Product Main Parameters

| Product Name | Island Fridge Chest Freezer Aluminum Plastic Frame Sliding Glass Door |

|---|---|

| Glass | 4MM Tempered Low-E Glass |

| Frame | Width: ABS Injection, Length: Aluminum Alloy |

| Glass Thickness | 4mm |

| Size | Width: 660mm, Length: Customized |

| Shape | Curved |

| Color | Black, custom options available |

| Temperature | -25℃ to 10℃ |

| Application | Chest Freezer, Island Freezer, Ice Cream Freezer |

| Accessories | Sealing Strip, Key Lock |

| Door Qty. | 2 pcs sliding glass door |

| Package | EPE Foam Seaworthy Wooden Case (Plywood Carton) |

Common Product Specifications

| Warranty | 1 Year |

|---|---|

| Brand | YB |

| Service | OEM, ODM |

| Features | Anti-fog, Anti-condensation, Anti-frost |

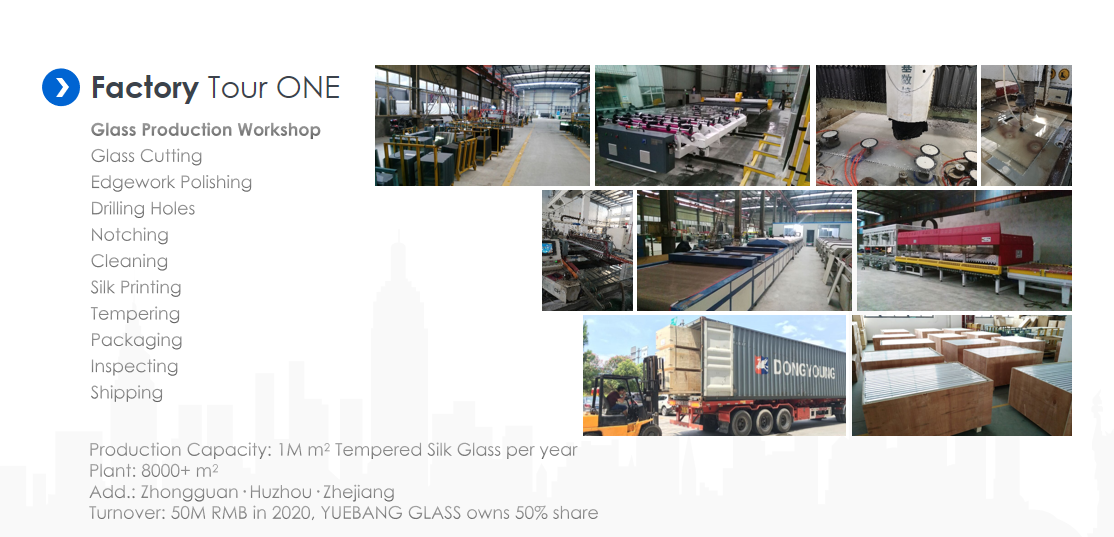

Product Manufacturing Process

Freezer glass door manufacturers utilize advanced production techniques to ensure high-quality output. The process initiates with precision glass cutting followed by edge polishing to create a smooth finish. Holes are then drilled, and any necessary notching is performed. Cleaning precedes the application of silk printing for aesthetic branding. Following this, the glass is tempered to enhance strength and durability. Insulating glass is produced by sealing panes with inert gas, improving thermal efficiency. PVC extrusion is performed to form the customizable frames, which are assembled with the glass and subjected to rigorous quality inspections for integrity. This meticulous process helps manufacturers of cooler glass doors provide reliable and efficient products tailored to varied consumer needs.

Product Application Scenarios

Cooler glass door manufacturers design doors for diverse applications across multiple industries. In retail, supermarkets, and convenience stores, these doors enhance product visibility while maintaining optimal cooling, thus contributing to energy savings. In hospitality, restaurants and cafes utilize them for both customer-facing displays and behind-the-scenes storage. Their versatility extends to residential environments where they are employed in wine coolers and mini refrigerators, offering aesthetic appeal and efficient cooling. Research indicates that using glass doors with advanced insulation can significantly reduce energy consumption in refrigeration systems, aligning with global sustainability efforts.

Product After-sales Service

Manufacturers provide a one-year warranty covering defects and offer free spare parts for repairs within this period. They deliver OEM and ODM services, ensuring products meet unique customer specifications. Skilled technical support and service teams are available for troubleshooting and maintenance advice.

Product Transportation

Cooler glass doors are carefully packed in EPE foam and sealed within seaworthy wooden cases to prevent damage during transit. The commitment to quality extends beyond manufacturing, ensuring products reach customers securely and intact, reflecting manufacturers' emphasis on reliability.

Product Advantages

- Energy Efficiency: Minimizes heat transfer and maintains cooler temperature.

- Durability: Made with tempered Low-E glass and corrosion-resistant frames.

- Customizable Design: Frames and sizes tailored to customer needs.

- Aesthetic Appeal: Enhances product visibility with anti-fogging technology.

