Product Main Parameters

| Parameter | Details |

|---|---|

| Glass Type | Tempered Float Glass |

| Glass Thickness | 3mm-19mm |

| Shape | Flat, Curved |

| Size | Max. 3000mm x 12000mm, Min. 100mm x 300mm, Customized |

| Color | Clear, Ultra Clear, Blue, Green, Grey, Bronze, Customized |

Common Product Specifications

| Specification | Details |

|---|---|

| Edge | Fine Polished Edge |

| Structure | Hollow, Solid |

| Applications | Buildings, Refrigerators, Doors and Windows, Display Equipment |

| Package | EPE foam Seaworthy wooden case (Plywood Carton) |

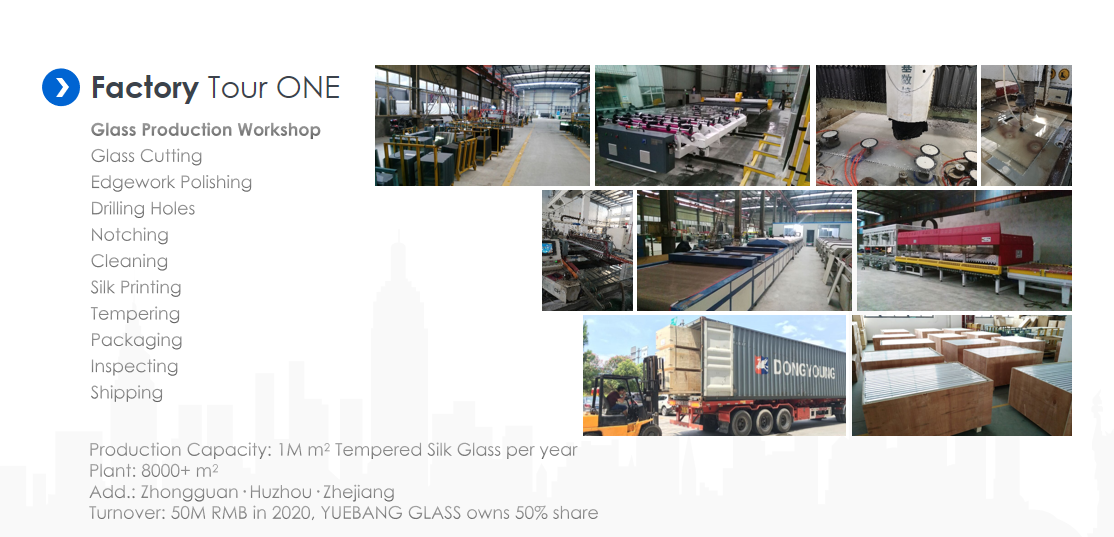

Product Manufacturing Process

Freezer curved glass tempered float glass manufacturing involves multiple precision steps to ensure optimal quality and performance. Initially, high-grade annealed glass is selected and cut to the required dimensions using specialized glass cutting machines. Following this, the glass undergoes edge polishing to achieve smooth finishes and precise dimensions, crucial for both aesthetic appeal and functional integration in freezer applications. Drilling, notching, and cleaning steps follow, preparing the glass for silk printing or other customizations as needed. The crucial tempering process involves heating the glass to approximately 620 degrees Celsius, then rapidly cooling it to induce compressive stresses on the surface while tensile stress remains in the core. This process enhances the strength and thermal stability of the glass, making it ideal for freezer environments. Finally, the glass is assembled into hollow or solid structures as required, packaged securely for shipment, and transported to meet global demand. These comprehensive processes underscore Yuebang Glass's commitment to quality and innovation, setting a benchmark in the industry for both safety and performance.

