| Product Main Parameters | |

|---|---|

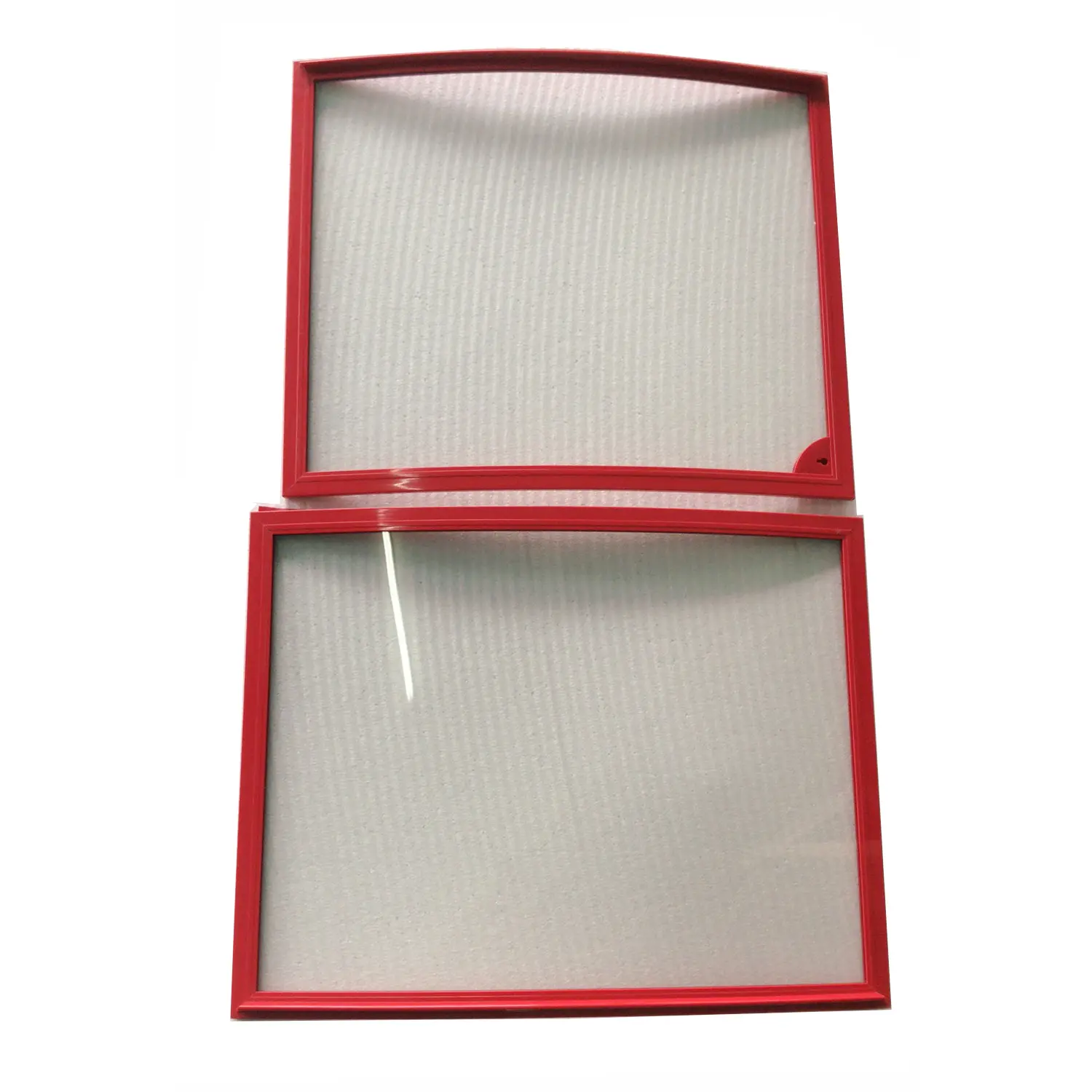

| Product Name | Commercial Deep Island Chest Freezer Flat Sliding Glass Door |

| Glass Material | 4±0.2MM Tempered Low-E glass |

| Frame Material | ABS, PVC extrusion profile |

| Size | Width: 815MM, Length: Customized |

| Temperature | -30℃ to 10℃ |

| Color | Gray, Customizable |

| Common Product Specifications | |

|---|---|

| High Visual Light Transmittance | ≥80% |

| High Solar Energy Transmittance | Yes |

| Reflectance Rate of Far Infrared Radiation | High |

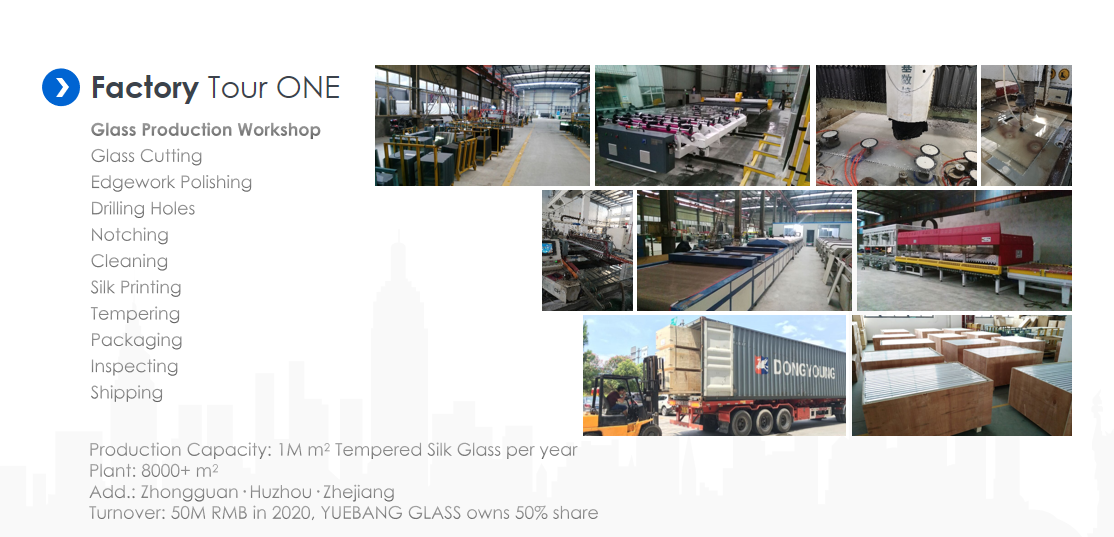

Product Manufacturing Process

Based on authoritative sources in materials engineering, the manufacturing process for tempered glass doors involves rigorous quality checks to ensure durability and efficiency. The process starts with glass cutting, followed by edge polishing, drilling, and notching to create the desired shape and features. Subsequently, silk printing and the application of Low-E coatings enhance the glass's insulation properties. The glass is then tempered using controlled thermal treatments to increase strength. In the assembly phase, the doors are equipped with PVC extrusion frames for structural integrity, and the entire unit undergoes thorough quality inspections before packaging and shipment. This comprehensive process not only ensures product consistency but also positions manufacturers as leaders in the cooler glass door for refrigerator market.

Product Application Scenarios

Cooler glass doors for refrigerators are pivotal in a variety of commercial and retail environments. According to retail management studies, these doors facilitate effective product display, optimizing visibility and consumer access in settings such as supermarkets, convenience stores, and beverage merchants. The incorporation of LED lighting further enhances product appeal, making it easier for customers to perceive available selections, thus promoting impulse purchases and increased sales. Additionally, the energy-efficient nature of these glass doors aligns well with contemporary sustainability goals, enabling store owners to reduce operational costs while maintaining optimal product storage conditions. Overall, manufacturers emphasize the importance of integrating cooler glass doors for refrigerators into retail strategies to boost customer engagement and environmental responsibility.

