Product Main Parameters

| Feature | Details |

|---|---|

| Glass Type | Tempered, Low-E |

| Insulation | Double Glazing, Triple Glazing |

| Gas Insert | Argon, Krypton optional |

| Glass Thickness | 3.2/4mm 12A 3.2/4mm |

| Frame | PVC, Aluminum, Stainless Steel |

| Temperature Range | 5℃-22℃ |

| Door Quantity | 1 Open Glass Door |

Common Product Specifications

| Attribute | Specification |

|---|---|

| Color | Black, Silver, Red, Blue, Green |

| Seal | Polysulfide & Butyl |

| Handle | Recessed, Add-on, Customized |

| Accessories | Self-closing hinge, magnet gasket |

| Usage Scenario | Bar, Office, Family Use |

Product Manufacturing Process

The manufacturing of wine refrigerator glass doors involves multiple stages, starting with the selection of premium glass materials. The process includes glass cutting, edge polishing, drilling, and notching. The glass is then thoroughly cleaned and subjected to silk printing if required. Tempering is a critical phase where the glass is hardened to enhance durability and resistance to impacts. Next, the glass is assembled into insulated units with argon or krypton filling for better thermal insulation. The frames are manufactured through advanced PVC extrusion or aluminum and stainless steel fabrication. Each unit undergoes rigorous quality control checks, including thermal shock tests and UV resistance testing, ensuring maximum performance and longevity. According to authoritative papers, implementing advanced tempering and insulation technologies in manufacturing not only improves energy efficiency but also significantly extends the lifespan of the glass doors.

Product Application Scenarios

Wine refrigerator glass doors find extensive use in various settings, enhancing both functionality and aesthetics. In residential applications, these doors offer a sophisticated look in home wine cellars or kitchen areas, appealing to wine connoisseurs who appreciate displaying their collections. In commercial spaces, such as restaurants, bars, and hotels, these glass doors not only preserve the quality of the wine but also serve as a marketing feature, allowing patrons to view selections conveniently. Research indicates that the integration of aesthetically pleasing and functional glass doors into commercial wine storage enhances customer engagement and boosts sales, as it aligns with contemporary interior design trends.

Product After-sales Service

Leading manufacturers provide comprehensive after-sales support, offering free spare parts and a two-year warranty on all wine refrigerator glass doors. Customers can access a dedicated support team for troubleshooting and replacement parts as needed, ensuring long-term satisfaction and product reliability.

Product Transportation

Products are securely packed using EPE foam and seaworthy wooden cases to prevent damage during transit. Shipping logistics are handled with precision to ensure timely delivery to global partners.

Product Advantages

- High Durability: Made from tempered Low-E glass, providing superior strength and longevity.

- Energy Efficiency: Advanced insulation techniques ensure minimal temperature fluctuation.

- UV Protection: Special coatings on the glass block harmful UV rays, preserving wine quality.

- Customizable Aesthetics: Available in multiple colors and handle designs to suit various tastes.

- Convenient Maintenance: Easy-to-clean surfaces and accessible components help maintain functionality.

Product FAQ

- What types of glass are used in your refrigerator doors?

As a leading manufacturer, we use high-quality tempered Low-E glass to ensure longevity and superior performance in all wine refrigerator glass doors.

- How do manufacturers ensure the UV resistance of these doors?

Manufacturers apply special UV coatings during the production process, minimizing wine degradation from light exposure and enhancing storage life.

- Can the glass door resist temperature fluctuations?

Yes, manufacturers employ advanced insulating techniques that stabilize internal temperatures, reducing fluctuations and energy consumption.

- How do manufacturers address energy efficiency?

Through superior insulation and gas fills like argon, energy consumption is minimized, promoting cost-effective and environmentally friendly storage.

- Are these glass doors customizable?

Yes, manufacturers offer customization in design, color, and size to align with client specifications and brand aesthetics.

- What warranty do manufacturers provide?

Our manufacturers offer a two-year warranty alongside comprehensive after-sales services to support product longevity and customer satisfaction.

- How do you handle repairs or spare parts?

