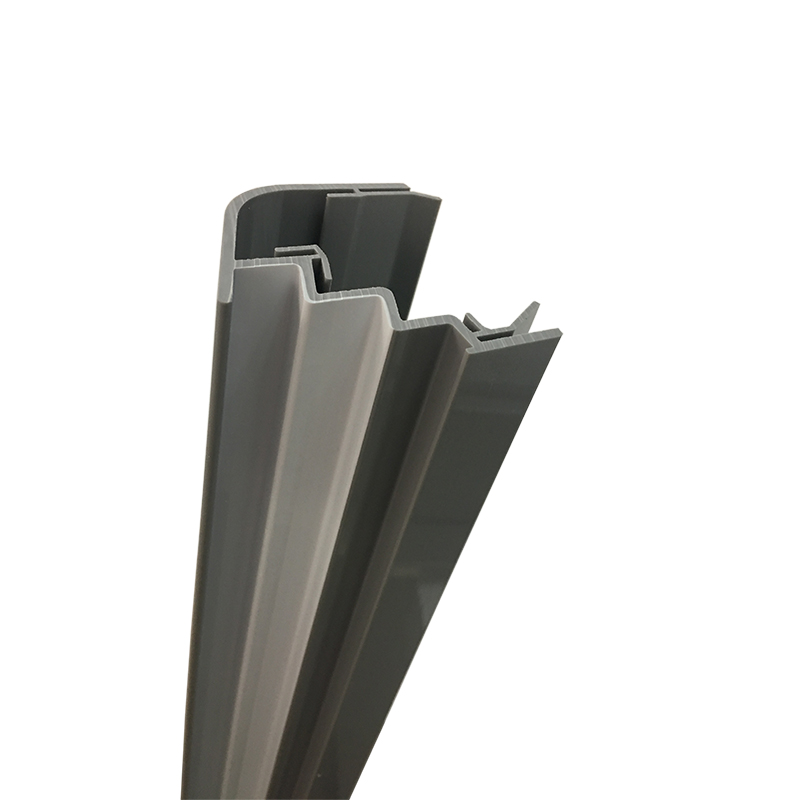

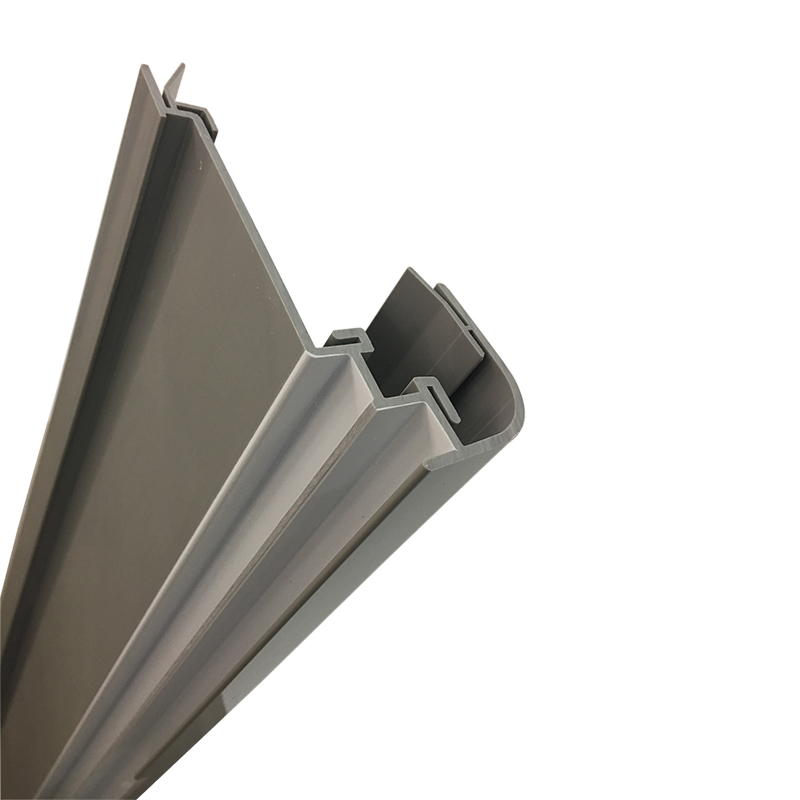

Product Details

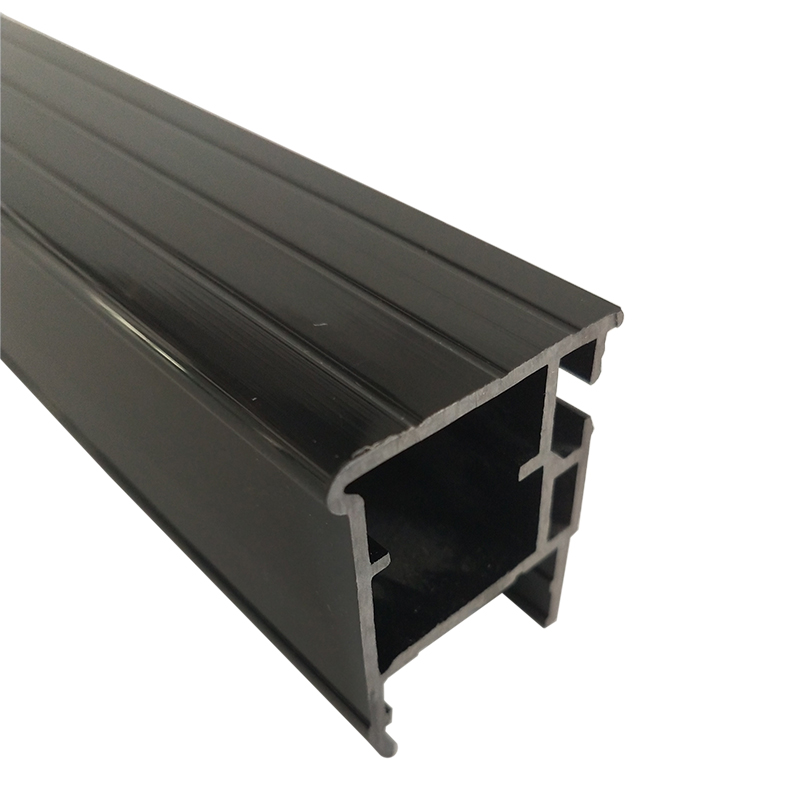

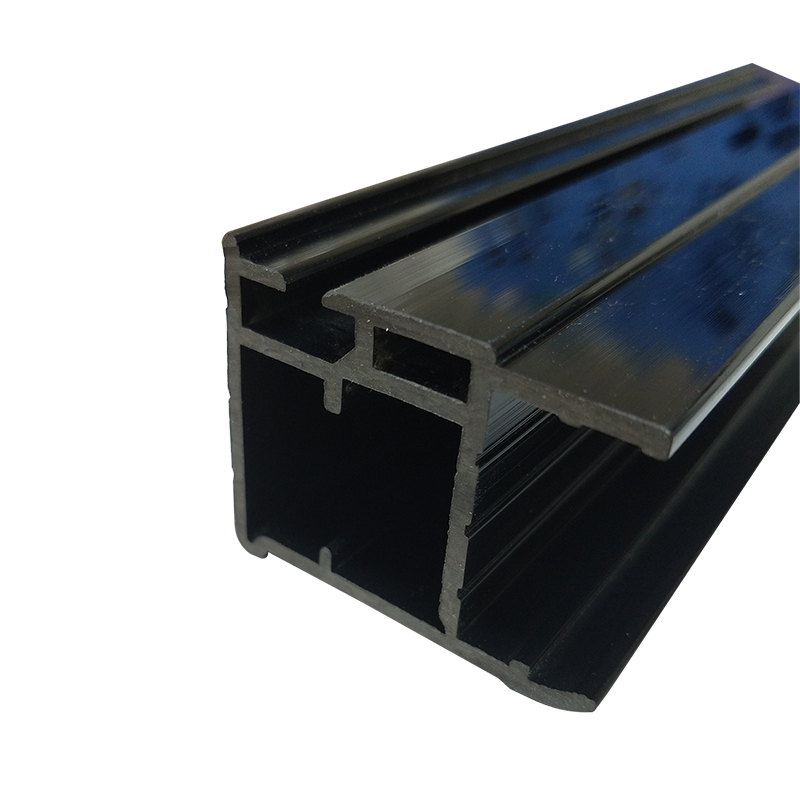

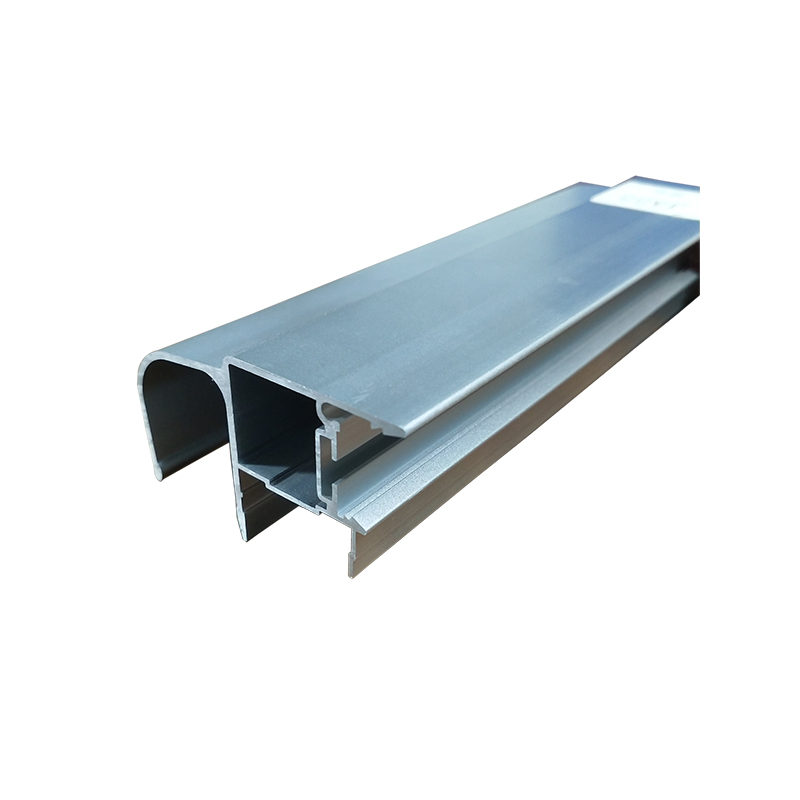

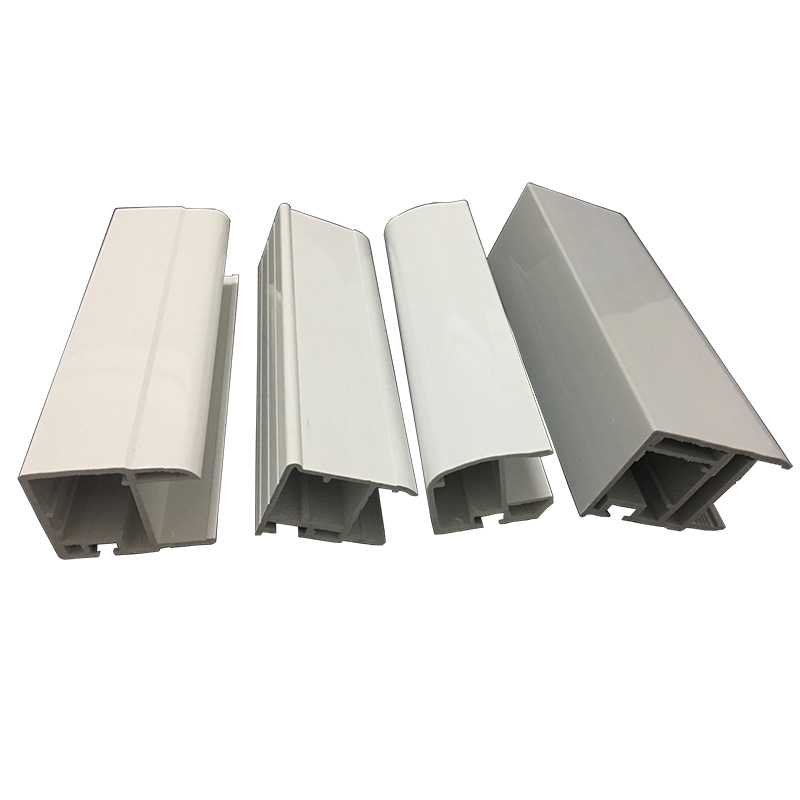

| Specification | PVC Extrusion Profile |

|---|---|

| Material | PVC, ABS, PE |

| Type | Plastic Profiles |

| Thickness | 1.8-2.5MM or as Customer Required |

| Shape | Customized Requirement |

| Color | Silver, White, Brown, Black, Blue, Green, etc. |

Product Manufacturing Process

