Understanding the Importance of Cooler Glass Doors

● Role in Energy Efficiency

Cooler glass doors are more than mere barriers to cold air—they are integral to the energy efficiency of refrigeration units. By maintaining an optimal interior environment, these doors help reduce energy consumption significantly. High-quality cooler glass doors minimize heat exchange, thus ensuring the refrigeration unit operates within its optimal range, reducing unnecessary energy expenditure. When considering upgrades, it's essential to choose options that enhance the thermal performance of your coolers.

● Visibility and Display Benefits

In addition to energy efficiency, cooler glass doors are essential for product visibility and customer engagement. For retailers, a well-lit and organized display behind a clear glass door can drive impulse purchases. Ensuring that cooler glass doors are clean, transparent, and resistant to fogging is key. This not only enhances customer experience but also increases the likelihood of sales, particularly in environments like supermarkets and convenience stores.

Choosing the Right Glass Material

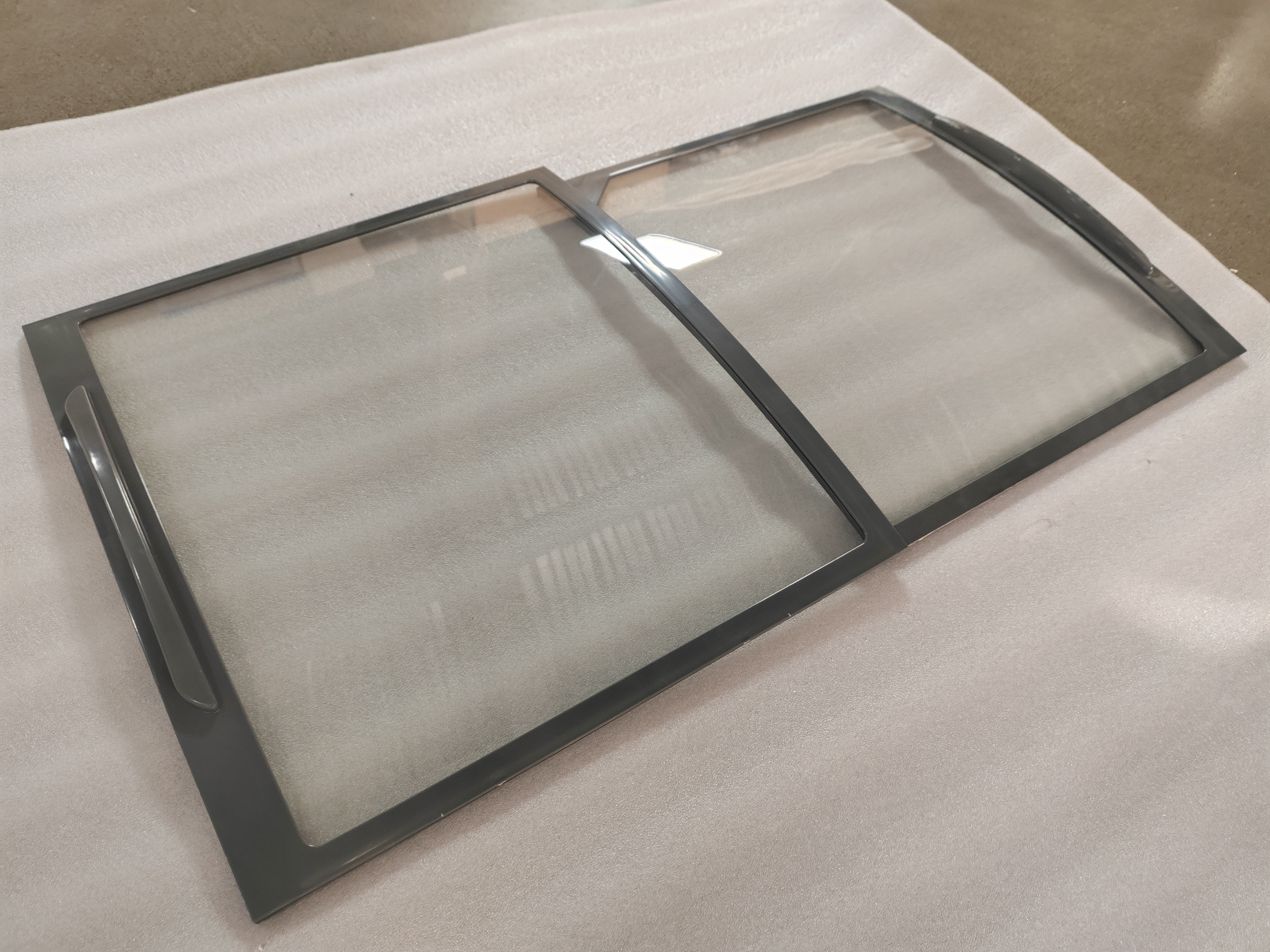

● Insulated vs. Non-Insulated Glass

The choice between insulated and non-insulated glass can significantly impact the performance of cooler doors. Insulated glass, typically consisting of multiple panes with a layer of inert gas in between, is highly effective in minimizing heat transmission. This type of glass is essential for maintaining consistent internal temperatures and improving energy efficiency in cooler units. Conversely, non-insulated glass, while cheaper, may not provide the same level of thermal protection and can lead to higher energy costs over time.

● Impact of Glass Thickness

Glass thickness is another critical factor influencing the efficacy of cooler doors. Thicker glass often provides better durability and insulation; however, it may also increase the overall weight of the door, impacting the ease of use and the wear on hinges and handles. Therefore, it’s crucial to strike a balance between thickness for insulation and practical usability, ensuring that doors remain functional and efficient over their lifespan.

Implementing Energy-Efficient Technologies

● Low-E Coatings

Low-emissivity (Low-E) coatings are a technological innovation that can significantly enhance the energy efficiency of cooler glass doors. These coatings reflect thermal energy, thus reducing the amount of heat passing through the glass. By applying Low-E coatings, the cooler glass door factory can produce doors that not only maintain internal temperatures but also optimize energy use. This translates into cost savings on electricity bills and contributes to a sustainable business model.

