| Feature | Specification |

|---|---|

| Glass | 4mm Tempered Low-E Glass |

| Frame | ABS Injection Width, Aluminum Alloy Length |

| Size | Width: 660mm, Length: Customized |

| Shape | Curved |

| Color | Black, Customizable |

| Temperature | -25℃ to 10℃ |

| Application | Chest Freezer, Island Freezer, Ice Cream Freezer |

| Warranty | 1 Year |

| Parameter | Value |

|---|---|

| Anti-fog | Yes |

| Anti-condensation | Yes |

| Visual Light Transmittance | High |

| Solar Energy Transmittance | High |

| Far Infrared Radiation Reflectance | High |

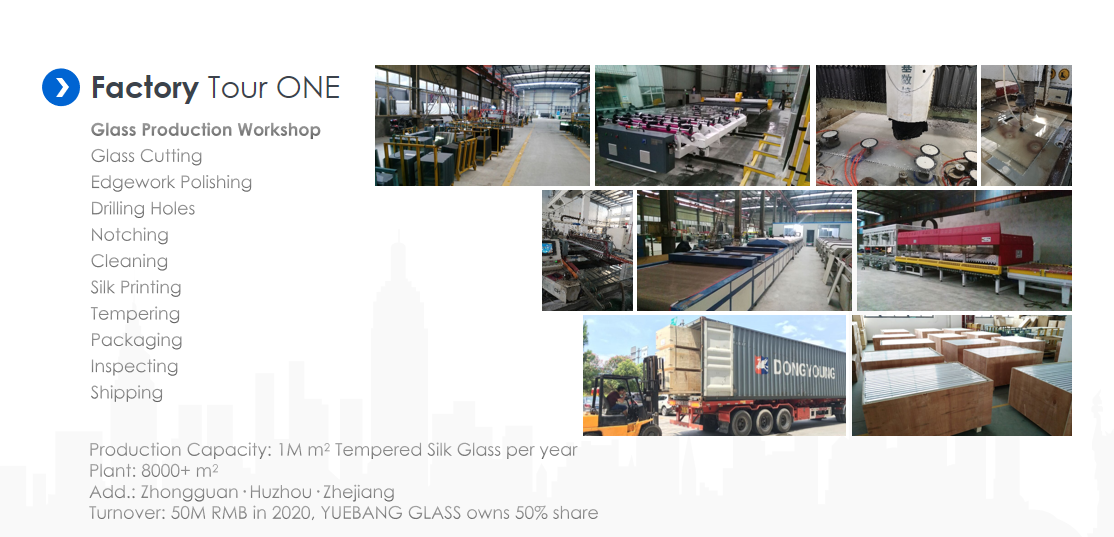

The manufacturing process for factory glass doors for display refrigerators involves a series of carefully planned steps to ensure quality and durability. The process begins with glass cutting to the appropriate size, followed by edge polishing to ensure smooth edges and safety. Holes are drilled for hinges and fittings, and notching allows for secure placement of hardware. The glass is then thoroughly cleaned to remove impurities that could affect the final product. Silk printing may be applied for designs or logos, followed by tempering to enhance strength and thermal resistance. Mounting the hollow glass into a robust frame is the last step before packaging and shipment. This comprehensive process ensures that each unit produced by our factory meets the highest standards of quality and functionality. According to industry standards, careful attention to each step not only prevents defects but also enhances the energy efficiency and lifespan of the glass door, as noted in industry journals focused on manufacturing best practices.

Factory glass doors for display refrigerators are integral to various commercial and retail settings, such as supermarkets, convenience stores, and cafes. These doors allow for clear visibility of products, enhancing customer experience and increasing sales. The primary function of these doors is to maintain optimal temperature settings while offering aesthetic appeal and reducing energy consumption. They help in preserving the quality of perishable goods by minimizing the frequency of door openings, thus maintaining a stable internal temperature. According to several studies, visibility and easy access provided by glass doors lead to increased impulse purchases and customer satisfaction. These factors make them indispensable tools for businesses aiming to showcase products while ensuring energy efficiency and reduced operational costs.

- Product After-sales Service: Yuebang Factory offers a comprehensive after-sales service including free spare parts and a one-year warranty on glass door display refrigerators.

- Product Transportation: Factory ensures safe transportation of glass doors using EPE foam and seaworthy wooden cases for maximum protection against damage during transit.

