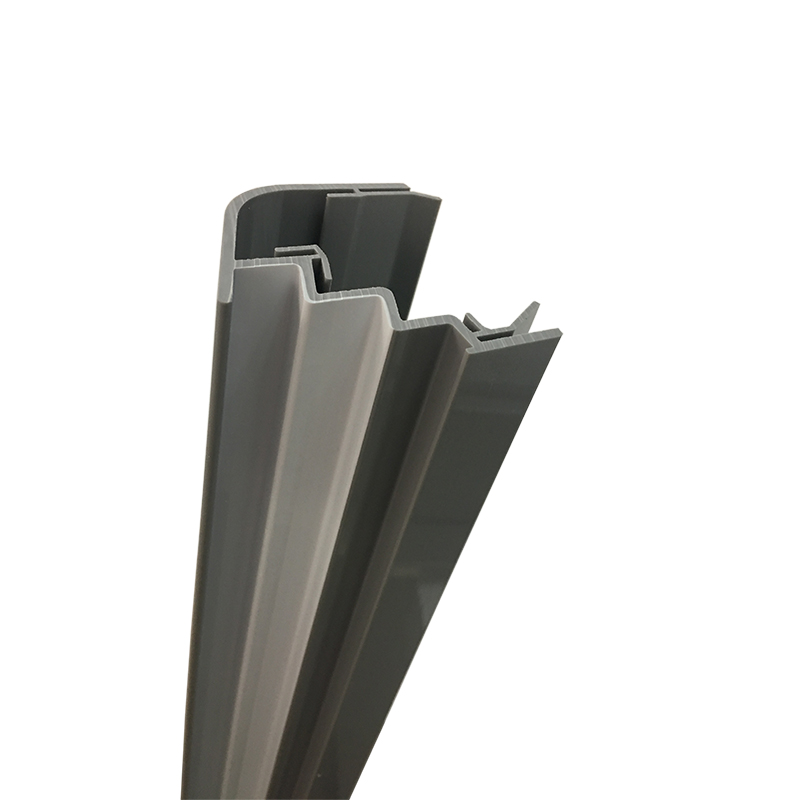

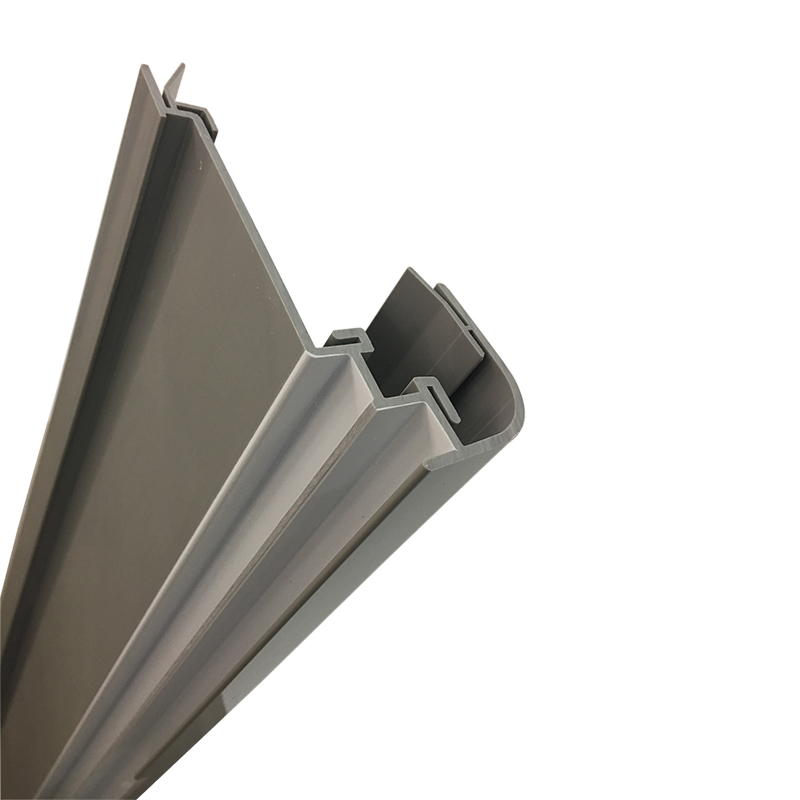

Product Main Parameters

| Parameter | Description |

|---|---|

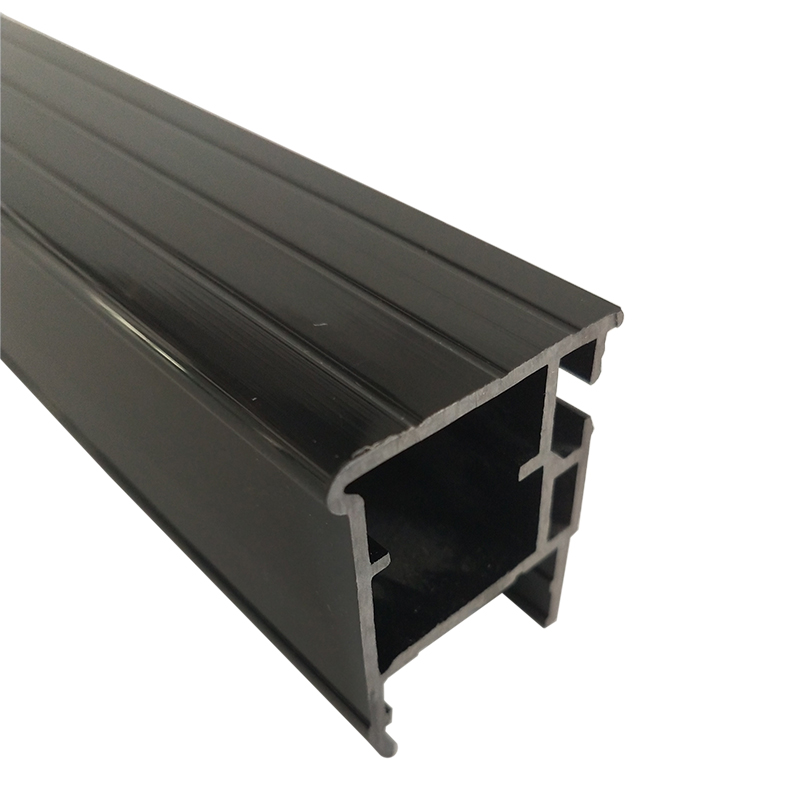

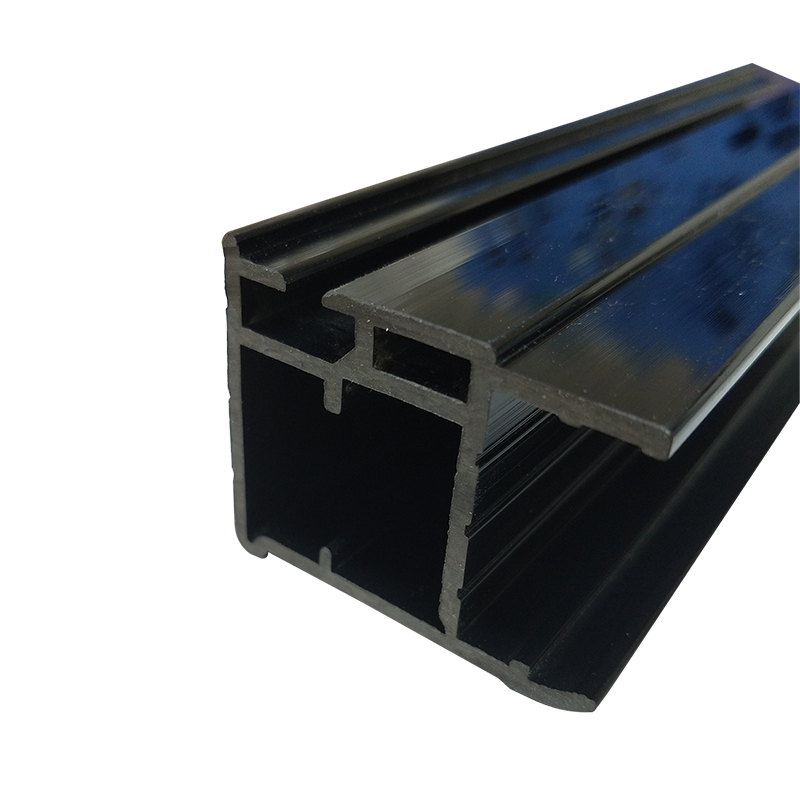

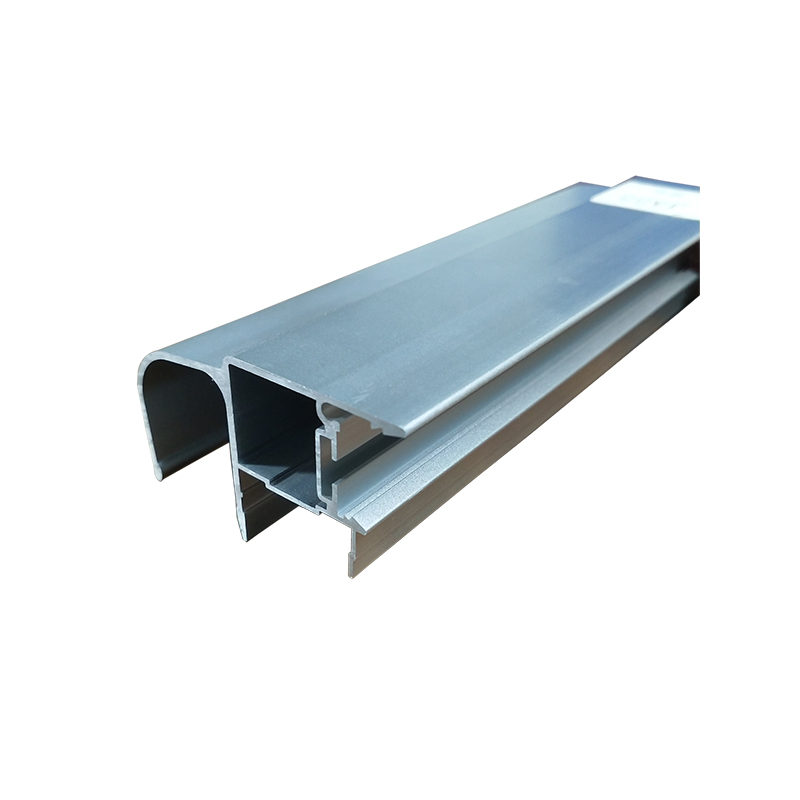

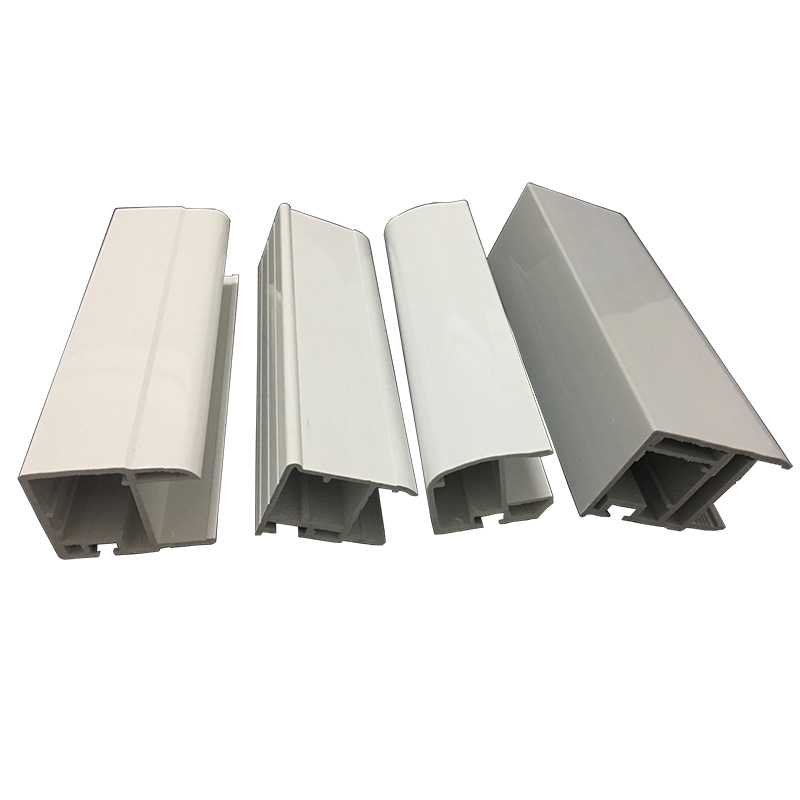

| Material | PVC, ABS, PE |

| Type | Plastic Profiles |

| Thickness | 1.8-2.5MM or as Required |

| Color | Silver, White, Brown, etc. |

Common Product Specifications

| Specification | Description |

|---|---|

| Usage | Construction, Building Profile, etc. |

| Application | Hotel, House, Supermarket, etc. |

| Service | OEM, ODM |

Product Manufacturing Process

The manufacturing of PVC profiles involves several meticulous stages to ensure quality and performance. Initially, raw PVC material is mixed with specific additives to enhance properties such as UV resistance and flexibility. This mixture is then fed into an extrusion machine where it is heated and shaped into the desired profile using custom molds. Consistent temperature and pressure are maintained to achieve uniform extrusion. The extruded profiles are cooled gradually to maintain structural integrity before being cut to specific lengths and shapes. The final product undergoes thorough quality checks, including dimension accuracy and strength tests, ensuring that each profile meets stringent industry standards. This process aligns with current industry best practices, as noted in authoritative research papers, underscoring the efficiency and resilience of extruded PVC profiles for cooler systems.

