Product Main Parameters

| Parameter | Details |

|---|---|

| Glass Type | Tempered, Low-E, Heating |

| Glazing | Double, Triple |

| Thickness | 3.2/4mm glass 12A 3.2/4mm glass |

| Size | Max. 2440mm x 3660mm, Min. 350mm*180mm |

| Temperature | -30℃-10℃ |

Common Product Specifications

| Specification | Details |

|---|---|

| Color | Clear, Ultra Clear, Gray, Green, Blue |

| Spacer | Mill finish aluminum |

| Seal | Polysulfide & Butyl Sealant |

| Service | OEM, ODM |

| Warranty | 1 Year |

Product Manufacturing Process

Manufacturers of freezer insulated glass employ a sophisticated process to ensure high-quality, durable products. The process begins with precision glass cutting, followed by edge polishing to ensure smoothness and safety. Drilling and notching add functionality specific to commercial refrigeration needs. A cleaning phase removes any impurities before silk printing adds customized designs. The glass is then tempered to enhance its durability and safety features. A hollow space is created between the glass layers, which may be filled with inert gases like argon or krypton for superior insulation. Finally, PVC extrusion and frame assembly complete the product, which undergoes rigorous quality checks to ensure compliance with industry standards.

Product Application Scenarios

Freezer insulated glass is integral in a variety of commercial and industrial settings. In supermarkets, it is used to enclose refrigerated display cases, allowing customers to view products while minimizing temperature fluctuations. Cold storage facilities utilize these glass units to maintain distinct temperature zones necessary for different perishable goods. Labs and medical facilities use them in specialized cold units for preserving sensitive materials. The strong insulating properties, combined with visibility and durability, make it ideal for any scenario where maintaining a precise, controlled temperature is essential.

Product After-Sales Service

Manufacturers provide comprehensive after-sales service, including free spare parts and a one-year warranty. Technical support is available to assist with installation and troubleshooting, ensuring optimal product performance and customer satisfaction.

Product Transportation

The product is securely packaged using EPE foam and seaworthy wooden cases to prevent damage during transportation. This ensures that the product arrives in pristine condition, ready for installation and use.

Product Advantages

- Energy Efficiency: Reduces energy costs with superior insulation.

- Transparency: High visual light transmittance enhances customer experience.

- Durability: Explosion-proof and anti-frost features ensure longevity.

Product FAQ

- What is the main advantage of using freezer insulated glass? Manufacturers design freezer insulated glass to minimize heat transfer, improving energy efficiency and reducing operational costs.

- Can the glass be customized? Yes, manufacturers offer customized sizes, shapes, and colors to meet specific needs of different commercial applications.

- What gases are used in the insulated space? Manufacturers often use argon or krypton due to their low thermal conductivity, enhancing insulation performance.

- Are there specific maintenance requirements? Regular cleaning is recommended, but the robust construction requires minimal maintenance.

- How does the glass prevent condensation? The insulative properties of the gas-filled spacer and Low-E coatings help prevent moisture build-up and condensation.

- What is the lifespan of freezer insulated glass? With proper maintenance, manufacturers design the glass to last for many years in demanding commercial environments.

- Is the glass environmentally friendly? Yes, manufacturers are increasingly using sustainable materials and processes.

- How is the glass shipped? It is carefully packaged in wooden cases to prevent damage during transportation, ensuring it arrives ready for use.

- What are the warranty terms? Manufacturers provide a one-year warranty with options for extended coverage.

- What industries benefit most from freezer insulated glass? It is beneficial for supermarkets, cold storage, laboratories, and any sector requiring controlled temperature environments.

Product Hot Topics

- Innovations in Freezer Insulated Glass Technologies Manufacturers are exploring smart glass technologies that adjust opacity based on temperature and light, offering enhanced energy efficiency and user experience.

- Eco-Friendly Manufacturing Processes Increasingly, manufacturers are adopting sustainable practices in the production of insulated glass to reduce environmental impact.

- Future Trends in Freezer Insulated Glass The developments in coating technologies continue to improve insulation performance, making freezer insulated glass an even more attractive option for commercial settings.

- The Importance of Quality Control Manufacturers prioritize rigorous quality checks, ensuring that each piece of insulated glass meets high standards for durability and performance.