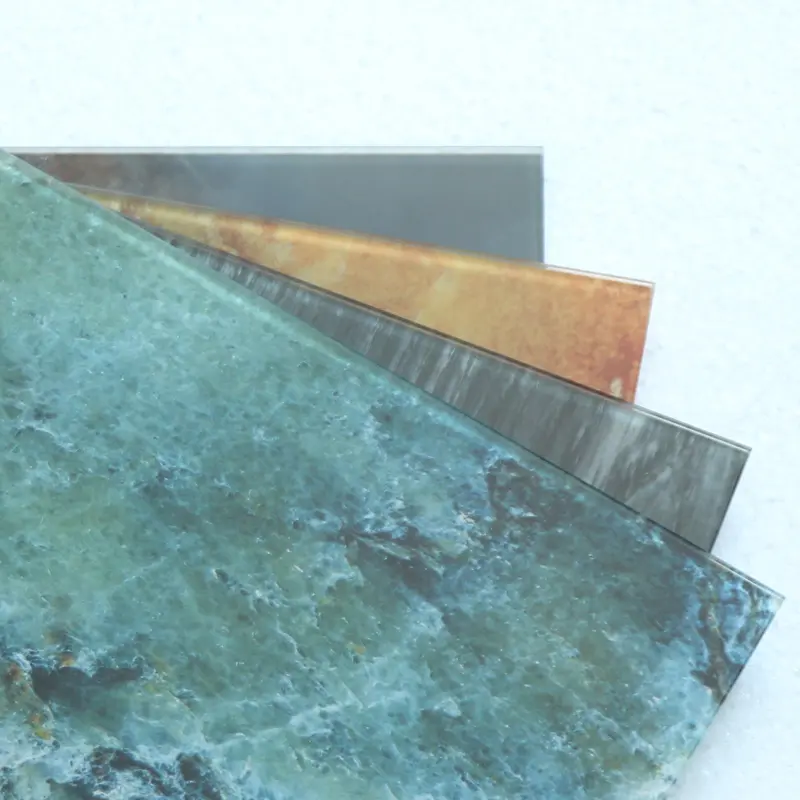

- Product Advantages: The factory-produced glass door for display refrigerators boasts features like anti-fog, high light transmittance, and exceptional temperature control, ensuring the perfect blend of aesthetics and functionality.

- FAQ:

1. How does the factory ensure the quality of the glass doors?

The factory has a specialized quality inspection laboratory that conducts a series of tests, including thermal shock and condensation tests, to ensure durability and optimal performance of glass doors used in display refrigerators.

2. Can customers request custom sizes for glass doors?

Yes, the factory offers customization options for glass door sizes to fit unique display refrigerator specifications, ensuring precise integration and improved aesthetic appeal.

3. What makes the factory's glass doors energy-efficient?

The factory utilizes Low-E glass, which has high solar energy transmittance and low emissivity, significantly reducing heat transfer and improving the energy efficiency of display refrigerators.

4. Is there a warranty on the glass doors?

Yes, the factory provides a one-year warranty on all glass doors for display refrigerators, ensuring peace of mind for customers and support for any potential product issues.

5. How does the factory handle bulk orders?

The factory has a production capacity of over 1,000,000m2 of tempered glass per year, allowing it to efficiently manage and fulfill bulk orders for glass doors.

6. What is included in the after-sales service?

The factory offers an after-sales service that includes technical support, provision of free spare parts, and responsive customer service to address any concerns related to glass door products.

7. Are the glass doors easy to install?

Yes, the factory designs glass doors with ease of installation in mind, providing detailed instructions and support to ensure smooth integration into any display refrigerator unit.

8. Do the glass doors have anti-fog properties?

Yes, the factory uses advanced anti-fog coatings on glass doors to maintain clear visibility and prevent condensation, enhancing the display experience.

9. What is the production time for custom glass doors?

The typical lead time for custom orders is 20-35 days, depending on the complexity and specifications of the glass doors requested by the customer.

10. Can the glass doors support branding or logos?

The factory offers silk printing and digital print options for glass doors, allowing customers to include branding elements or logos directly on the door surface.

- Product Hot Topics:

1. The Role of Factory-Produced Glass Door in Retail Settings

Factory-produced glass doors for display refrigerators play a crucial role in retail settings by providing energy-efficient solutions that enhance product visibility and accessibility. The use of high-quality tempered Low-E glass ensures durability and optimal temperature control, making these doors ideal for high-traffic areas in supermarkets and convenience stores. They help retailers minimize energy consumption while maintaining an attractive product display, which can lead to increased sales and customer satisfaction. The factory's dedication to quality and innovation in the manufacturing process further ensures that these glass doors meet the evolving needs of the retail industry.

