Product Main Parameters

| Component | Specification |

|---|---|

| Glass Type | Tempered Low-E |

| Frame Material | PVC |

| Glass Thickness | 3.2/4mm |

| Insulation | Double or Triple Glazing |

| Insert Gas | Air or Argon |

| Color | Customized |

Common Product Specifications

| Feature | Details |

|---|---|

| Handle | Built-In |

| Temperature Range | -25℃ to 10℃ |

| Application | Coolers, Freezers, Display Cabinets |

| Usage Scenario | Supermarkets, Bars, Offices |

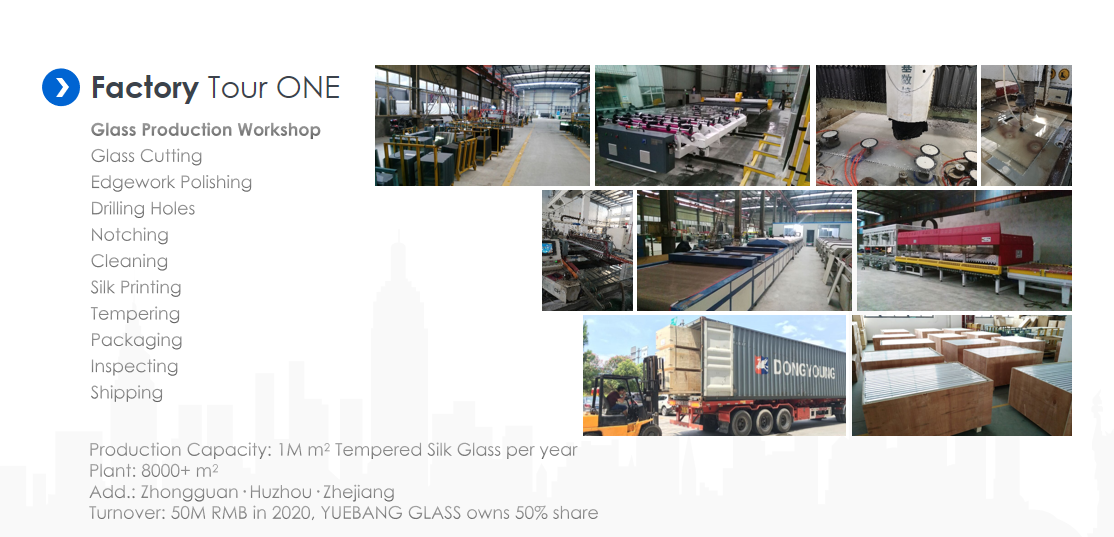

Product Manufacturing Process

The manufacturing process of tempered insulated glass doors involves several critical stages to ensure durability and efficiency. Initially, raw glass sheets undergo precision cutting and edge polishing, preparing them for subsequent treatments. The inclusion of Low-E glass is essential for energy efficiency, reflecting thermal energy while allowing light transmittance. The glazing units are then formed by sealing the edges with butyl and polysulfide sealants, creating air or argon-filled spaces between the panes for insulation. Such intricate processes foster not only aesthetics but also the thermal preservation necessary in refrigeration applications, aligning with industry standards for energy-saving and environmental sustainability.

Product Application Scenarios

The utilization of Beverage Refrigerator Glass Doors spans across numerous environments, catering to different market segments. In the retail sector, these doors are pivotal in ensuring product visibility and maintaining optimal storage conditions, essential for consumer goods like beverages. Hospitality venues, such as bars and restaurants, benefit from their sleek design and functional display, enhancing the customer experience. Furthermore, office spaces often incorporate these doors in break-room appliances, reflecting a modern and energy-efficient ethos. Adherence to established industry research underlines their impact in reinforcing brand presence and operational efficiency across varied commercial settings.

Product After-sales Service

- Free Spare Parts

- 1-year Warranty

- Dedicated Customer Support

Product Transportation

Our products are securely packaged using EPE foam and seaworthy wooden cases to ensure damage-free transit. We ship globally from Shanghai or Ningbo ports, offering reliable delivery options that meet international logistical standards.

Product Advantages

- Customizable color and size for tailored solutions.

- Energy-efficient Low-E glass enhances cooling efficiency.

- Durable construction with PVC frames and tempered glass.

Product FAQ

- Q: Are you a manufacturer?

A: Yes, we are a manufacturer specializing in high-quality glass doors for over 20 years, ensuring reliable and durable products. - Q: What is your minimum order quantity?

A: The MOQ varies by design, typically starting from 50 pieces. Please contact us for specific requirements. - Q: Can I use my logo?