Product FAQ

- Q: Are you a manufacturer or trading company?

A: We are manufacturers specializing in cooler glass doors, inviting you to tour our facility. - Q: What is the MOQ?

A: MOQ varies per design. Send us your design specifications and we will provide details. - Q: Can I use my logo?

A: Yes, we offer customization, including logo placement, to meet brand requirements. - Q: Are customized products possible?

A: Absolutely, we adapt to your specifications for glass thickness, color, and more. - Q: What is the warranty?

A: We provide a one-year warranty against manufacturing defects. - Q: What are the payment terms?

A: Payments can be made via T/T, L/C, Western Union, or other agreed terms. - Q: How long is the lead time?

A: If stock is available, around 7 days; otherwise, 20-35 days post-deposit for custom orders. - Q: Can you offer me the best price?

A: Pricing depends on order volume. Contact us with details for a bespoke quote. - Q: How do you ensure product quality?

A: Our dedication to quality is supported by a special inspection laboratory and continuous improvement processes. - Q: How is the product packaged for delivery?

A: Products are safely encased in EPE foam and plywood cartons for secure global shipping.

Product Hot Topics

- Energy Efficiency in Retail: A Focus on Cooler Glass Doors

Energy efficiency in retail environments is a growing concern, and manufacturers of cooler glass doors are addressing this through innovative designs. By minimizing heat exchange and incorporating anti-fog technologies, these doors enhance visibility while reducing energy consumption. This not only supports environmental goals but also decreases operational costs for retailers. Reliable manufacturers prioritize sustainability, making cooler glass doors an attractive solution for energy-conscious businesses. - Customization Trends in Cooler Glass Doors

Manufacturers are increasingly offering customized cooler glass doors to meet diverse market demands. Consumers seek personalized solutions that match their specific needs, from logo integration to bespoke dimensions and frame colors. This trend reflects businesses' growing awareness that customization can enhance brand identity and optimize space utilization. Manufacturers dedicated to flexibility and innovation are well-positioned to capitalize on this customization trend. - The Role of Cooler Glass Doors in Food Safety

Maintaining proper temperature in refrigerators and freezers is crucial for food safety, and cooler glass doors play an instrumental role. Featuring advanced insulation methods, these doors help stabilize internal temperatures, ensuring perishable goods remain fresh. For foodservice industries, investing in high-quality cooler glass doors from reputable manufacturers is a decisive step towards regulatory compliance and customer satisfaction. - Innovations in Anti-fog Technology for Cooler Glass Doors

Anti-fog technology is essential for cooler glass doors to ensure product visibility in high-humidity environments. Recent advancements by leading manufacturers include heated frames and special coatings that prevent condensation. These innovations provide clear views into refrigerators, enhancing the consumer experience and allowing efficient stock management without frequent door opening. - Impact of Cooler Glass Doors on Brand Aesthetics

Cooler glass doors offer a unique intersection of functionality and aesthetic appeal, greatly impacting brand presentation. The ability to view products through stylish, clear glass doors invites customer engagement and enhances the perceived value of displayed items. Businesses partnering with manufacturers that offer customizable designs can differentiate themselves through distinct, visually appealing refrigeration solutions. - Global Supply Chains and Cooler Glass Door Production

Understanding the global supply chain dynamics is crucial for manufacturers of cooler glass doors. Changes in raw material availability, shipping routes, and tariffs can affect production timelines and costs. Manufacturers who proactively manage their supply chains and foster strong partnerships are better equipped to maintain product consistency and competitive pricing, even during disruptions. - Advancements in Glass Door Security Features

Security is paramount in retail settings, and manufacturers are integrating innovative locking mechanisms in cooler glass doors. These features prevent unauthorized access, safeguarding valuable merchandise. As theft prevention becomes crucial, manufacturers offering robust security solutions are essential partners for retailers seeking to protect their investments while providing seamless customer access. - Importance of Routine Maintenance for Cooler Glass Doors

Regular maintenance of cooler glass doors is vital for optimal functioning and longevity. Manufacturers provide guidelines for routine checks, such as seal integrity and hinge adjustments. Adhering to these recommendations ensures that doors maintain their energy efficiency and operate smoothly, protecting the initial investment and reducing the need for costly replacements. - Cooler Glass Doors in the Global Market: Trends and Predictions

The demand for cooler glass doors is escalating as markets prioritize energy efficiency, aesthetics, and sustainability. Manufacturers are adapting to these demands by investing in innovative production technologies and materials. The global adoption of stringent energy regulations will likely drive further growth in this sector, making manufacturers of high-quality, compliant products key players in the market. - The Integration of Smart Technology in Cooler Glass Doors

Smart technology integration is an emerging trend among manufacturers of cooler glass doors. Features like automated temperature adjustments and remote monitoring capabilities are becoming more prevalent, offering enhanced functionality and efficiency. This technology empowers businesses to optimize refrigeration performance and energy use, aligning with the digital transformation sweeping across industries.

Image Description