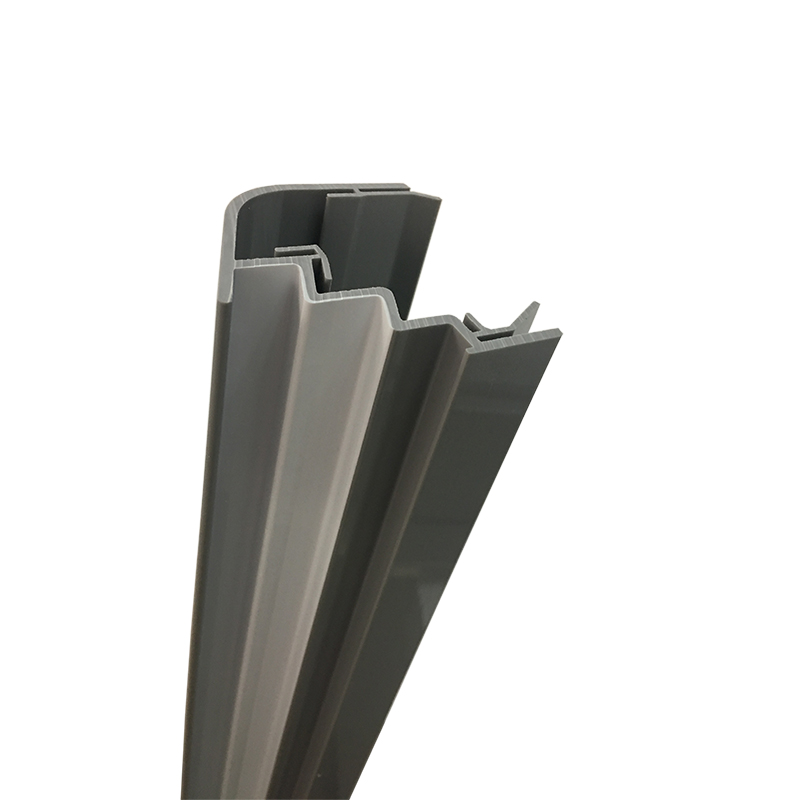

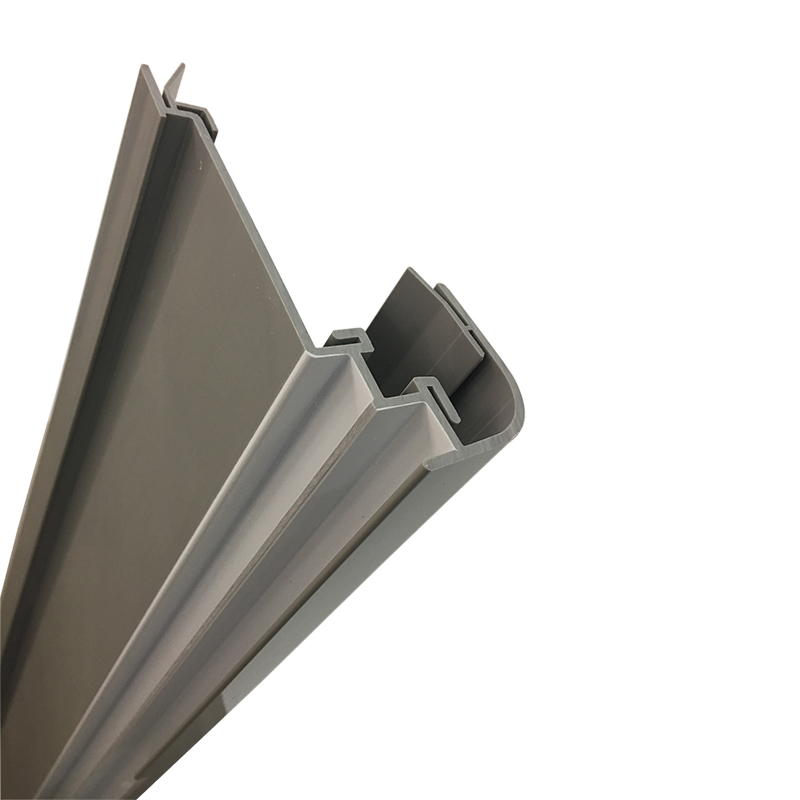

Product Main Parameters

| Specification | Details |

|---|---|

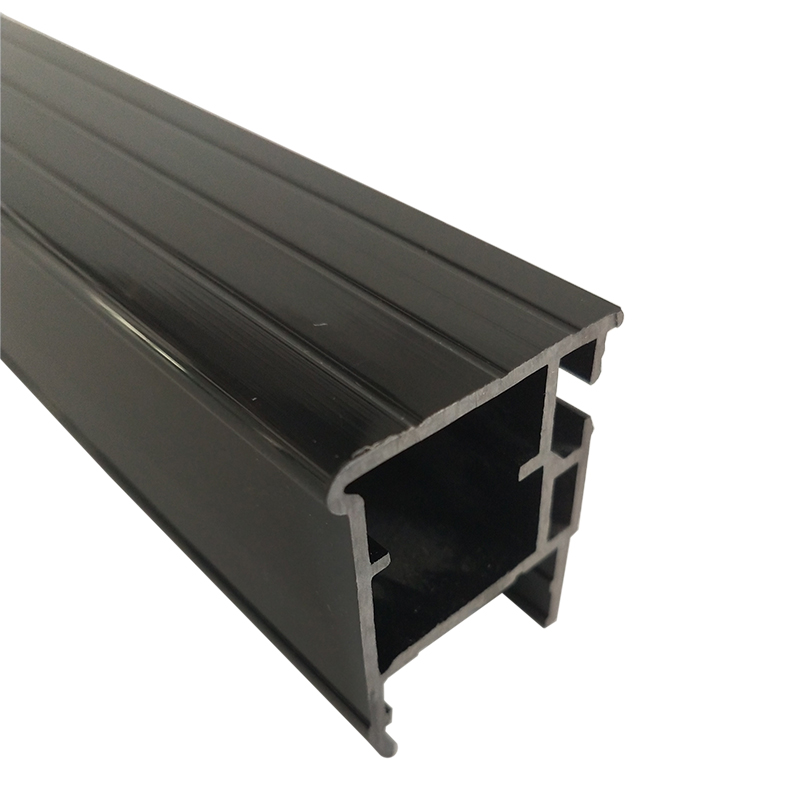

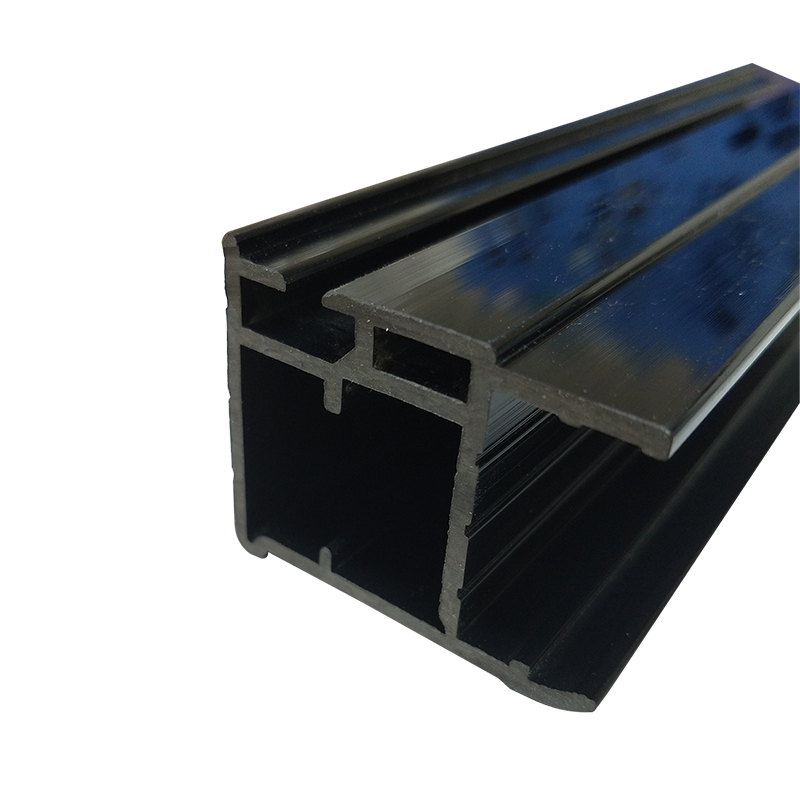

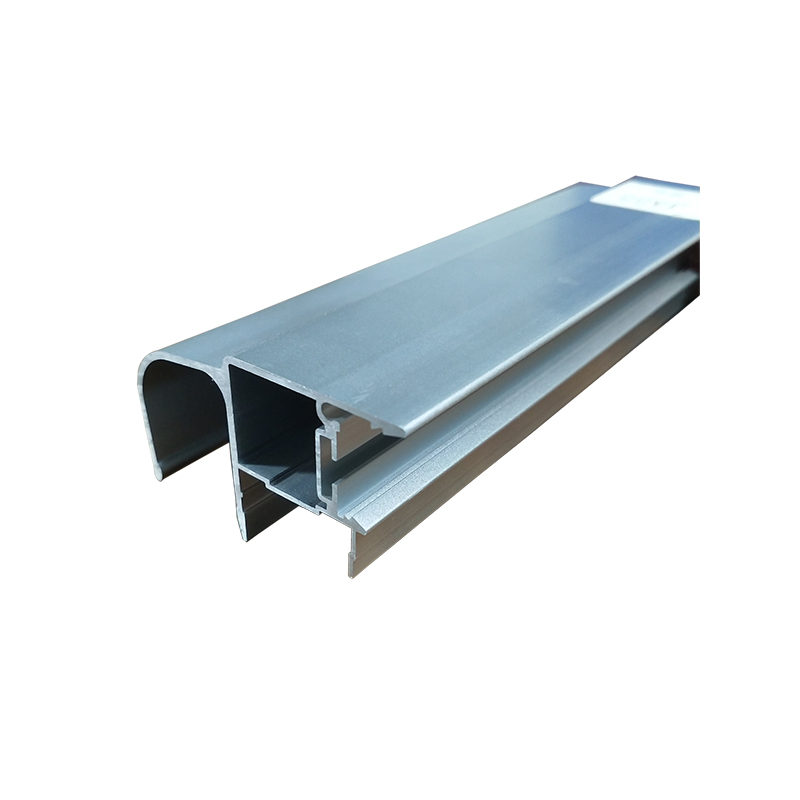

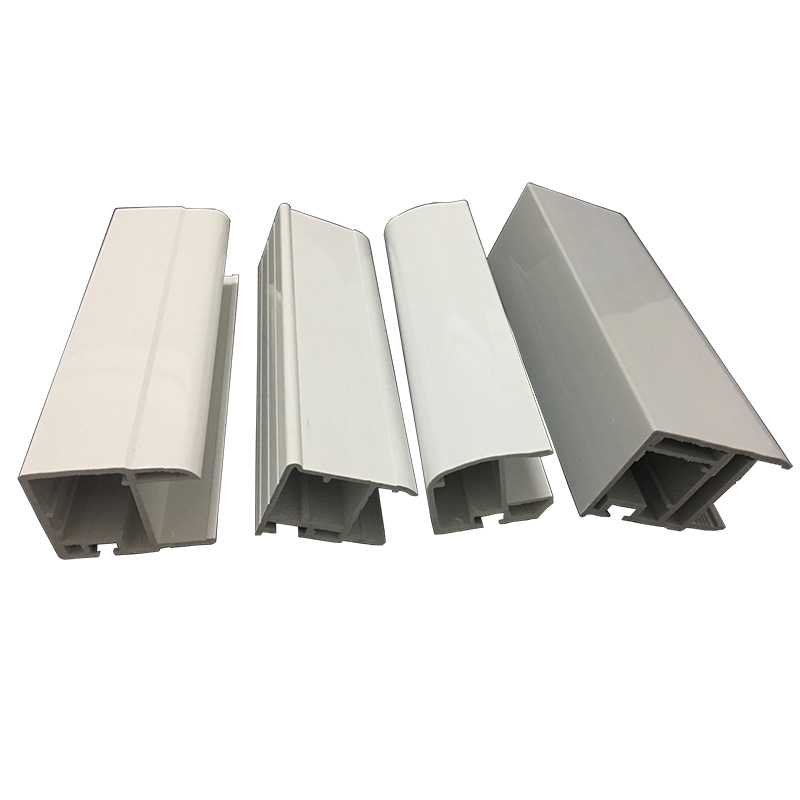

| Material | PVC, ABS, PE |

| Type | Plastic Profiles |

| Thickness | 1.8-2.5MM or as Customer Required |

| Shape | Customized Requirement |

| Color | Silver, White, Brown, Black, Blue, Green, etc. |

| Usage | Construction, Building Profile, Refrigerator Door, Window, etc. |

| Application | Hotel, House, Apartment, Office Building, School, Supermarket, etc. |

| Package | EPE foam Seaworthy wooden case (Plywood Carton) |

| Service | OEM, ODM, etc. |

| After-sales Service | Free Spare Parts |

| Warranty | 1 Year |

| Brand | YB |

Common Product Specifications

| Feature | Description |

|---|---|

| High strength | Corrosion resistance and anti-aging performance |

| Space saving | Easy operating, easy to install and clean |

| Processing stability | Strong processing stability and good fluidity |

| Temperature resistance | High and low temperature resistance |

| Environmentally friendly | Material is environmentally friendly |

Product Manufacturing Process

According to recent authoritative papers on the manufacturing of plastic profiles, the extrusion process stands out due to its efficiency and precision. The process involves forcing heated plastic material through a die to form continuous profiles, making it ideal for long, uniform products. Key stages include plasticizing the material, shaping it through the die, cooling, and cutting into desired lengths. The accuracy of this method ensures high-quality profiles that meet diverse specifications. With advancements in technology, manufacturers can achieve greater consistency, reduced waste, and enhanced customization options.