Product After-Sales Service

Yuebang offers comprehensive after-sales service including a one-year warranty, free spare parts, and responsive customer support to address any issues with the cooler glass doors for refrigerators.

Product Transportation

The cooler glass doors are securely packed using EPE foam and seaworthy wooden cases (Plywood Carton) to ensure safe transit. We work with reliable logistics providers for timely and secure delivery worldwide.

Product Advantages

- Improved product visibility and customer engagement in retail settings.

- Energy efficiency through improved insulation and Low-E glass coatings.

- Durability with high-quality tempered glass construction.

Product FAQ

- Q: Are you manufacturers or trading companies?

A: We are manufacturers specializing in cooler glass doors for refrigerators, with a vast experience of over 20 years. - Q: Can the size of the doors be customized?

A: Yes, as leading manufacturers, we offer customization of door sizes to fit specific refrigerator models. - Q: What materials are used in the frame construction?

A: The frame is constructed using durable ABS and PVC extrusion profiles for long-lasting performance. - Q: How does the Low-E glass improve energy efficiency?

A: Low-E glass minimizes heat transfer, helping to maintain stable internal temperatures and reduce energy use. - Q: Is product visibility maintained even in low-light conditions?

A: Yes, our cooler glass doors for refrigerators are equipped with LED lighting for enhanced visibility. - Q: What temperature range can the doors withstand?

A: Our glass doors are designed to function effectively between -30℃ and 10℃. - Q: How can I place an order?

A: Orders can be placed by contacting us directly. We accept various payment methods including T/T and L/C. - Q: How long does it take to receive a customized order?

A: Custom orders typically take between 20-35 days post-deposit, depending on the complexity and quantity. - Q: What should be done if the glass door gets damaged during shipping?

A: Our after-sales service includes free spare parts to address any damages sustained during shipping. - Q: Are your products environmentally friendly?

A: As responsible manufacturers, our cooler glass doors are designed for energy efficiency, aligning with environmental sustainability goals.