Product Application Scenarios

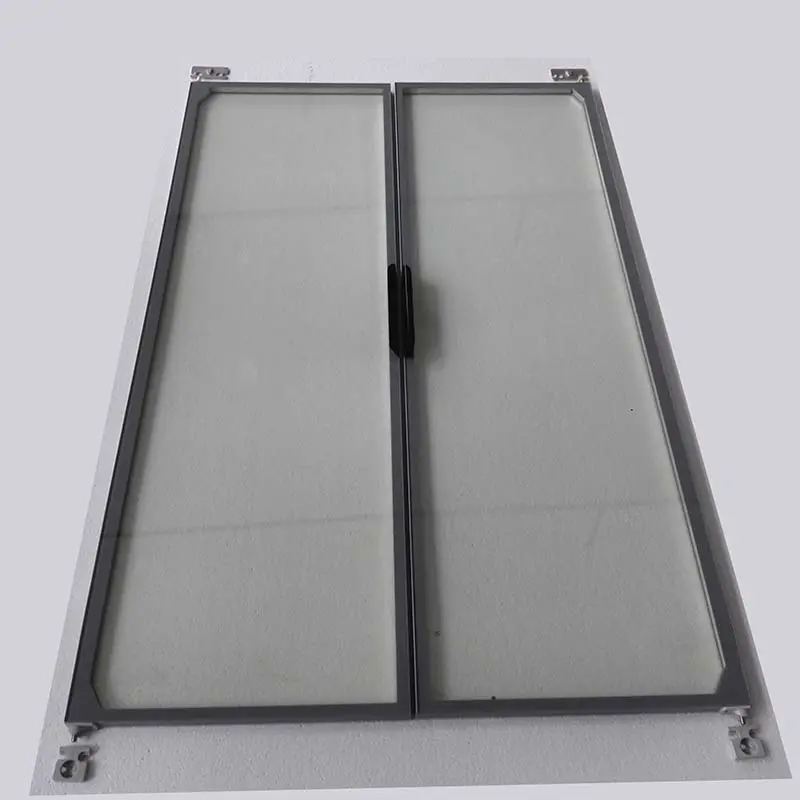

The freezer curved glass tempered float glass is extensively utilized across a variety of commercial settings where durability and visibility are paramount. Its applications range from supermarkets to specialty food shops, where display freezers benefit from the enhanced aesthetic appeal and structural integrity provided by the curved design. Additionally, sliding glass doors in commercial freezers utilize this glass for its robust nature, capable of withstanding frequent use while maintaining optimal insulation properties. Architects and designers often select this glass for custom designs, leveraging its flexibility in shaping unique forms that enhance both function and style. These scenarios highlight the glass's versatility, aligning with evolving industry standards and environmental requirements, contributing significantly to both energy efficiency and customer satisfaction.

Product After-Sales Service

Yuebang Glass offers comprehensive after-sales service for our freezer curved glass tempered float glass, ensuring customer satisfaction and long-term product performance. Our service includes a one-year warranty, providing free spare parts in the event of manufacturing defects. Our dedicated support team is available for consultation and assistance with installation, maintenance, and troubleshooting, ensuring seamless integration into your freezer units. Additionally, we prioritize customer feedback to continuously improve our product offerings and service quality.

Product Transportation

Ensuring the safe delivery of our freezer curved glass tempered float glass is paramount. We utilize protective packaging with EPE foam and seaworthy wooden cases to safeguard against damage during transit. Our shipping partners are selected based on reliability and efficiency, offering flexible shipping options via Shanghai or Ningbo ports to meet global distribution needs.

Product Advantages

- Strength and Safety: Tempered glass is significantly stronger and safer, breaking into small blunt pieces.

- Thermal Stability: Withstands temperature fluctuations, ideal for freezer settings.

- Clarity: Exceptional clarity enhances product visibility in display units.

- Customization: Offers a range of colors, shapes, and sizes for diverse applications.

Product FAQ

- What is the minimum order quantity?

The minimum order quantity varies depending on the design specifications. Please contact us with your specific design requirements for precise MOQ details.

- Can I customize the glass with my logo?

Yes, we offer customization options, including the ability to incorporate your logo onto the glass surface.

- What are the available payment methods?

We accept T/T, L/C, Western Union, and other payment terms for your convenience.

- How long is the lead time for orders?

The lead time is approximately 7 days if stock is available. For customized products, it ranges from 20-35 days post-deposit.

- What warranty do you offer?

We provide a one-year warranty with free spare parts for any manufacturing defects.

- What distinguishes your tempered glass from others in the market?

Our tempered glass stands out due to its superior strength, clarity, and customization options, all at competitive pricing.

- Is OEM/ODM service available?

Absolutely, we offer both OEM and ODM services to tailor products according to your specifications.

- How is the glass packaged for shipment?

Each piece is carefully packaged using EPE foam and placed in sturdy seaworthy wooden cases to ensure safe transportation.

- Can the glass be used for applications other than freezers?

Yes, our glass is versatile and suitable for a range of applications including buildings, doors, windows, and display equipment.

- How do you ensure quality control during production?

We maintain rigorous quality control with regular equipment maintenance, adherence to ISO standards, and comprehensive testing protocols.

Product Hot Topics

- The Future of Freezer Glass: Innovations and Trends

As manufacturers like Yuebang Glass continue to innovate, the future of freezer curved glass tempered float glass is shaping to be both technologically advanced and environmentally sustainable. Current trends focus on enhancing energy efficiency and incorporating smart technologies, such as integrated heating elements to reduce condensation. The demand for customizable solutions is rising, driven by a need for unique design aesthetics in commercial spaces. These advancements not only improve functionality but also contribute significantly to operational cost savings and environmental conservation.

- Safety and Durability: Why Tempered Glass Leads the Industry

In commercial settings, the choice of materials is crucial for ensuring safety and longevity. Freezer curved glass tempered float glass is at the forefront of the industry, known for its ability to withstand impacts and thermal stress. Manufacturers prioritize these safety features to meet rigorous industry standards and protect customers and employees from harm. The inherent durability of tempered glass reduces the need for frequent replacements, offering businesses a cost-effective and reliable solution for cold storage applications.

Image Description