Product Main Parameters

| Parameter | Description |

|---|---|

| Glass Type | Double Tempered Low-E Glass |

| Frame Material | Aluminum Alloy and PVC |

| Thickness | 4mm Tempered Low-E Glass |

| Temperature Range | -30℃ to 10℃ |

| Color Options | Silver, Black, Customizable |

Common Product Specifications

| Specification | Details |

|---|---|

| Glass Thickness | 3.2/4mm 12A 3.2/4mm |

| Insulation | Double/Triple Glazing |

| Insert Gas | Argon; Krypton Optional |

| Temperature Range | -30℃ to -10℃; 0℃ to 10℃ |

| Door Quantity | 1-7 Open Glass Doors |

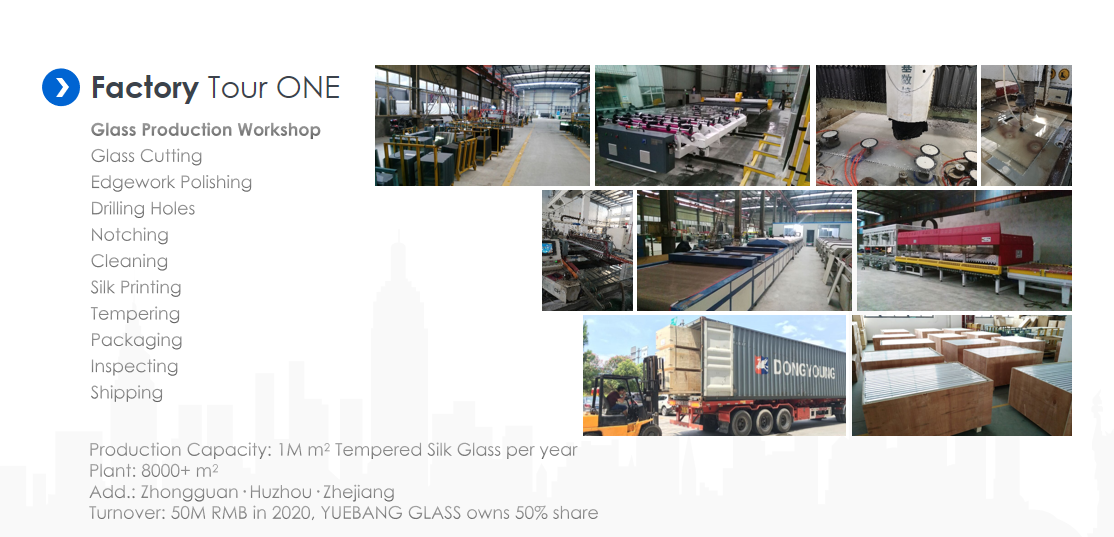

Product Manufacturing Process

As outlined in authoritative sources, the manufacturing of vertical freezer glass doors by leading manufacturers involves a multi-step process to ensure durability and quality. Initial steps include precise glass cutting and edge polishing to prepare the material. Next, any holes or notches needed are drilled. The glass is then cleaned thoroughly before silk printing and tempering, which enhances strength significantly. This tempered glass is crucial for both insulating performance and safety standards. Frames are constructed using high-grade aluminum or PVC, and assembly involves exacting standards to ensure airtightness and energy efficiency. Each step is optimized to deliver a product that meets international quality benchmarks.

Product Application Scenarios

Vertical freezer glass doors, as utilized by top manufacturers, find broad application across diverse sectors. In retail environments like supermarkets or convenience stores, they provide clear visibility which enhances product display while minimizing energy consumption due to reduced door opening frequency. In the food service industry, restaurants, and cafes benefit from their streamlined design which ensures quick access and efficient operations. In the residential context, although less common, these doors can complement modern kitchen aesthetics and simplify frozen goods storage. As discussed in industry papers, these applications underscore the versatility and practicality of these doors, making them a preferred choice across various markets.

Product After-sales Service

We offer comprehensive after-sales service, which includes free spare parts for a year and expert assistance in addressing any issues. Our dedicated customer support team is always available to help resolve any concerns you may have with your vertical freezer glass doors.

Product Transportation

All products are securely packaged with EPE foam and seaworthy wooden cases to ensure they arrive at your destination intact. We ship globally from major ports such as Shanghai and Ningbo, ensuring timely and safe delivery.

Product Advantages

- Energy-efficient with low-E glass technology.

- Enhanced visibility with anti-fog and anti-condensation features.

- Customizable design to meet diverse market needs.

- Robust construction offering longevity and reliability.

- Excellent thermal insulation properties.

Product FAQ

- Q: Are you a manufacturer or trading company? A: We are one of the leading manufacturers, proudly inviting you to visit our factory for a firsthand experience of our production process and quality control measures.

