Product Main Parameters

| Feature | Details |

|---|---|

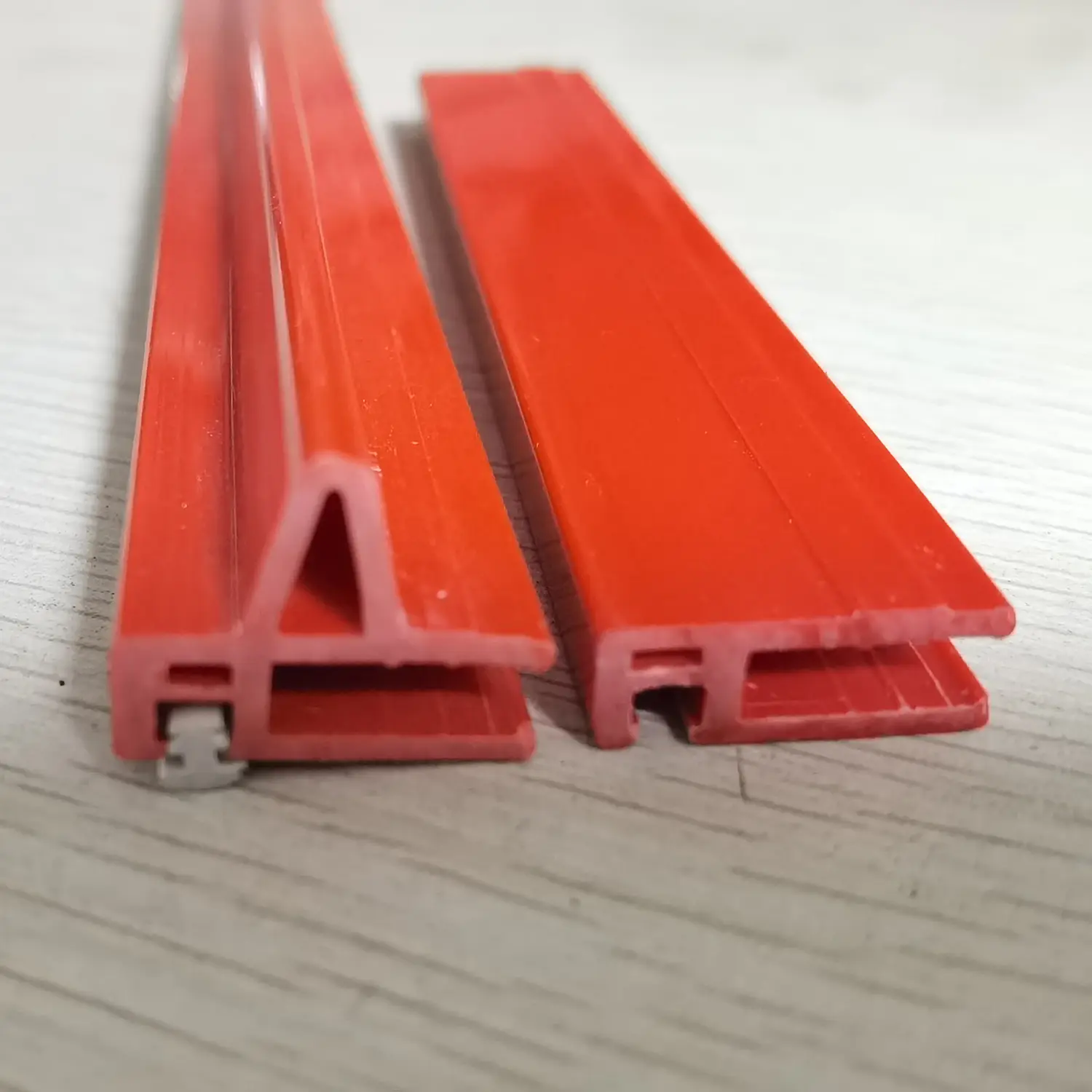

| Material | Aluminum Frame, Tempered Low-E Glass |

| Frame | PVC Extrusion Profile, ROHS compliant |

| Glass Thickness | 4mm |

| Size | Customized |

| Temperature Range | -25°C to -10°C |

| Application | Chest Freezer, Ice Cream Freezer, Island Freezer |

| Accessories | Key lock |

| Warranty | 1 Year |

Common Product Specifications

| Specification | Description |

|---|---|

| Light Transmittance | High (Low-E Glass) |

| Solar Energy Transmittance | High (Low-E Glass) |

| Reflectance | High rate of far infrared radiation (Low-E Glass) |

| Color Options | Gray, Green, Blue, etc. |

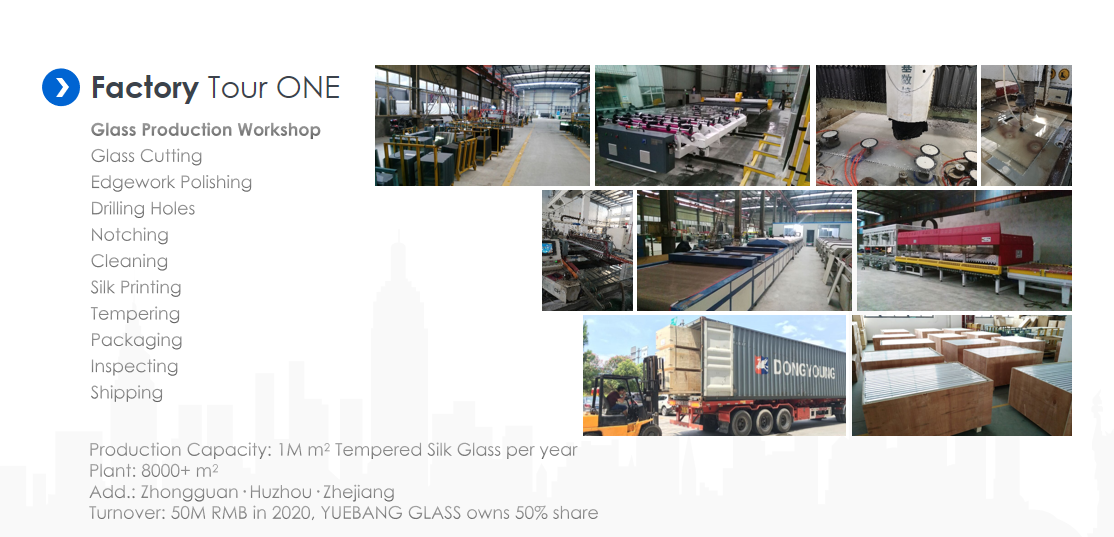

Product Manufacturing Process

Drawing from authoritative sources on glass and materials engineering, the manufacturing process of freezer aluminum frame glass doors involves multiple precise steps to ensure durability and performance. Initially, the glass is cut and polished, followed by the drilling of holes and notching. It is then meticulously cleaned and subjected to silk printing before being tempered to meet safety standards. The subsequent assembly involves creating insulated glass with specialized gas fills, enhancing thermal efficiency. The aluminum frame is extruded, and the glass is securely fixed with PVC profiles. Rigorous quality checks are conducted, including thermal shock and condensation tests, to guarantee product reliability. This systematic approach results in a high-performance product that aligns with manufacturers' standards for freezer aluminum frame glass doors.

Product Application Scenarios

As discussed in scholarly articles on refrigeration technology, freezer aluminum frame glass doors have diverse applications, primarily in retail and commercial settings. They are favored in supermarkets and convenience stores, providing an effective display of frozen products while maintaining optimal internal temperatures. These doors are also gaining traction in residential kitchens, where they contribute to a sleek, modern aesthetic. Their robust insulation and visibility features make them ideal for medical facilities requiring stringent temperature control for sensitive supplies. The integration of LED lighting further enhances their utility across these varied environments, making them a versatile choice for manufacturers worldwide.

