Product Details

| Feature | Specification |

|---|---|

| Glass Type | Tempered, Low-E |

| Insulation | Double Glazing, Triple Glazing |

| Insert Gas | Air, Argon; Krypton optional |

| Glass Thickness | 8mm glass 12A 4mm glass, 12mm glass 12A 4mm glass |

| Color | Black, Silver, Red, Blue, Green, Gold, Customized |

| Temperature Range | 0℃-22℃ |

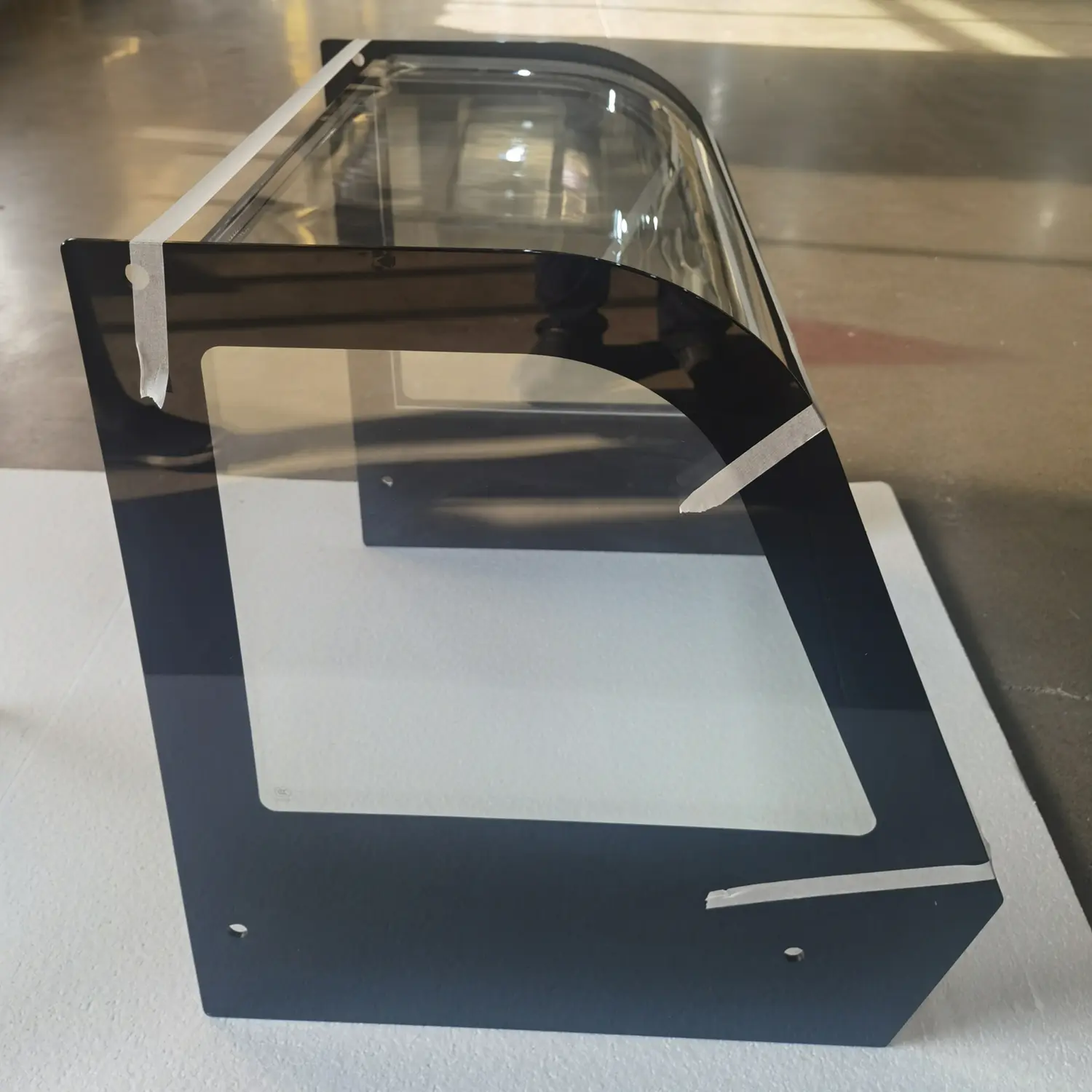

| Application | Display Cabinet, Showcase, etc. |

| Usage Scenario | Bakery, Cake Shop, Supermarket, Fruit Store, etc. |

| Package | EPE foam Seaworthy wooden case (Plywood Carton) |

| Service | OEM, ODM, etc. |

Common Product Specifications

| Material | Details |

|---|---|

| Spacer | Mill finish aluminum filled with desiccant |

| Seal | Polysulfide & Butyl Sealant |

| Warranty | 1 Year |

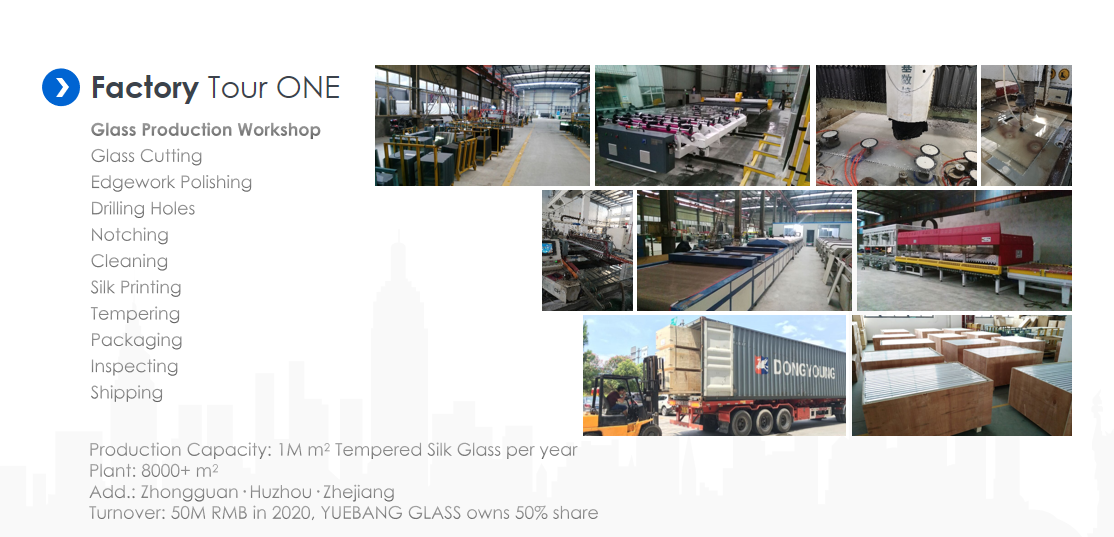

Manufacturing Process

The manufacturing process of beverage cooler insulating glass includes precise glass cutting, tempering, and glazing. Modern methodologies utilize sophisticated machinery to ensure the highest quality. According to recent authoritative papers, the use of Low-E coatings in the glass manufacturing process enhances thermal efficiency significantly, offering better UV resistance and reduced energy costs. The integration of inert gases like argon and krypton between the glass panes boosts insulation properties, thus assuring minimal thermal transfer. Manufacturers employ robust quality control measures to maintain consistency in product performance, aligning with global standards for refrigeration solutions.

Product Application Scenarios

Beverage cooler insulating glass is primarily used in commercial refrigeration units including display cabinets and showcases found in supermarkets, bakeries, and restaurants. Studies suggest that this glass type significantly improves visibility and product appeal while maintaining optimal internal temperatures, crucial for beverage preservation. Manufacturers provide solutions that meet specific commercial needs, such as anti-fog and anti-condensation features that ensure customer satisfaction and reduce maintenance costs. Current market trends emphasize eco-friendly practices, where beverage cooler insulating glass stands out due to its energy-efficient properties.

After-sales Service

Manufacturers of beverage cooler insulating glass offer comprehensive after-sales service, including free spare parts within warranty, and support via multiple communication channels. Each product is covered by a 1-year warranty period.

Product Transportation

Products are securely packed using EPE foam and seaworthy wooden cases, ensuring safe transit to prevent damage. Shipments are facilitated through major ports like Shanghai or Ningbo, optimizing logistics efficiency for global customers.

Product Advantages

- Enhanced thermal insulation reduces energy costs.

- Durable construction ensures long-term reliability.

- Customizable options to fit diverse commercial needs.

- Advanced Low-E coatings for improved UV resistance.

- Anti-fog and anti-condensation features increase product visibility.