Manufacturers provide timely delivery of spare parts and professional support through a dedicated after-sales team to address any issues.

- What is the expected lifespan of these glass doors?

With proper maintenance, the durable construction of these doors typically ensures a long service life, enhancing value for investment.

- How are these doors packaged for transport?

Manufacturers use EPE foam and secure wooden cases, ensuring safe transit and arrival of undamaged products to global destinations.

- Do manufacturers offer installation support?

Many manufacturers provide comprehensive installation guides and optional professional installation services to ensure optimal setup and performance.

Product Hot Topics

- The Evolution of Wine Refrigerator Glass Door Design

Leading manufacturers have transformed the wine storage landscape by incorporating cutting-edge design and advanced technology in wine refrigerator glass doors. These innovations not only enhance the visual appeal of wine cellars but also significantly improve functionality. With features like dual-zone temperature control and UV-resistant coatings, manufacturers address both aesthetic and preservation needs.

- The Role of Manufacturers in Advancing Insulation Technology

Manufacturers play a crucial role in advancing insulation technology within wine refrigerator glass doors. By utilizing argon gas and superior sealing techniques, they achieve exceptional thermal regulation, reducing energy consumption and extending wine longevity. Such advancements reflect the commitment to quality and environmental sustainability in modern manufacturing processes.

- Customizing Your Wine Refrigerator Glass Door

Manufacturers now offer extensive customization options for wine refrigerator glass doors, allowing for greater design flexibility to match varied interiors and personal preferences. Choices in color, material, and handle styles enable bespoke solutions that cater to both residential and commercial installations, ensuring that clients can express individuality through their wine storage.

- Understanding the Different Glass Types Used by Manufacturers

The selection of glass types by manufacturers is a key consideration impacting the performance of wine refrigerator doors. The use of tempered Low-E glass and optional triple glazing enhances durability and UV protection, providing a sophisticated solution for modern wine connoisseurs who prioritize both function and style.

- Eco-Friendly Manufacturing Practices in Wine Refrigerator Doors

Increasingly, manufacturers are adopting eco-friendly practices in producing wine refrigerator glass doors. From energy-efficient production methods to recyclable materials, these initiatives demonstrate a commitment to sustainable development, aligning with global trends towards greener manufacturing solutions.

- Comparing Insulation Options in Wine Refrigerator Glass Doors

Insulation efficiency is a major selling point for wine refrigerator glass doors. Manufacturers offer various options, including double and triple glazing with gas fillings like argon and krypton, to enhance thermal performance. Understanding these options helps consumers make informed decisions when selecting their ideal wine storage solutions.

- Manufacturers' Commitment to Quality Assurance in Wine Refrigerator Doors

Quality assurance is paramount for manufacturers producing wine refrigerator glass doors. Through rigorous testing protocols, including thermal shock and UV resistance assessments, manufacturers ensure that their products meet the highest standards of durability and functionality, garnering consumer trust and satisfaction.

- Innovations in Temperature Control by Leading Manufacturers

Temperature control is a critical concern addressed by manufacturers in wine refrigerator glass door design. By implementing advanced thermostatic systems and multiple temperature zones, manufacturers offer tailored solutions that cater to diverse wine collections, meeting the demands of sophisticated wine aficionados worldwide.

- The Impact of Manufacturers on the Global Wine Storage Market

Manufacturers have a significant impact on the global wine storage market by delivering high-quality wine refrigerator glass doors that combine elegance with efficiency. Their innovative approaches to design and technology continue to push the boundaries of wine storage, influencing market trends and consumer expectations.

- The Importance of After-Sales Service from Wine Refrigerator Door Manufacturers

After-sales service is a crucial aspect of the customer experience with wine refrigerator glass doors. Reputable manufacturers provide comprehensive support, including warranty services and readily available spare parts, ensuring customer satisfaction and reinforcing brand loyalty post-purchase.