Product Application Scenarios

PVC profiles are integral to the construction of cooling systems in diverse settings. In residential and commercial applications, they provide structural support for air and evaporative coolers, contributing to their stability and efficiency. Industrial scenarios, such as in large-scale refrigeration and HVAC systems, benefit from PVC's lightweight and durable properties. These profiles facilitate easy assembly and promote efficient airflow management, crucial for maintaining optimal cooling performance. Their resistance to environmental factors makes them suitable for outdoor installations, where they withstand UV exposure and moisture. Research underlines that the adaptability and cost-effectiveness of PVC profiles make them a preferred choice across various cooler systems, enhancing longevity and operational efficiency.

Product After-Sales Service

We offer comprehensive after-sales support for our PVC profiles, including free spare parts and a one-year warranty. Our dedicated team provides prompt assistance to address any product issues, ensuring customer satisfaction and maintaining product performance.

Product Transportation

Our PVC profiles are securely packaged using EPE foam and seaworthy wooden cases to prevent damage during transit. We ensure timely delivery across global locations, leveraging an efficient logistics network.

Product Advantages

- Corrosion Resistance: Ensures longevity even in moisture-rich environments.

- Cost-Effective: Offers a budget-friendly solution without compromising on quality.

- Lightweight: Simplifies installation and transportation.

- Thermal Insulation: Enhances energy efficiency in cooling systems.

- Customizable: Meets specific design and functional requirements.

Product FAQ

- What materials are used in manufacturing the PVC profiles?Our PVC profiles are manufactured using high-quality PVC, ABS, and PE materials, ensuring durability and performance in cooler systems applications. As reputable manufacturers, we prioritize quality raw materials.

- Can the PVC profiles be customized?Yes, we offer customization options for our PVC profiles, including varying thicknesses, colors, and shapes, tailored to specific cooler system requirements. This flexibility caters to diverse manufacturing needs.

- How does PVC profile enhance cooler efficiency?PVC profiles contribute to effective thermal insulation and airflow management in coolers, reducing energy consumption and enhancing overall cooling efficiency. Our focus as manufacturers is on optimizing performance.

- What is the operational temperature range for these profiles?Our PVC profiles for coolers can withstand temperatures from -40℃ to 80℃, ensuring reliability and performance under varying environmental conditions.

- Are these PVC profiles environmentally friendly?Yes, our PVC profiles are eco-friendly, manufactured with sustainable practices, and designed to minimize environmental impact while ensuring optimal performance.

- Do the profiles require special maintenance?No, our PVC profiles are designed for minimal maintenance, boasting properties like corrosion resistance and UV stability, making them a hassle-free choice for cooler systems.

- What industries commonly use these PVC profiles?Our PVC profiles are used in various industries, including residential, commercial, and industrial applications, offering versatile solutions for different cooling equipment.

- How do manufacturers ensure the quality of these PVC profiles?We implement rigorous quality control processes, including thermal shock and UV tests, to ensure our PVC profiles meet industry standards and exceed customer expectations.

- What is the warranty period for your PVC profiles?We provide a one-year warranty on our PVC profiles, along with comprehensive after-sales support to address any product concerns.

- Can I get samples for testing?Yes, we offer samples upon request, allowing clients to assess the quality and suitability of our PVC profiles for their cooler systems before making a purchase decision.

Product Hot Topics

- The Role of PVC Profiles in Energy Efficiency

PVC profiles play a crucial role in enhancing the energy efficiency of cooler systems. Their low thermal conductivity minimizes heat transfer, maintaining optimal internal temperatures without excessive energy consumption. For manufacturers looking to improve the sustainability of their cooling solutions, PVC profiles offer an ideal balance of cost-effectiveness and performance. Their versatility in design also allows for customized solutions that can fit various cooling applications, thereby contributing significantly to energy-saving efforts across industries.

