Product Main Parameters

| Type | Freezer Tempered Low-E Glass Lid |

|---|---|

| Glass Thickness | 6mm (customizable) |

| Temperature Range | -30℃ to 10℃ |

| Available Shapes | Flat, Curved |

| Color | Clear |

Common Product Specifications

| Material | Tempered Low-E Glass |

|---|---|

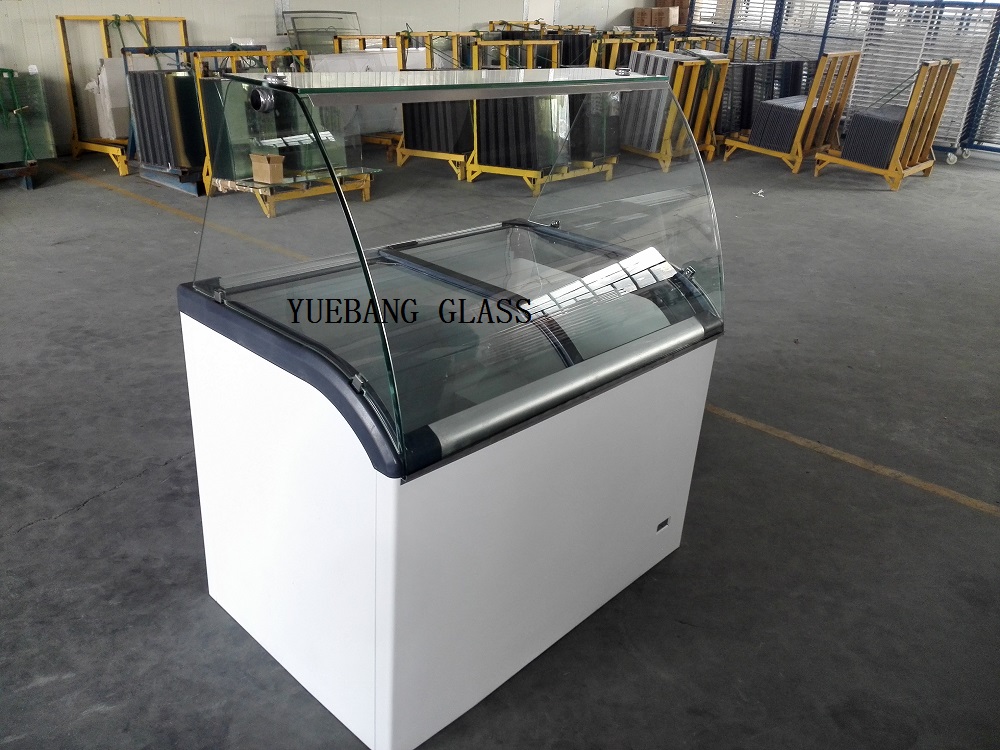

| Application | Ice Cream Display Cabinet |

| Packaging | EPE foam Seaworthy wooden case (Plywood Carton) |

| Services | OEM, ODM |

| Warranty | 1 Year |

Product Manufacturing Process

The manufacturing process of freezer tempered low-E glass begins with high-quality raw glass, which undergoes rigorous inspections to ensure its suitability for tempering. The glass is then heated to around 620°C before being rapidly cooled, creating a balance of compressive and tensile stresses that significantly enhances its strength. A low-E coating is then applied, which is a crucial step for enhancing energy efficiency. High-precision machinery ensures this coating is uniformly applied. The final product is inspected under various tests such as thermal shock and impact resistance to guarantee performance standards. This process ensures that manufacturers produce freezer tempered low-E glass optimized for modern energy-efficient refrigeration demands.

Product Application Scenarios

Freezer tempered low-E glass is widely employed in commercial and residential refrigeration settings, including supermarkets, restaurants, and homes. Its primary role is in maintaining optimal thermal conditions within freezers, vital for food preservation and energy savings. The high insulation performance helps minimize cold air loss, crucial in environments where frequent opening and closing occur. Its durability also suits high-traffic areas. As energy efficiency standards grow more stringent, these glass solutions meet and exceed requirements by reducing refrigeration load and thus operational costs for businesses.

Product After-sales Service

Ensuring customer satisfaction, we provide free spare parts for one year covering defects in materials or workmanship. Our dedicated support team is available to assist with any inquiries or issues, ensuring the functionality and longevity of our products. Training for maintenance and best use practices can be arranged upon request.

Product Transportation

We ensure safe and efficient transportation of freezer tempered low-E glass products by utilizing reinforced packaging solutions such as EPE foam and plywood cartons, minimizing the risk of damage during transit. Shipping logistics are managed by experienced partners to guarantee timely delivery worldwide.

Product Advantages

- High durability and safety due to tempered glass properties.

- Superior energy efficiency from the low-E coating.

- Customizable dimensions and shapes for diverse applications.

- Optimal thermal performance reducing refrigeration costs.

Product FAQ

1. What makes tempered glass suitable for freezer applications?

Manufacturers utilize tempered glass for freezer applications because its process of heating and rapid cooling enhances its strength and safety, crucial for environments prone to impact and temperature fluctuations. This makes tempered glass an ideal choice for robust freezer doors that maintain insulation integrity under frequent use.

2. How does the low-E coating affect energy efficiency?

The low-E coating applied by manufacturers helps in minimizing infrared and ultraviolet light transmission while allowing natural light through, effectively reducing heat transfer. This trait significantly lowers the refrigeration load, resulting in substantial energy savings, which is a priority in modern energy-conscious enterprises.

