion work needed. Each glass door is packed carefully using EPE foam and seaworthy cartons to ensure they reach their destination undamaged. This comprehensive production process is supported by quality control measures, including tests for thermal shock resistance and condensation prevention. These processes are aligned with practices discussed in numerous industry papers, which emphasize the importance of energy efficiency and durability in cold-climate glass door manufacturing.

Product Application Scenarios

The application of frozen sliding glass doors is critical in environments requiring stringent temperature control, such as supermarkets, beverage stores, and cold storage facilities. These doors are designed to maintain optimal internal temperatures, preventing energy loss and ensuring that the products within remain fresh. Studies have shown that implementing such advanced glass door solutions can significantly reduce operational costs related to energy consumption. Applications extend beyond basic refrigeration needs; they are central to industries where maintaining specific climate conditions is necessary for product integrity. This capability is underscored in several industry reviews, suggesting that investing in high-quality sliding glass doors yields long-term savings and sustainability benefits.

Product After-sales Service

- Free spare parts provided within the warranty period.

- Comprehensive guidance available for installation and maintenance.

- Customer support to address any product concerns promptly.

Product Transportation

Our products are transported using robust packaging solutions designed to withstand long-distance travel. The use of EPE foam and seaworthy wooden cartons ensures that each glass door remains secure and undamaged during transit.

Product Advantages

- Exceptional energy efficiency and temperature control capabilities.

- Durability with high resistance to environmental stressors.

- Versatile design options to fit various commercial needs.

Product FAQ

- Q: Are you a manufacturer?

- A: Yes, we are a Factory and Frozen Sliding Glass Door Manufacturer with over 20 years of industry experience.

- Q: What is your minimum order quantity?

- A: Our MOQ varies by design. Contact us with your specifications for details.

- Q: How can I customize my order?

- A: We offer extensive customizations on size, color, and specifications to meet your needs.

- Q: What payment methods do you accept?

- A: We accept T/T, L/C, Western Union among other methods.

- Q: How long is the warranty?

- A: Our products come with a 1-year warranty.

- Q: When can I expect delivery?

- A: Delivery times depend on stock availability and order specifications. Typical lead time is 20-35 days.

- Q: Is there after-sales support?

- A: Yes, we provide comprehensive after-sales support to address any concerns.

Product Hot Topics

- Comment: As a top-tier Frozen Sliding Glass Door Manufacturer, Yuebang Factory consistently delivers on quality and innovation. Through their advanced production process, they offer sliding door solutions that are both durable and energy-efficient, critical for maintaining temperature-sensitive environments.

- Comment: In cold climates, choosing the right Frozen Sliding Glass Door Manufacturer is essential. Yuebang Factory stands out for its commitment to product excellence and customer satisfaction, offering solutions that meet the rigorous demands of cold storage facilities.

Image Description