Product FAQ

- Are you a manufacturer or trading company? - We are a manufacturer with over 20 years of experience, providing direct factory support and visits.

- What is the MOQ for your products? - The minimum order quantity varies by design. Please contact us with your specific requirements for more details.

- Can I customize the product specifications? - Yes, our products can be customized to meet your specific needs, including glass thickness, size, and color.

- What payment methods do you accept? - We accept T/T, L/C, Western Union, and other terms based on customer preferences.

- How long is the lead time for orders? - For stock items, the lead time is approximately 7 days. Custom orders may require 20-35 days after deposit.

- What warranty is provided? - Our beverage cooler insulating glass products come with a 1-year warranty, ensuring quality and performance assurance.

- Can I use my own logo on the products? - Yes, we offer customization options, including branding with your logo.

- How is the product packaged for shipping? - Our products are packaged using EPE foam and seaworthy wooden cases to ensure safe transportation.

- Do you provide after-sales support? - Comprehensive support is available, including free spare parts within the warranty period and accessible customer service.

- What makes your insulating glass energy-efficient? - The use of Low-E coatings and inert gases like argon improves thermal efficiency, reducing energy consumption significantly.

Product Hot Topics

- How does beverage cooler insulating glass improve energy efficiency? - Manufacturers of beverage cooler insulating glass enhance energy efficiency through advanced technologies like Low-E coatings and the use of inert gases. This specialized glass minimizes thermal transfer, reducing the workload on refrigeration systems, thereby resulting in lower energy consumption and operating costs. These features play a crucial role in commercial settings where energy efficiency translates to significant fiscal savings.

- What are the long-term benefits of using insulating glass for commercial refrigeration? - The long-term advantages of beverage cooler insulating glass include reduced energy costs due to its superior insulation properties and improved visibility with anti-fog features. Manufacturers emphasize the product's durability and reliability, reducing replacement frequency and maintenance hassles, ultimately offering a high return on investment for businesses.

- Why is low-emissivity (Low-E) glass important for beverage coolers? - Low-E glass is critical in beverage coolers for its ability to reflect heat, thereby enhancing thermal insulation. Manufacturers of beverage cooler insulating glass use Low-E coatings to maintain optimal cooling temperatures and prolong the freshness of stored beverages, which is particularly vital in hot climates and high-traffic commercial environments.

- Can beverage cooler insulating glass prevent condensation effectively? - Yes, the design of beverage cooler insulating glass by leading manufacturers includes anti-condensation and anti-fog properties, maintaining clear glass surfaces. This results in better visibility of products, reduced water damage, and an enhanced consumer experience, which is essential for retail and food service industries.

- What customization options are available for insulating glass? - Manufacturers offer extensive customization for beverage cooler insulating glass, including size, shape, color, and thickness adjustments. Businesses can tailor these products to suit specific branding requirements and operational needs, ensuring compatibility with diverse commercial refrigeration units.

- How do manufacturers ensure the durability of insulating glass? - To ensure durability, manufacturers of beverage cooler insulating glass utilize tempered glass and robust sealing techniques. Products are designed to withstand the rigors of commercial use, providing long-lasting performance and reliability under varying conditions.

- What role does glass thickness play in thermal insulation? - The thickness of beverage cooler insulating glass directly influences its thermal properties. Manufacturers optimize glass thickness to balance insulation, durability, and cost-effectiveness, ensuring superior energy efficiency without compromising structural integrity.

- How is the environmental impact minimized for insulating glass? - By reducing energy consumption in refrigeration, manufacturers of beverage cooler insulating glass contribute to lower greenhouse gas emissions. This aligns with environmental sustainability goals, supporting eco-friendly practices in commercial operations.

- Why is insulating glass a popular choice in the food and beverage industry? - The food and beverage industry prefers beverage cooler insulating glass for its energy efficiency, durability, and ability to maintain optimal product temperatures. This glass type supports operational cost savings and enhances product presentation, making it indispensable for businesses prioritizing quality and sustainability.

- What sets your insulating glass apart from competitors? - Our manufacturer's expertise and commitment to innovation in beverage cooler insulating glass lead to cutting-edge solutions tailored for efficiency and longevity. Our extensive customization options, rigorous quality control, and exceptional customer service underscore our leadership in the market.

Image Description