Product After-Sales Service

Yuebang offers comprehensive after-sales support for freezer aluminum frame glass doors, including free spare parts within the warranty period, technical assistance, and customer service to address any concerns swiftly.

Product Transportation

Products are securely packaged using EPE foam and seaworthy wooden cases (Plywood Carton) to ensure damage-free transportation to global destinations.

Product Advantages

- Enhanced Energy Efficiency

- Superior Insulation

- Robust Durability

- Clear Visibility

- Aesthetic Design

Product FAQ

- Q: Are you a manufacturer?

A: Yes, we are manufacturers specializing in freezer Aluminum Frame glass Doors with over 20 years of industry experience.

- Q: What is your MOQ?

A: The MOQ varies by design; please contact us with your specifications for detailed information.

- Q: Can I use my logo?

A: Yes, we offer customization options including logo placement on freezer aluminum frame glass doors.

- Q: How long is the warranty period?

A: We provide a one-year warranty for our freezer aluminum frame glass doors.

- Q: What payment methods do you accept?

A: We accept T/T, L/C, Western Union, and other standard payment terms.

- Q: Can I customize the product?

A: Yes, customization is available for size, color, and other specifications to meet your needs.

- Q: What are the lead times?

A: Standard lead time for stock products is 7 days; customized orders may take 20-35 days post-deposit.

- Q: What are the advantages of aluminum frame glass doors?

A: They offer enhanced energy efficiency, visibility, and meet manufacturers' quality standards, making them ideal for varied applications.

- Q: How are the products packaged for shipping?

A: Products are packed using EPE foam and sturdy wooden cases to ensure safe transportation.

- Q: Where are your key markets?

A: Our products are exported globally, with key markets in the USA, UK, Japan, Korea, India, and Brazil.

