Product Main Parameters

| Parameter | Specification |

|---|---|

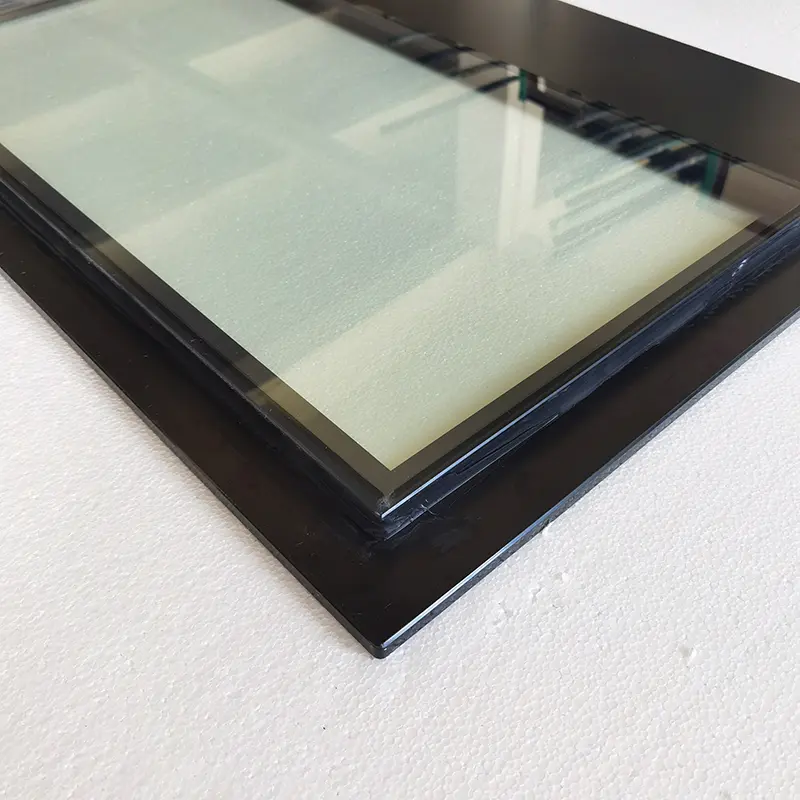

| Glass Type | Tempered, Low-E |

| Insulation | Double Glazing, Triple Glazing |

| Gas Insert | Air, Argon; Krypton is optional |

| Glass Thickness | 8mm glass 12A 4mm glass, 12mm glass 12A 4mm glass |

| Temperature Range | 0℃-22℃ |

Common Product Specifications

| Feature | Description |

|---|---|

| Anti-Fog | Reduces visibility issues |

| Explosion-Proof | High resistance to impact |

| UV Resistance | Low-E coating for UV protection |

| Handle Options | Recessed, Add-on, Full Long, Customized |

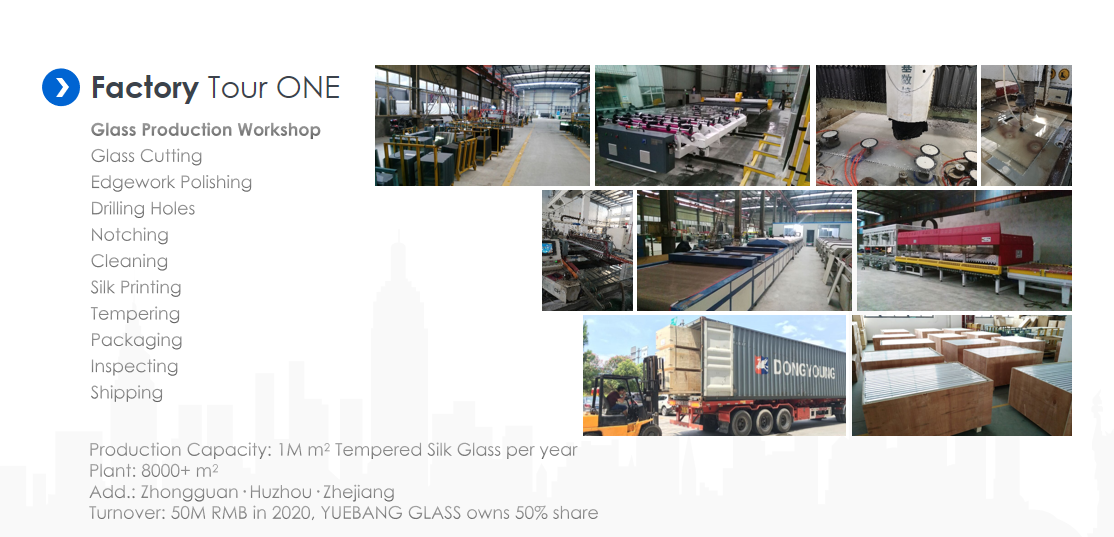

Product Manufacturing Process

The production of Vacuum Insulated Glass Doors involves advanced engineering to ensure optimal thermal performance and durability. The process begins with selecting high-quality raw materials, including tempered and Low-E glass. These materials undergo precision cutting and edge polishing to ensure a flawless surface. The vacuum insulation step is critical, requiring the removal of air between the glass panes to minimize heat transfer. State-of-the-art machines create a precise vacuum gap, reinforced by tiny support pillars to maintain structure. A final sealing process using polysulfide and butyl ensures airtight insulation.

Product Application Scenarios

Vacuum Insulated Glass Doors are increasingly being utilized in both commercial and residential settings. Research indicates that these doors significantly enhance energy efficiency, making them ideal for supermarkets, convenience stores, and residential kitchens. In commercial applications, they contribute to energy cost savings and improved visual merchandising. At home, they offer stylish, functional solutions for modern kitchen designs, ensuring consistent freezer temperatures and reduced condensation.

Product After-Sales Service

- Free Spare Parts for warranty coverage period

- Responsive customer support for troubleshooting and maintenance

Product Transportation

Our products are securely packaged using EPE foam and seaworthy wooden cases (Plywood Carton) to ensure safe transportation. Shipment is available from Shanghai or Ningbo ports, ensuring timely delivery across global markets.

Product Advantages

- Energy Efficiency: Reduces energy costs through superior insulation.

- Temperature Stability: Maintains consistent freezer temperature, preventing freezer burn.

- Condensation Reduction: Minimizes fogging issues for better visibility.

Product FAQ

- Q: What is the primary benefit of Vacuum Insulated Glass Doors from manufacturers? A: Manufacturers offer VIG technology that provides superior thermal insulation, significantly reducing energy consumption and maintaining consistent internal temperatures.

- Q: How does vacuum insulation improve energy efficiency? A: By removing air and creating a vacuum between glass panes, manufacturers significantly reduce conductive and convective heat losses, enhancing energy efficiency.

Product Hot Topics

Energy Efficiency in Commercial Refrigeration: Manufacturers of Vacuum Insulated Glass Door for freezer have revolutionized the industry by providing doors that significantly cut energy costs. Their advanced insulation technology helps maintain optimal freezer temperatures, making them ideal for supermarkets and other retail outlets.

Innovative Applications in Residential Kitchens: Modern home designs increasingly integrate Vacuum Insulated Glass Door technology, capitalizing on its sleek aesthetic and energy-saving properties. Manufacturers have responded with customizable options to fit diverse design preferences.

Image Description