Image Description

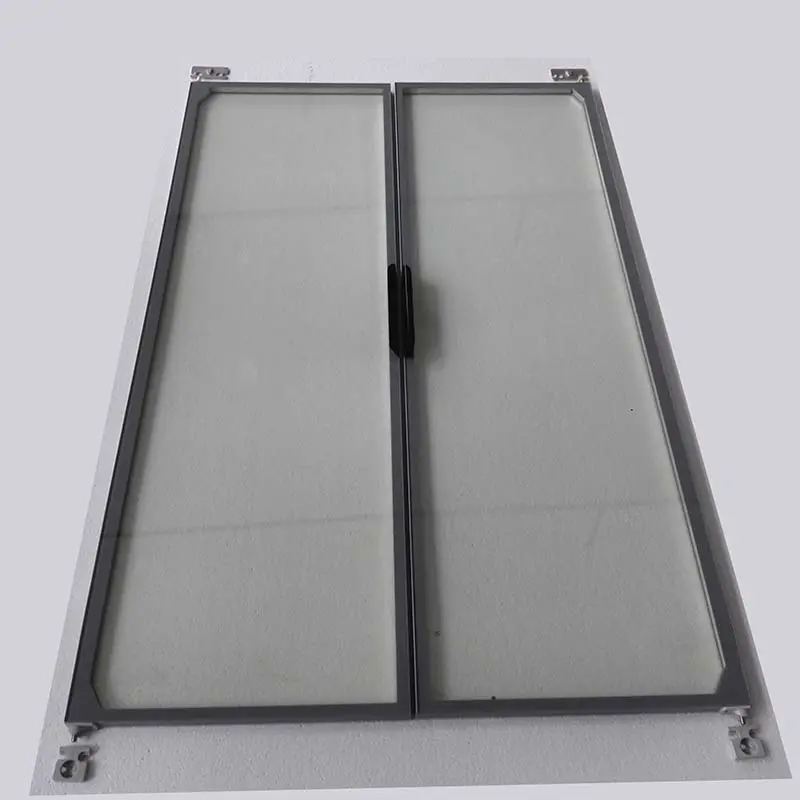

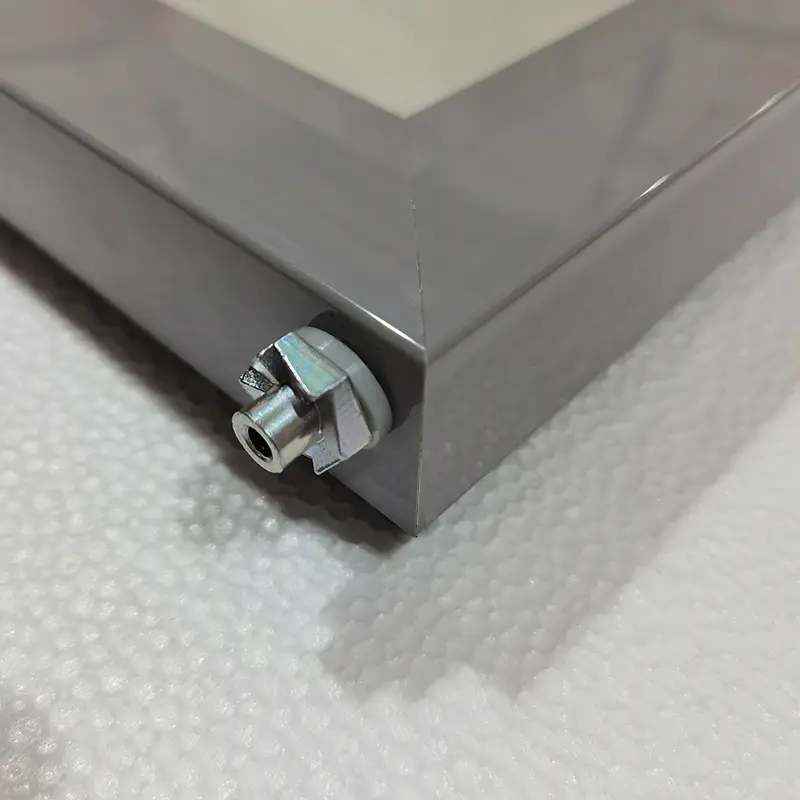

There is no picture description for this product