Product Hot Topics

- Durability of Freezer Aluminum Frame Glass Doors

Manufacturers praise the durability of freezer Aluminum Frame glass Doors due to their robust construction. Aluminum is known for its corrosion resistance and lightweight properties, which make the frames resilient under frequent use. The tempered Low-E glass further enhances longevity by resisting shattering, making it an ideal choice for both commercial and residential refrigeration units. By combining these materials, manufacturers have created a product that withstands the challenges of continuous operation while maintaining aesthetic appeal, reinforcing its reputation as a reliable refrigeration solution.

- Energy Efficiency Benefits

Freezer Aluminum Frame glass Doors are celebrated for their energy efficiency, a key focus for manufacturers in today’s eco-conscious market. The Low-E glass plays a crucial role by minimizing thermal transfer, which helps in reducing energy consumption. Additionally, the frame construction, often featuring thermal breaks, helps maintain consistent internal temperatures. As a result, these doors contribute to lowering operational costs, making them a favored choice in settings where energy conservation is paramount. This energy efficiency aligns with global sustainability goals, positioning manufacturers at the forefront of green technology.

- Customization Versatility

One of the standout features of freezer Aluminum Frame glass Doors is their customization versatility, a quality manufacturers emphasize. With the ability to tailor size, color, and glazing options, these doors can be adapted to specific needs, enhancing compatibility with various refrigeration systems. Whether for a retail environment, a residential kitchen, or a medical facility, customization ensures that the doors meet both functional and aesthetic requirements. This flexibility makes them a top choice for those seeking products tailored to their unique specifications.

- Application in Commercial Settings

In commercial settings, freezer Aluminum Frame glass Doors are invaluable for enhancing product display while maintaining temperature integrity. Their clear visibility encourages consumer interaction without compromising the internal climate, reducing energy spikes typical with frequent door openings. The integration of LED lighting further boosts product appeal, making them particularly effective in supermarket and restaurant environments. Manufacturers highlight these features as key drivers of enhanced customer experience and operational efficiency, solidifying the doors' place in the commercial refrigeration market.

- Technological Advancements in Manufacturing

The manufacturing of freezer Aluminum Frame glass Doors involves cutting-edge technology and processes that ensure superior product quality. The use of advanced machinery, like flat/curved tempered machines and glass cutting systems, allows manufacturers to maintain precision and consistency across production. Regular technological upgrades ensure that products meet evolving industry standards, reinforcing manufacturers' commitment to delivering state-of-the-art solutions. These advancements underscore the industry's adaptability and continuous pursuit of innovation.

- Role of Insulation in Efficiency

Insulation is a critical component in the design of freezer Aluminum Frame glass Doors, and manufacturers have focused on enhancing this feature to maximize efficiency. By using double or triple glazing and introducing gas fills like argon, these doors achieve superior thermal insulation. The result is a significant reduction in energy loss and improved maintenance of internal temperatures. This focus on insulation not only improves efficiency but also extends the lifespan of refrigeration units, saving users on repairs and replacements.

- Market Trends and Consumer Demand

Manufacturers are seeing a growing demand for freezer Aluminum Frame glass Doors as consumer preferences shift towards energy-efficient and visually appealing refrigeration solutions. With the rise of modern retail environments and eco-friendly practices, these doors cater to both functional and aesthetic needs. Their ability to seamlessly integrate into various settings while offering significant energy savings aligns with current market trends, making them a popular choice among buyers conscious of sustainability and cost-efficiency.

- Importance of Quality Control

Quality control is paramount in the production of freezer Aluminum Frame glass Doors, and manufacturers implement rigorous testing to ensure product reliability. By conducting tests such as thermal shock and condensation resistance, manufacturers can offer doors that meet high performance standards. This commitment to quality assurance not only protects brand reputation but also provides peace of mind to customers, knowing they are investing in a trusted product. Enhanced quality control measures also streamline production processes and reduce waste.

- Impact of Aesthetic Design

The aesthetic design of freezer Aluminum Frame glass Doors is a significant selling point for manufacturers, as it complements modern interior styles in both commercial and residential applications. The sleek lines and customizable finishes, including anodized or powder-coated options, allow these doors to enhance rather than detract from the visual appeal of their surroundings. This attention to design detail, combined with their functional benefits, makes them a sought-after choice among designers and consumers alike.

- International Demand and Export Strategy

Manufacturers of freezer Aluminum Frame glass Doors are actively expanding their global reach by developing strategies that cater to international markets. With an established presence in key regions like the USA, UK, Japan, and Brazil, they are positioned to meet diverse consumer needs. Continuous improvement in design and technology ensures that these doors remain competitive on a global scale. Manufacturers leverage their adaptability to different regulatory standards, ensuring compliance across borders and enhancing their appeal in the global marketplace.

Image Description