2. Energy Efficiency in Factory-Produced Glass Door Display Refrigerators

Energy efficiency is a key consideration in the design and production of factory glass doors for display refrigerators. With the integration of Low-E glass and other energy-saving features, these doors help businesses reduce operational costs while maintaining the desired temperature range for perishable goods. The factory's commitment to incorporating cutting-edge technology into its products not only supports energy conservation efforts but also aligns with the growing demand for sustainable practices in commercial operations. This focus on efficiency makes factory glass doors an essential component of modern retail and food service environments.

3. Customization Capabilities of Factory Glass Doors for Display Refrigerators

The ability to customize factory glass doors for display refrigerators offers businesses the flexibility to meet specific design and functionality requirements. Whether it's adjusting the size, shape, or incorporating branding elements, the factory's customizable options ensure that the final product aligns with the customer's vision and operational needs. This adaptability is particularly beneficial for businesses looking to differentiate themselves in a competitive market by enhancing their product displays with unique and visually appealing refrigerator doors.

4. Advances in Factory Glass Door Technology and Its Impact on Retail

Recent advancements in factory glass door technology are revolutionizing the retail landscape by offering improved energy efficiency and enhanced product visibility. Innovations such as anti-fog coatings and heated glass technology reduce maintenance needs and improve customer experience by ensuring clear visibility at all times. These technological developments, combined with the factory's expertise in manufacturing, enable retailers to provide a better shopping experience while optimizing energy use and reducing environmental impact.

5. The Importance of Quality Control in Factory Glass Door Production

Quality control is paramount in the production of factory glass doors for display refrigerators, as it directly impacts the reliability and performance of the final product. The factory employs a rigorous quality inspection process that includes thermal shock tests, condensation resistance assessments, and other critical evaluations to ensure each glass door meets the highest industry standards. This commitment to quality helps businesses trust in the durability and efficiency of the products, leading to long-term benefits and cost savings.

6. Factory Glass Doors Enhance Product Display and Customer Experience

Factory glass doors are designed to enhance product display in retail environments by offering clear visibility and attractive presentation of items. This not only draws customer attention and interest but also promotes impulse purchases and increases overall sales. The factory's use of high-transmittance Low-E glass ensures that products are well-lit and easily accessible, creating a positive shopping experience that can contribute to customer loyalty and repeat business.

7. The Role of Factory Glass Doors in Reducing Food Waste

Factory glass doors for display refrigerators play a significant role in reducing food waste by maintaining consistent temperature control and minimizing energy loss. By ensuring that perishable goods are stored in optimal conditions, these doors help extend the shelf life of products and prevent spoilage. The factory's focus on quality and innovation further supports the goal of reducing food waste, making their glass doors an essential tool for environmentally-conscious retailers and food service providers.

8. How Factory Glass Doors Support Sustainability Initiatives

Factory glass doors for display refrigerators support sustainability initiatives by incorporating energy-efficient materials and technologies that reduce environmental impact. The use of Low-E glass and advanced insulation techniques helps lower energy consumption and carbon emissions, aligning with the growing demand for sustainable practices in commercial operations. By choosing factory-produced glass doors, businesses can demonstrate their commitment to sustainability while benefiting from reduced operational costs and improved product performance.

9. Market Trends Influencing Factory Glass Door Design

Market trends are continually influencing the design and production of factory glass doors for display refrigerators. With an increasing emphasis on energy efficiency and sustainability, manufacturers are exploring new materials and technologies to meet these demands. The factory's dedication to innovation ensures that their glass doors remain at the forefront of these trends, providing customers with cutting-edge solutions that enhance both performance and aesthetic appeal. As consumer preferences evolve, the factory's ability to adapt and innovate will be key to staying competitive in the market.

10. The Future of Factory Glass Door Technology in Commercial Settings

The future of factory glass door technology in commercial settings looks promising, with ongoing advancements expected to further enhance energy efficiency, product visibility, and overall functionality. As manufacturers continue to invest in research and development, new innovations such as smart glass technologies and integrated IoT systems may become standard features in display refrigerator doors. The factory's commitment to staying ahead of technological trends ensures that their glass doors will continue to meet the evolving needs of businesses and consumers in a rapidly changing retail landscape.

Image Description