- Customization of PVC Profiles for Cooler Systems

Manufacturers increasingly seek customization options for PVC profiles to meet specific cooler system requirements. This customization might include adjusting the thickness for enhanced durability, altering colors for aesthetic purposes, or adding UV-resistant additives for outdoor applications. The ability to tailor these profiles to precise specifications is a significant advantage for manufacturers, offering flexibility and adaptability in diverse scenarios. The innovation in design not only caters to performance enhancements but also aligns with aesthetic preferences, which is crucial in competitive markets.

- Durability of PVC Profiles in Harsh Environments

PVC profiles are engineered to withstand harsh environmental conditions, making them a preferred choice in the manufacturing of cooler systems. Their inherent resistance to corrosion and UV degradation ensures long-lasting performance, even in settings exposed to moisture and sunlight. As manufacturers strive for durability in their products, these profiles offer reliable performance that ensures the longevity of cooling systems. Their robust construction supports structural integrity and minimizes maintenance needs, offering cost savings in the long run.

- The Economic Benefits of Using PVC Profiles

Choosing PVC profiles presents economic advantages for manufacturers and end-users alike. Their low cost compared to alternative materials offers budget-friendly solutions without sacrificing quality. Additionally, the lightweight nature of PVC profiles reduces transportation and installation costs, further enhancing their economic appeal. For manufacturers focused on delivering high-value products without escalating costs, PVC profiles represent a viable and efficient solution in the cooler systems market.

- Advancements in PVC Profile Manufacturing

Recent advancements in the manufacturing of PVC profiles have led to improvements in both quality and performance. From enhanced extrusion techniques to the incorporation of additives for improved UV resistance, manufacturers are continually evolving their processes to meet market demands. These enhancements not only improve the product's performance but also its environmental impact, aligning with the industry's shift towards more sustainable practices. Manufacturers that embrace these innovations are better positioned to offer superior products in the competitive cooler systems market.

- PVC Profiles and Environmental Impact

The environmental impact of PVC profiles is an essential consideration for manufacturers seeking sustainable solutions. PVC's recyclability and the reduced energy required for its production compared to metals make it a more environmentally friendly choice. Manufacturers committed to sustainable practices benefit from the material's eco-friendly attributes, offering cooler systems that align with green building standards. This focus on sustainability is increasingly crucial as consumers and industries prioritize environmentally responsible products.

- Impact of PVC Profiles on Cooler Design

PVC profiles significantly influence the design possibilities for cooler systems. Their flexibility in shape and size enables manufacturers to innovate in cooler system designs, accommodating unique airflow requirements and aesthetic preferences. The adaptability in design offered by PVC profiles opens up new possibilities for manufacturers aiming to differentiate their products in the marketplace. By leveraging these design capabilities, manufacturers can create cooler systems that are both efficient and visually appealing.

- The Technical Aspects of PVC Profile Production

Understanding the technical aspects of PVC profile production is crucial for manufacturers seeking to optimize quality and efficiency. The extrusion process, which involves heating PVC compounds and shaping them through molds, requires precision to achieve consistent results. Advances in extrusion technology, including automation and precision controls, have enhanced the production quality of PVC profiles. Manufacturers that invest in state-of-the-art extrusion facilities are likely to achieve higher standards of quality, ensuring their products meet rigorous industry demands.

- Integration of PVC Profiles in Cooler Systems

The integration of PVC profiles in cooler systems is a strategic move for manufacturers aiming to improve product performance. These profiles not only provide essential structural support but also enhance functional elements such as thermal insulation and airflow management. As manufacturers design new cooler systems, the inclusion of PVC profiles allows for lighter and more efficient products, catering to the growing demand for high-performance cooling solutions. The role of PVC profiles in this integration underscores their importance in modern cooler system design and function.

- Quality Assurance in PVC Profile Manufacturing

Quality assurance is a critical component of PVC profile manufacturing, ensuring that products meet specified standards and performance requirements. Manufacturers employ various testing methods, such as thermal cycling and UV exposure tests, to validate the durability and effectiveness of their PVC profiles. By adhering to strict quality control measures, manufacturers not only guarantee product reliability but also build trust with clients and end-users. This assurance is vital for maintaining competitive advantage and customer satisfaction in the demanding cooler systems market.

Image Description