Product Application Scenarios

Plastic extrusion profiles are critical in refrigeration and cooler systems due to their formability and thermal properties. As per recent studies, these profiles efficiently serve in door seals, gaskets, and structural components, essential for maintaining airtight closures and optimizing thermal regulation. The versatility in design allows manufacturers to tailor profiles for specific aesthetic and functional needs, enhancing overall system performance. Additionally, their lightweight nature facilitates easy handling, installation, and transportation, making them a preferred choice in both commercial and residential refrigeration solutions.

Product After-sales Service

- Free Spare Parts: Rapid replacement for any defective part within the warranty period.

- 24/7 Support: Available for troubleshooting and assistance.

- Custom Solutions: Tailored support for unique application challenges.

Product Transportation

- Secure Packaging: Packed with EPE foam and seaworthy wooden cases to ensure safe delivery.

- Global Shipping: Efficient logistics to ensure timely delivery across continents.

- Tracking: Real-time tracking of shipments for transparency and coordination.

Product Advantages

- Cost Efficiency: Affordable alternative to metal components.

- Versatility: Customizable for various cooling system designs.

- Lightweight and Durable: Reduces cooler weight while extending lifespan.

- Corrosion Resistance: Ideal for moist environments in coolers.

Product FAQ

- What materials are used in your profiles? We use PVC, ABS, and PE for our plastic extrusion profiles, providing strength, durability, and adaptability for cooler applications.

- Can these profiles be customized? Yes, as leading manufacturers, we offer complete customization of our plastic extrusion profile for cooler systems to meet specific client requirements.

- How do these profiles improve cooler efficiency? Our profiles enhance airtight sealing, thermal insulation, and structural support, thereby boosting energy efficiency in cooler systems.

- What is the typical lifespan of these profiles? Our profiles, due to their high-quality materials and construction, have a long lifespan and are resistant to aging and corrosion.

- Are these profiles environmentally friendly? Yes, our profiles are made with eco-friendly materials and processes, ensuring sustainability throughout their lifecycle.

- Do you offer OEM services? Yes, we provide OEM services, allowing businesses to integrate our profiles seamlessly into their products with custom branding.

- How resistant are these profiles to temperature variations? Our profiles are tested to withstand extreme temperature ranges, making them ideal for both cold and hot environments in refrigeration.

- What after-sales services do you offer? We offer free spare parts and 24/7 support to assist with any issues post-purchase.

- How are products packaged and shipped? Products are securely packaged with EPE foam and seaworthy wooden cases, with global shipping options available to ensure safe and timely delivery.

- What makes your profiles stand out from competitors? Our combination of customization, high-quality materials, and advanced manufacturing processes ensure our profiles provide unmatched performance and value.

Product Hot Topics

- Customizable Designs for Diverse Applications Manufacturers of plastic extrusion profiles for cooler systems cater to diverse market needs by offering customizable solutions. This adaptability allows businesses to enhance their cooling products' effectiveness and appeal.

- Advancements in Plastic Extrusion Technology Recent innovations in extrusion technology have enabled manufacturers to boost production efficiency while maintaining high-quality output. These advancements are crucial in meeting increasing demand in the refrigeration industry.

- The Environmental Impact of Plastic Profiles As sustainability becomes a top priority, manufacturers focus on eco-friendly materials and processes for their plastic extrusion profiles. This shift not only benefits the environment but also aligns with consumer preferences for green products.

- Energy Efficiency in Cooler Systems The integration of plastic extrusion profiles significantly enhances the energy efficiency of cooler systems. By ensuring optimal sealing and insulation, these profiles reduce energy consumption, benefiting both consumers and the environment.

- Cost-Effectiveness of Plastic Profiles vs. Metal When comparing costs, manufacturers find that plastic extrusion profiles offer a cost-effective alternative to metal components without compromising on performance or durability in cooler applications.

- Product Innovation in Cooler Accessories To stay competitive, manufacturers continuously innovate with their plastic extrusion profiles, introducing new designs and materials that offer superior performance in cooler systems.

- Global Market Trends in Refrigeration Components As demand for refrigeration solutions grows worldwide, manufacturers of plastic extrusion profiles for coolers capitalize on emerging markets by adapting to local preferences and regulations.

- Maintaining Standards with Quality Control Leading manufacturers implement strict quality control measures for their plastic extrusion profiles to ensure consistency and reliability, maintaining their reputation in the global market.

- The Role of Plastic Profiles in Modern Refrigeration Plastic extrusion profiles play a vital role in revolutionizing refrigeration technology by providing lightweight, durable, and aesthetically pleasing solutions for modern cooling systems.

- Challenges in the Plastic Extrusion Industry Despite its growth, manufacturers face challenges such as rising raw material costs and environmental regulations. Addressing these through innovation and adaptation remains key to sustaining industry success.

Image Description