● Double or Triple Glazing Options

For those seeking maximum insulation, double or triple-glazed cooler glass doors are an excellent choice. This option involves multiple layers of glass with air or gas-filled spaces between them, offering superior thermal performance. Cooler glass door manufacturers often recommend these options for environments where maintaining a stable temperature is critical. While the initial investment might be higher, the energy savings and durability over time justify the expense.

Regular Maintenance for Peak Performance

● Cleaning and Inspection Routines

To keep cooler glass doors operating efficiently, regular maintenance is vital. Establishing a routine for cleaning not only enhances visibility but also prevents the buildup of grime that can affect the door’s sealing capabilities. Regular inspections should focus on identifying any signs of wear and tear, such as cracks or seal degradation, that could compromise the door’s efficiency. By working with cooler glass door suppliers to maintain a consistent upkeep schedule, businesses can prolong the life and performance of their cooler units.

● Identifying and Fixing Seals

A critical component of cooler glass door efficiency is the condition of the door seals. Over time, seals can become worn or damaged, leading to air leaks that reduce the door’s effectiveness. Periodically checking and replacing seals is essential in maintaining energy efficiency. Many custom cooler glass door providers offer seal replacement services, ensuring that doors remain airtight and function optimally.

Smart Temperature Management Strategies

● Optimal Temperature Settings

Managing the temperature settings of cooler units is crucial for preserving product freshness and minimizing energy consumption. Setting temperatures too low can lead to unnecessary energy use, while temperatures that are too high risk compromising product quality. By using smart temperature management systems, cooler glass door users can achieve a balance that maintains product integrity without excessive energy expenditure.

● Monitoring and Automation Tools

Integrating monitoring and automation tools with cooler glass doors can further enhance their efficiency. These technologies provide real-time data on temperature fluctuations and door usage, allowing for precise control and adjustments. Automation tools can also alert staff to potential issues before they escalate, ensuring that cooler units operate within their optimal parameters at all times.