3. Can the size of the glass lid be customized?

Yes, manufacturers offer customization options for the size of the glass lid. By providing a drawing or sample, customers can request specific dimensions and shapes to fit their particular refrigeration units, ensuring optimal functionality and aesthetics for various settings.

4. What are the cleaning recommendations for low-E glass?

To maintain the clarity and efficiency of the low-E coating, manufacturers recommend using a soft cloth with mild, non-abrasive cleaning solutions. Avoid harsh chemicals or rough materials that might scratch or damage the coating, preserving the glass’s energy efficiency and appearance.

5. What warranty is provided for the freezer tempered low-E glass lid?

Manufacturers provide a 1-year warranty covering defects in materials and workmanship. This warranty ensures that any issues arising under normal use conditions within the specified period are addressed promptly, safeguarding the customer’s investment in high-quality refrigeration solutions.

6. Are there best practices for installing these glass lids?

Proper installation is critical to maximizing the benefits of freezer tempered low-E glass. Manufacturers recommend ensuring that trained professionals carry out the installation to avoid issues such as thermal bridging and ensure a secure fit, maintaining energy efficiency and safety standards in refrigeration units.

7. How do manufacturers test the quality and durability of the glass?

Manufacturers conduct a series of tests including thermal shock, impact resistance, and condensation trials to validate the performance standards of freezer tempered low-E glass. These rigorous assessments ensure the glass meets energy efficiency and safety expectations before reaching the consumer market.

8. Does low-E glass affect visibility inside the freezer?

No, manufacturers design low-E glass to maintain high visual light transmittance while reducing infrared and UV light. This characteristic ensures that visibility inside the freezer is not compromised, presenting contents clearly while enhancing thermal efficiency.

9. What role does the glass lid play in overall refrigeration efficiency?

Freezer tempered low-E glass lids serve as a critical barrier against thermal exchange, minimizing cold air loss and reducing compressor workload. Manufacturers highlight that this efficiency plays a vital role in lowering energy costs, prolonging equipment life, and ensuring consistent refrigeration performance.

10. Are there any industry standards governing freezer glass?

Yes, manufacturers adhere to stringent industry standards such as ASTM and EN for safety, durability, and thermal performance. These standards ensure that freezer tempered low-E glass products meet the regulatory requirements for energy efficiency, safety, and reliability, consistent with industry best practices.

Product Hot Topics

1. Importance of Energy Efficiency in Modern Refrigeration

Today, manufacturers prioritize energy efficiency due to rising operational costs and environmental concerns. Freezer tempered low-E glass plays a pivotal role by reducing energy consumption through superior thermal insulation, making it an indispensable component in refrigerators seeking to lower their carbon footprint and enhance economic viability.

2. Technological Advances in Glass Manufacturing

Recent technological advances in glass manufacturing have allowed manufacturers to produce ultra-efficient tempered low-E glass tailored for the refrigeration industry. Precision coating techniques and automated production lines enhance quality and performance, leading to more sustainable and cost-effective refrigeration solutions.

3. Customization in Refrigeration Solutions

Manufacturers now offer bespoke solutions for refrigeration needs, with customizable freezer tempered low-E glass products. This adaptability allows businesses and residential users to specify product dimensions and features that align perfectly with their unique requirements, enhancing both functionality and aesthetic appeal.

4. Safety Standards in Glass Manufacturing

The stringent safety standards adhered to by manufacturers ensure that freezer tempered low-E glass products not only meet but exceed necessary guidelines. This commitment to safety is crucial in maintaining the integrity of both commercial and residential refrigeration environments, safeguarding users and stored contents alike.

5. Sustainability in Refrigeration Design

Sustainability is at the forefront of refrigeration design today. Manufacturers integrate freezer tempered low-E glass due to its ability to deliver outstanding energy savings and reduce environmental impact. This aligns with global initiatives targeting significant reductions in carbon emissions across industries.

6. Global Trends in Freezer Glass Applications

Recent global trends highlight an increased adoption of freezer tempered low-E glass in diverse markets, driven by heightened awareness of energy costs and efficiency. Manufacturers report a surge in demand across various sectors including hospitality, retail, and domestic installations, reflecting a broader shift towards energy-conscious solutions.

7. The Role of Glass Coatings in Thermal Insulation

Manufacturers recognize that glass coatings, specifically low-E variants, are critical in achieving optimal thermal insulation. These coatings minimize heat exchange, contributing to substantial energy savings and enhanced performance across refrigeration units, thereby becoming a staple in contemporary appliance design.

8. Enhancing Product Longevity with Advanced Glass Solutions

Freezer tempered low-E glass not only improves energy efficiency but also product longevity. Manufacturers emphasize that the durability of these glass solutions reduces maintenance needs and extends the service life of refrigeration units, offering long-term cost benefits for businesses and homeowners alike.

9. Future Innovations in Refrigeration Technology

The future of refrigeration technology promises continued innovation, with manufacturers exploring new ways to integrate cutting-edge glass solutions like freezer tempered low-E glass. Advances in nanotechnology and smart glass could soon redefine energy efficiency and user interaction in next-gen refrigeration systems.

10. Comparing Freezer Glass Options

When selecting freezer glass, manufacturers often highlight the superior properties of tempered low-E glass over standard options. The comparison typically centers around enhanced durability, safety, and energy efficiency, with low-E variants offering significant advantages that align with modern refrigeration needs.

Image Description

There is no picture description for this product