A: Absolutely, we offer customization options including logos to meet your branding needs. - Q: How do you ensure product quality?

A: We have a dedicated laboratory for rigorous quality testing, including thermal and durability tests to meet industry standards. - Q: What is the lead time for orders?

A: Ready stock orders ship within 7 days. Custom orders require 20-35 days post-deposit. - Q: Do you offer warranty?

A: Yes, all products come with a 1-year warranty covering manufacturing defects. - Q: How is the product packaged for shipping?

A: Packaging includes EPE foam and seaworthy wooden cases to prevent any damage during transit. - Q: What payment methods do you accept?

A: We accept T/T, L/C, Western Union, and other major payment methods for flexibility. - Q: Is customization available?

A: Yes, we offer customization in size, color, and additional features to meet specific client requirements. - Q: What are the main features of your glass doors?

A: Our glass doors are customizable, energy-efficient, durable, and feature options like self-closing and heating functions.

Product Hot Topics

- Topic: Importance of Energy Efficiency in Beverage Refrigerators

The demand for energy-efficient appliances is soaring in the commercial refrigeration sector. As leading manufacturers of beverage refrigerator glass doors, our designs incorporate advanced Low-E glass technology, which significantly reduces energy consumption by minimizing heat transfer. This advancement not only aligns with international energy-saving mandates but also offers clients reduced operational costs, making our glass doors a smart investment for any business. - Topic: Customization Trends in Refrigerator Glass Doors

Customization is a growing trend in the refrigerator market, allowing businesses to align appliance aesthetics with their brand identity. Manufacturers now offer various color and size adjustments, ensuring that each glass door is unique. Our customizable beverage refrigerator glass doors cater to this trend, offering bespoke solutions that enhance both practicality and visual appeal in a commercial setting. - Topic: The Role of Tempered Glass in Modern Appliances

Tempered glass has become integral to modern appliance design due to its durability and safety features. When used in refrigerator glass doors, it not only provides a clear view of contents but also withstands temperature fluctuations and impacts. As experienced manufacturers, we ensure our tempered glass doors meet stringent safety and performance standards, providing peace of mind to our clients. - Topic: Enhancing Retail Spaces with Glass Door Refrigerators

Retail environments benefit greatly from beverage refrigerators with glass doors, which offer an inviting glimpse of products while maintaining optimal storage conditions. Our glass doors, designed by expert manufacturers, balance aesthetics and functionality, becoming a focal point in retail spaces that draws customer attention and encourages purchases. - Topic: Innovations in Refrigeration Technology

Refrigeration technology is continually evolving, with advances in glass door design playing a crucial role. Features like self-closing mechanisms and heating options are gaining popularity, enhancing energy efficiency and user convenience. Our cutting-edge beverage refrigerator glass doors incorporate these innovations, setting industry benchmarks in quality and performance. - Topic: Global Supply Chains and Their Impact on Appliance Manufacturing

Global supply chains influence appliance manufacturing, dictating material availability and production timelines. As a leading manufacturer, we navigate these complexities to deliver high-quality beverage refrigerator glass doors worldwide. Our established networks ensure reliable supply chains, allowing us to meet client demands without compromising on quality or delivery times. - Topic: The Environmental Impact of Glass Door Refrigeration

Environmental sustainability is a key consideration in developing glass door refrigeration solutions. Our use of Low-E glass enhances energy efficiency, reducing the carbon footprint of commercial appliances. As conscientious manufacturers, we commit to environmentally friendly practices, ensuring our beverage refrigerator glass doors contribute positively to a sustainable future. - Topic: Customer Satisfaction and After-Sales Support in Appliance Industry

Customer satisfaction hinges on both product quality and after-sales support. Manufacturers like us prioritize these elements, offering comprehensive warranties and responsive customer service. Our beverage refrigerator glass doors are backed by a robust support system, ensuring clients receive prompt assistance, which bolsters trust and long-term relationships. - Topic: The Future of Smart Appliances in Refrigeration

The integration of smart technology in refrigeration is shaping the future of the industry. Smart beverage refrigerator glass doors offer enhanced functionalities like remote temperature monitoring and energy usage tracking, providing users with greater appliance control. As forward-thinking manufacturers, we are at the forefront of this technological revolution, engineering solutions that seamlessly blend innovation with practicality. - Topic: Economic Trends Influencing Appliance Demand

Global economic trends significantly impact the demand for appliances, influencing manufacturing strategies and product offerings. Our company remains agile in responding to these shifts, adapting our beverage refrigerator glass door production to align with market needs. By maintaining a keen awareness of economic landscapes, we ensure our products remain relevant and competitive internationally.

Image Description