Product Hot Topics

- How Manufacturers Innovate Energy Efficiency in Cooler Glass Doors for Refrigerators

In the competitive landscape of refrigeration solutions, manufacturers are continuously innovating to enhance the energy efficiency of cooler glass doors for refrigerators. Notably, the use of Low-E glass has revolutionized thermal management, significantly reducing energy consumption. Advances in LED lighting further complement this by ensuring visibility without excessive energy drain. These innovations not only meet consumer demand for sustainable products but also help businesses manage operational costs effectively. The synergy between technological advancements and environmental conservation is a promising trend driving the future of refrigeration solutions. - The Role of Visibility and Design in Retail Sales with Cooler Glass Doors for Refrigerators

Visibility is a crucial factor in retail sales, and this is where cooler glass doors for refrigerators play an indispensable role. The clear glass facilitates an unobstructed view of the products, encouraging potential customers to engage directly with the offerings. Furthermore, manufacturers focus on aesthetically pleasing designs that integrate seamlessly into modern retail environments. The combination of functionality and design not only enhances shopper experience but also serves as a powerful marketing tool, effectively influencing purchase decisions and boosting sales. - Challenges in Manufacturing Cooler Glass Doors for Refrigerators

Manufacturers face several challenges in the production of cooler glass doors for refrigerators, notably in achieving the perfect balance between durability, energy efficiency, and aesthetic appeal. The manufacturing process requires precise engineering to create doors that can endure temperature fluctuations while providing excellent insulation. Additionally, the integration of smart technologies, such as IoT-enabled sensors for temperature monitoring, adds another layer of complexity. Addressing these challenges necessitates continuous research and development efforts, ensuring that the end products meet high industry standards and customer expectations. - Sustainability Trends Influencing Manufacturers of Cooler Glass Doors for Refrigerators

Sustainability is at the forefront of innovations in the manufacturing sector, including cooler glass doors for refrigerators. Manufacturers are increasingly adopting green practices by using recyclable materials and energy-efficient technologies. This shift not only fulfills regulatory requirements but also aligns with global environmental goals, catering to the growing demand for eco-friendly products. As sustainability becomes a pivotal selling point, manufacturers are poised to lead the charge in reducing the carbon footprint of commercial refrigeration solutions globally. - The Future of Smart Technologies in Cooler Glass Doors for Refrigerators

As technology advances, manufacturers are exploring smart technologies to revolutionize cooler glass doors for refrigerators. The future may see the integration of digital interfaces on glass doors that display product information or track inventory levels. Smart sensors could monitor door usage patterns to optimize energy efficiency further. These innovations could transform how businesses manage refrigerated goods, offering enhanced control, efficiency, and customer interaction capabilities. As the market evolves, manufacturers are set to play a pioneering role in adopting these cutting-edge technologies. - Why Durable Tempered Glass Is Essential for Cooler Doors in Commercial Settings

Durability is a cornerstone of cooler glass doors, especially in high-traffic commercial settings. Tempered glass is the material of choice due to its strength and ability to withstand impacts and temperature variations. Manufacturers prioritize tempered glass to ensure safety and longevity, reducing the risk of breakage and ensuring consistent performance. This focus on durability not only protects the products inside the refrigerators but also minimizes potential hazards in public areas, making tempered glass an essential component of commercial refrigeration solutions. - Comparing Different Frame Materials Used by Manufacturers in Cooler Glass Doors for Refrigerators

Frame materials are a critical consideration for manufacturers when constructing cooler glass doors for refrigerators. The choice between ABS plastic and PVC extrusion profiles often depends on specific application needs. ABS plastic is known for its impact resistance and stability, making it ideal for high-demand environments. Meanwhile, PVC profiles offer customization flexibility and cost-effectiveness. By selecting the appropriate frame material, manufacturers can tailor their products to meet diverse commercial requirements, ensuring both functionality and aesthetic appeal. - Customization Trends in Cooler Glass Doors for Refrigerators

Customization is becoming increasingly significant as manufacturers cater to the specific needs of different sectors. This trend includes offering tailored sizes, color schemes, and technological integrations that align with brand aesthetics and functional requirements. The ability to customize not only adds value to the product but also enhances customer satisfaction by delivering solutions that meet individual business needs. As the demand for personalized solutions grows, manufacturers are embracing this trend, setting new standards in the cooler glass door market. - Importance of Quality Control in the Manufacturing of Cooler Glass Doors for Refrigerators

Quality control is paramount in the production of cooler glass doors for refrigerators, ensuring that each unit meets precise standards for safety, performance, and durability. Manufacturers implement rigorous testing protocols, including thermal shock and condensation tests, to guarantee product reliability. These quality assurances not only foster consumer trust but also protect the manufacturer's reputation. As industry competition intensifies, unwavering commitment to quality control becomes a distinguishing factor for manufacturers seeking to maintain leadership in the market. - Exploring Insulation Technologies in Cooler Glass Doors for Refrigerators

Insulation technology is a critical focus for manufacturers aiming to enhance the energy efficiency of cooler glass doors for refrigerators. By employing advanced materials like Low-E coatings and argon gas fill, manufacturers can significantly reduce thermal transfer, maintaining stable interior temperatures. These technologies help in lowering energy consumption, aligning with the global emphasis on sustainability. As innovations continue, manufacturers are poised to offer even more efficient insulation solutions, contributing to a greener and more cost-effective future in refrigeration.

Image Description