The manufacturing process of freezer extrusion parts involves several key steps to ensure strength and consistency. Initially, the raw materials are precisely formulated and fed into the extrusion chamber. The chamber maintains a controlled temperature to keep the mixture semi-solid, which is crucial for the desired texture. A screw or auger then propels the mixture through a die, determining the product's final shape. This process not only ensures uniformity but also supports high-volume production. Continued advancements in extrusion technology allow manufacturers to innovate and improve the efficiency of this process further, meeting evolving market demands.

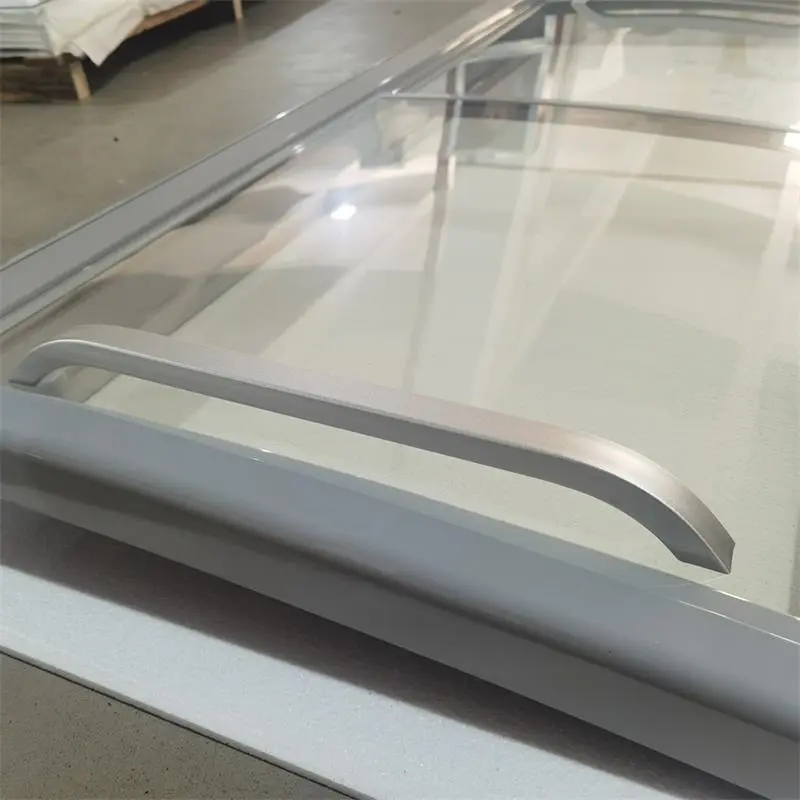

Product Application Scenarios

Freezer extrusion parts like PVC profiles are widely used in various applications due to their durability and flexibility. In the construction industry, they are employed in creating structural components for doors and windows, benefiting from their high resistance to temperature changes and environmental factors. In the food industry, these profiles aid in creating containers and structures for frozen food storage, offering a consistent quality product. Moreover, their application in household and commercial appliances underscores their versatility, providing reliable solutions for diverse scenarios efficiently.

Product After-Sales Service

- Free spare parts available within the warranty period.

- One-year warranty for all extrusion profile products.

- Responsive customer support team to handle queries.

Product Transportation

- Well-packaged using EPE foam and seaworthy wooden cases.

- Ensures secure and damage-free delivery worldwide.

