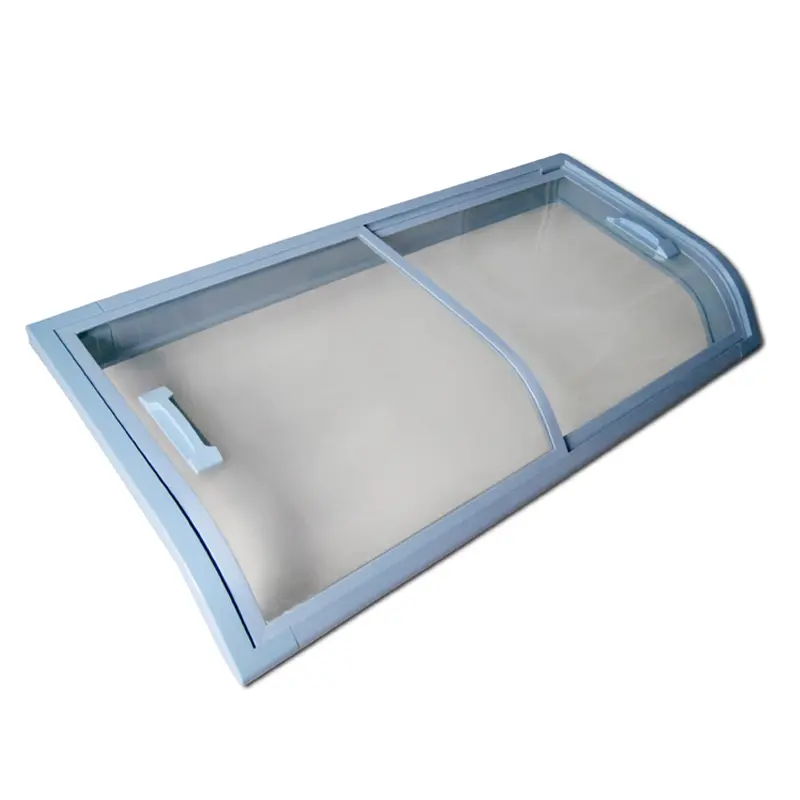

Product Main Parameters

| Product Name | Commercial Deep Island Chest Freezer Flat Sliding Glass Door |

|---|---|

| Glass Material | 4±0.2MM Tempered Low-E Glass |

| Frame Material | ABS, PVC Extrusion Profile |

| Size | Width: 815MM, Length: Customized |

| Frame Color | Gray, Customizable |

| Temperature Range | -30℃ to 10℃ |

Common Product Specifications

| Application | Chest Freezer, Island Freezer, Deep Freezer |

|---|---|

| Package | EPE Foam Seaworthy Wooden Case |

| Service | OEM, ODM |

| After-sales Service | Free Spare Parts |

| Warranty | 1 Year |

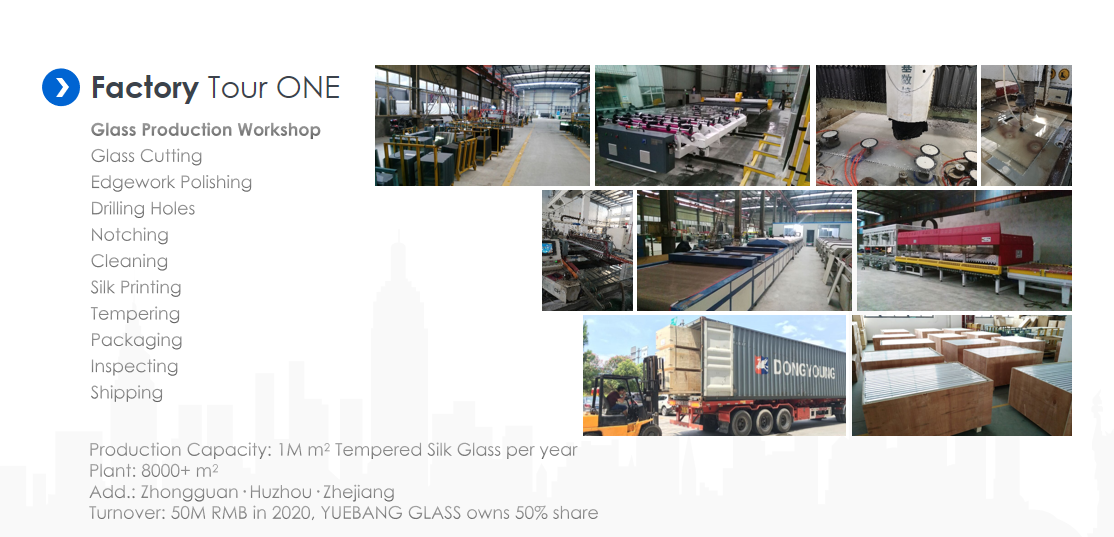

Product Manufacturing Process

The production process of China Freezer Glass Doors involves several critical steps to ensure durability, energy efficiency, and customization. Beginning with glass cutting, the raw glass is precision cut to fit specific design requirements. Edge polishing ensures the glass is smooth and safe for handling. Subsequent drilling and notching prepare the glass for seamless integration with frames and handles. A thorough cleaning step removes impurities, followed by silk printing for branding or design elements. Tempering then enhances the glass' strength and safety. The process culminates in creating hollow insulating structures with PVC extrusion frames, all assembled into a fine commercial product that addresses standard and custom needs. The rigorous standards adhered to ensure that every door produced meets international quality requirements.