- Customization in Freezer Insulated Glass Products Manufacturers offer extensive customization options, allowing businesses to tailor glass specifications to their specific needs.

- Global Market Demand As energy costs rise, more businesses globally are turning to manufacturers for energy-efficient freezer insulated glass solutions.

- Understanding the Insulation Properties Exploring the science behind argon and krypton gas fillings and their impact on thermal efficiency in insulated glass.

- Benefits of Low-E Coatings A dive into how manufacturers use Low-E coatings to reflect infrared radiation, thus enhancing the insulation capabilities of freezer glass.

- The Role of Manufacturers in Advancing Technology An analysis of how manufacturers are leading the way in developing more advanced, sustainable freezer insulated glass products.

- Case Studies: Successful Implementation Real-world examples of businesses achieving cost savings and improved efficiency through the use of advanced freezer insulated glass.

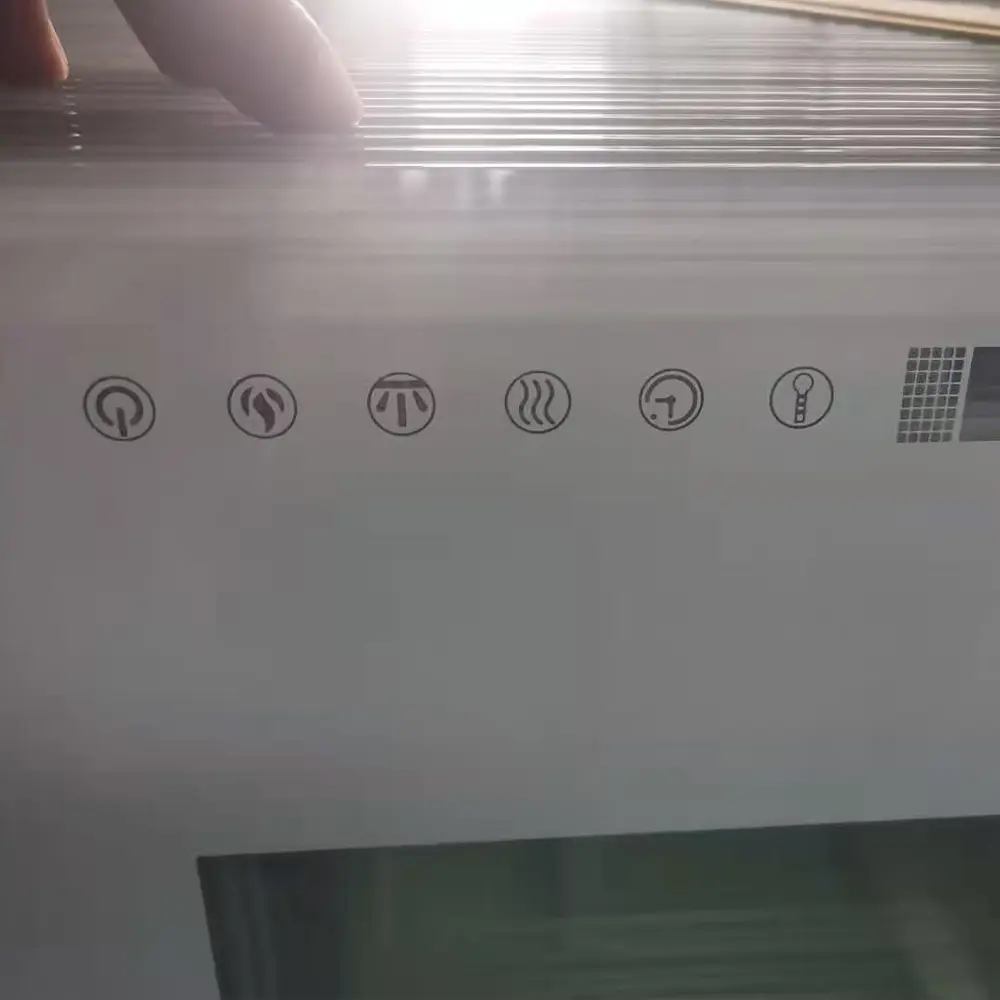

Image Description

There is no picture description for this product