Product Advantages

- High strength with excellent corrosion resistance.

- Eco-friendly materials and manufacturing process.

- Customizable to meet varied specifications and needs.

Product FAQ

- What are freezer extrusion parts? Freezer extrusion parts refer to components manufactured through the extrusion process, primarily used in producing and shaping products like PVC profiles under controlled temperatures.

- Why choose PVC for extrusion parts? PVC offers durability, versatility, and resistance to extreme temperatures, making it an ideal choice for manufacturing extrusion parts for freezer applications.

- How do temperature variations affect the extrusion process? Maintaining precise temperatures is critical, ensuring the mixture remains semi-solid for consistent shaping without premature freezing.

- What are the main applications of these profiles? These profiles are widely used in construction, refrigeration appliances, and food storage solutions due to their durability and adaptability.

- Can these profiles be customized? Yes, customization options are available to meet specific customer requirements for shape, size, and color.

- How is the quality of these products ensured? Rigorous quality checks, including thermal and pressure testing, ensure that each product meets high standards.

- What materials are used in the production? The profiles are produced using high-grade PVC, ABS, and PE materials, ensuring robust performance.

- What is the production capacity? The facility can produce over 250,000m2 of insulated glass and 2000 tons of plastic extrusion profiles annually.

- Who are the primary customers? Our products serve key clients in sectors such as construction, food processing, and retail, including notable brands like Haier and Carrier.

- How are these products shipped? Products are carefully packed in seaworthy wooden cases to ensure safe and secure delivery globally.

Product Hot Topics

- The Rise of Energy-Efficient Extrusion Parts As manufacturers focus on sustainability, energy-efficient extrusion parts have become a hot topic. These parts, crucial for freezer production, help reduce energy consumption while maintaining high performance. By employing advanced materials and precise engineering, manufacturers aim to lower operational costs without compromising quality.

- Innovations in Customizable PVC Profiles Customization is at the forefront of the extrusion industry, with manufacturers offering tailored PVC profiles. This flexibility allows clients to specify dimensions, colors, and features suitable for their unique applications. Such innovations are driving demand across multiple sectors, enhancing both practicality and aesthetics.

- Challenges in Maintaining Temperature Control For manufacturers, the art of freezer extrusion lies in meticulous temperature regulation. This challenge ensures the semi-solid state vital for shaping. Adapting to ingredients' varied responses while maintaining precise environmental conditions is a focal point for ongoing technological advancement.

- Sustainability in Material Choices With environmental concerns escalating, the choice of materials for extrusion parts is pivotal. Manufacturers increasingly focus on eco-friendly options, such as recyclable PVC, to minimize the ecological footprint. This shift not only aligns with global sustainability goals but also appeals to environmentally conscious consumers.

- Enhancing Durability Through Engineering Advances in engineering have significantly boosted the durability of freezer extrusion parts. By employing robust materials and optimizing design parameters, manufacturers deliver products that withstand extreme conditions, ensuring longevity and reliability in demanding environments.

- Exploring New Applications The adaptability of PVC profiles in freezer extrusion extends beyond traditional applications. Manufacturers are exploring new avenues, including innovative uses in modern architecture and design, showcasing the material's versatility and expanding its market reach.

- Quality Assurance Practices A cornerstone for manufacturers, rigorous quality assurance practices ensure that extrusion parts meet stringent standards. Regular testing, including durability and pressure resistance assessments, fortifies customer trust and upholds product excellence.

- Technology's Role in Production Efficiency Technological advancements play a crucial role in enhancing production efficiency for manufacturers. Automation and precision machinery streamline the extrusion process, reducing time and resource wastage while maintaining high-quality outputs.

- Meeting Global Demand As the global market for freezer extrusion parts expands, manufacturers are adapting to meet diverse demands. By expanding production capacities and enhancing logistic capabilities, they cater to international clients, ensuring timely delivery and competitive pricing.

- Leveraging Partnerships for Innovation Collaborations with industry leaders foster innovation in extrusion part manufacturing. By sharing resources and expertise, manufacturers develop cutting-edge solutions, driving the industry forward and setting benchmarks for quality and performance.

Image Description