- Q: What is your minimum order quantity (MOQ)? A: The MOQ varies depending on the product design. Please contact us with your specific requirements to receive detailed information.

- Q: Can I apply my logo on the doors? A: Yes, customization is available, including logo placement and other design elements to align with your branding needs.

- Q: Do you offer customized products? A: Absolutely, we tailor our vertical freezer glass doors to fit specific size, color, and design requirements from our clients.

- Q: What warranty do you provide? A: We offer a one-year warranty on all our products, ensuring peace of mind and reliability.

- Q: How can I make a payment? A: We accept multiple payment methods including T/T, L/C, and Western Union, offering flexibility and convenience for our clients.

- Q: What is the lead time for order fulfillment? A: For items in stock, the lead time is approximately 7 days. For custom orders, it typically ranges from 20 to 35 days post-deposit.

- Q: How do you ensure product quality? A: We adhere to stringent quality control protocols, including comprehensive tests like thermal shock, condensation, and aging tests, ensuring all products meet industry standards.

- Q: What makes your product energy-efficient? A: Our use of double or triple-pane low-E glass, coupled with argon gas filling, significantly reduces heat transfer, optimizing energy efficiency.

- Q: Can the doors withstand extreme temperature variations? A: Yes, our doors are designed to function effectively within a temperature range of -30℃ to 10℃, making them suitable for various climates and storage needs.

Product Hot Topics

- Efficient Energy Solutions by Leading Manufacturers

Vertical freezer glass doors are becoming an industry benchmark for energy efficiency. Our manufacturers leverage advanced low-E glass technology combined with innovative insulating methods, leading to significant energy savings while maintaining optimal cooling conditions. This not only reduces operational costs but also supports environmental sustainability efforts, making it a popular choice among businesses aiming for eco-friendly solutions.

- Versatility in Design and Application

One of the outstanding features of our vertical freezer glass doors is their adaptability to various settings. From bustling supermarkets to upscale residential kitchens, their sleek design and customizable features cater to a wide range of environments. Our manufacturers have prioritized versatility, ensuring that the doors not only fulfill practical cooling needs but also enhance aesthetic appeal wherever they're installed.

- Enhanced Customer Experience in Retail

Retailers are increasingly adopting vertical freezer glass doors to improve customer shopping experiences. The clear, condensation-resistant glass provides an unobstructed view of products, influencing purchasing decisions positively. As manufacturers, we understand the pivotal role of visibility in retail settings and have optimized our designs to meet these needs, promoting better inventory management and customer engagement.

- Strategic Investments in Modern Manufacturing Techniques

Manufacturers of vertical freezer glass doors are continually investing in state-of-the-art technology to enhance product quality. Recent additions include automated cutting and polishing machinery, which improve precision and efficiency. These strategic investments underline our commitment to delivering superior products at competitive prices, positioning us as leaders in the refrigeration industry.

- Global Reach and Local Expertise

Our manufacturers have established a robust global presence, exporting vertical freezer glass doors to diverse markets like Japan, Korea, and Brazil. This global reach is supported by deep local expertise, ensuring that our products meet regional standards and customer preferences. This dual focus enables us to cater to a wide spectrum of needs, ensuring satisfaction and reliability across markets.

- Commitment to Sustainability

Sustainability is a core focus for the leading manufacturers of vertical freezer glass doors. By employing eco-friendly materials and processes, we are reducing our carbon footprint and promoting environmental responsibility. This commitment not only aligns with global sustainability goals but also highlights our dedication to leading the way in responsible manufacturing practices.

- Emphasis on Quality Control and Assurance

Quality is non-negotiable for our manufacturers, and we've instituted rigorous quality assurance processes to maintain high standards. From material selection to the final inspection, each step is meticulously monitored to ensure product integrity and customer satisfaction. This focus on quality control underlines our reputation as reliable suppliers of premium vertical freezer glass doors.

- Innovations in Product Development

Innovation drives our product development, with manufacturers continually exploring new technologies and materials. Recent advancements include smart glass options and improved sealing techniques, enhancing energy efficiency and user interaction. By staying at the forefront of innovation, we ensure our vertical freezer glass doors remain competitive and cater to evolving market demands.

- Customer-centric Approach to Service

Understanding customer needs is at the heart of our approach. Manufacturers prioritize feedback and adapt products accordingly, ensuring that vertical freezer glass doors meet specific client requirements. This customer-centric strategy fosters long-term relationships and positions us as preferred partners for businesses seeking reliable cooling solutions.

- Challenges and Opportunities in the Market

The market for vertical freezer glass doors presents unique challenges and opportunities. As manufacturers, navigating these involves balancing cost efficiency with high-quality production. The growing demand for sustainable and energy-efficient solutions offers significant potential for growth, pushing us to innovate continually and meet industry needs adeptly.

Image Description