Product Application Scenarios

China Freezer Glass Doors are extensively used in various commercial settings. Supermarkets employ these doors in refrigerators for easy visibility of products while maintaining cooling efficiency. Convenience stores utilize them for display coolers, where transparency is crucial for consumer interaction. Restaurant kitchens benefit from these doors by ensuring that ingredients are visible and easily accessible, improving kitchen efficiency. The vending machine industry also incorporates these glass doors to ensure product visibility and security. Each scenario demands specific features like anti-fogging and customization options, which manufacturers can provide to meet diverse environmental needs efficiently.

Product After-sales Service

Our commitment to customer satisfaction extends beyond purchase through comprehensive after-sales service. This includes a one-year warranty covering manufacturing defects and free spare parts provision. Our dedicated support team is available to address any operational issues or inquiries you may encounter.

Product Transportation

We prioritize careful packaging and timely delivery to maintain product integrity during transport. Utilizing EPE foam and seaworthy wooden cases ensures protection against shipping damages. Coordinated logistics management secures prompt arrival at your location.

Product Advantages

- Energy Efficiency: Superior insulation reduces energy costs.

- Durability: Tempered glass offers safety and longevity.

- Customization: Tailored solutions for varied refrigeration units.

- Visibility: Anti-fog technology enhances product display.

- Economical: Cost-effective production without compromising quality.

Product FAQ

- Are you a manufacturer or trading company? We are professional manufacturers dedicated to quality glass door production.

- What is the order MOQ? MOQ varies; contact us with your requirements for precise details.

- Can I customize my glass doors? Yes, we offer customizable options to fit your specific needs.

- How is the warranty covered? Enjoy a one-year warranty with free spare parts for identified defects.

- What payment methods do you accept? We accept T/T, L/C, Western Union, and more.

- What is your lead time? Stock orders ship in 7 days. Customized orders take 20-35 days post-deposit.

- How do you ensure product quality? Rigorous testing and inspections uphold our quality standards.

- Can I use my logo? Yes, you can personalize products with your brand.

- How do you package the products? We use secure packaging to prevent transit damage.

- What benefits come with OEM/ODM services? Tailored manufacturing to your exact design and functionality needs.

Product Hot Topics

- The Rising Demand for Energy-efficient China Freezer Glass Doors: As energy costs rise, businesses are increasingly turning to energy-efficient solutions. Freezer glass doors from leading manufacturers in China minimize heat transfer, thereby significantly reducing energy consumption. By using Low-E glass and incorporating argon gas filling, these doors provide enhanced insulation leading to cost savings. Their rise in popularity underscores the push towards environmentally conscious consumerism.

- Customizable Options for Commercial Refrigeration Needs: Modern businesses need diversification, and customization is at the forefront of this demand. China Freezer Glass Door manufacturers respond by offering tailored designs to fit aesthetic and functional requirements. With options in colors, sizes, and materials, manufacturers provide solutions catering to supermarkets, restaurants, and other commercial spaces, thus showcasing their adaptability and focus on customer satisfaction.

- The Role of Advanced Manufacturing in Quality Assurance: Applying advanced technology in manufacturing processes has become a staple for China Freezer Glass Door manufacturers. From sophisticated cutting techniques to precise thermal tempering, the focus remains on delivering robust and safe products. These technological advancements ensure consistency in quality, demonstrating the industry's commitment to delivering reliable refrigeration solutions worldwide.

- Meeting International Standards in Freezer Glass Doors: Compliance with global quality and safety standards is crucial for China-based manufacturers. By adhering to certifications such as ISO 14001, these manufacturers ensure that their products not only meet but often exceed international regulations. This approach facilitates easier access to global markets where reliability and compliance remain pivotal in selecting refrigeration components.

- The Impact of Eco-Friendly Practices in Manufacturing: As environmental awareness rises, adopting sustainable practices is imperative. Manufacturing processes now incorporate recyclable materials and energy-efficient technologies, reducing the ecological footprint. China Freezer Glass Door manufacturers lead this shift, showcasing their commitment to a sustainable future while maintaining top-tier product quality.

Image Description