Upgrading to LED Lighting Solutions

● Benefits Over Traditional Lighting

Switching to LED lighting within cooler units can offer substantial benefits over traditional lighting options. LEDs are more energy-efficient, longer-lasting, and have a lower heat output, reducing the load on cooling systems. This conversion not only leads to cost savings but also enhances the appeal of products displayed behind cooler glass doors, as LED lights provide clearer, more vibrant illumination.

● Enhancing Product Display and Efficiency

Beyond energy savings, LED lighting can transform the visual appeal of products displayed in cooler units. By using strategically placed LEDs, businesses can highlight specific products, influence purchasing decisions, and create an inviting ambience. Cooler glass door suppliers frequently offer LED lighting upgrades as part of their service packages, recognizing the dual benefits of improved efficiency and enhanced customer experience.

Improving Door Seals and Gaskets

● Types of Seals

There are various types of seals used in cooler glass doors, each with distinct advantages. Magnetic seals, for example, ensure a tight closure by utilizing magnetic force, while compression seals rely on the door's gasket material to provide a barrier against air leakage. Selecting the appropriate type of seal based on door use and environmental requirements is vital for maintaining efficiency.

● Signs of Wear and Replacement Options

Recognizing signs of wear in door seals early can prevent more significant issues down the line. Common indications include difficulty in closing doors, visible cracks or breaks in the seal, and noticeable temperature fluctuations within the cooler unit. Cooler glass door manufacturers typically offer replacement options for seals, ensuring that units continue to perform optimally.

Incorporating Display and Marketing Elements

● Effective Use of Space

Maximizing the display space behind cooler glass doors is important for both functionality and marketing. A well-organized cooler not only makes it easier for customers to find what they’re looking for but also allows for strategic product placement. Custom cooler glass doors can be designed with shelving and storage solutions that optimize the use of available space, thereby improving overall customer satisfaction.

● Branding and Product Placement

A cooler’s door is also a marketing canvas. By using branding and product placement strategies, businesses can enhance their brand visibility and increase sales. Consider incorporating branded graphics on the cooler’s door or arranging products in a way that highlights bestsellers. By coordinating with cooler glass door suppliers, businesses can tailor their cooler displays to reflect their brand identity and marketing goals effectively.

Emphasizing Safety and Durability

● Shatterproof and Tempered Glass Options

Safety should never be compromised when it comes to cooler glass doors. Shatterproof and tempered glass options are designed to withstand impacts and reduce the likelihood of injury. These safety features are particularly important in high-traffic areas or facilities where accidents are more likely to occur. Cooler glass door factories often prioritize these materials to ensure the safety and satisfaction of their customers.

● Long-Term Wear and Tear Considerations

Understanding the long-term wear and tear of materials used in cooler glass doors is essential for making informed purchasing decisions. Over time, even the highest quality doors may show signs of aging, such as scratches, discoloration, or seal failure. Therefore, selecting durable materials and engaging in regular maintenance are key practices to ensure that cooler doors continue to perform efficiently over their lifespan.

Future Trends in Cooler Glass Technology

● Smart Glass Innovations

The evolution of cooler glass door technology continues with the advent of smart glass innovations. These include glass that can adjust its transparency based on temperature or light conditions, thus optimizing energy use and enhancing customer experience. Such advancements are set to revolutionize how cooler doors are used in commercial settings, offering new levels of efficiency and functionality.

● Sustainable and Eco-Friendly Solutions

As sustainability becomes increasingly important, cooler glass door manufacturers are focusing on eco-friendly solutions. This includes using recyclable materials, reducing energy consumption through advanced technologies, and designing doors that contribute to a building’s overall green credentials. Companies committed to sustainability are likely to benefit from these innovations, reducing their environmental impact while achieving operational efficiency.

Company Introduction

ZHEJIANG Yuebang GLASS CO.,LTD, located in Deqing County, Huzhou City, Zhejiang Province, China, is a leading manufacturer with over 20 years of expertise in commercial cooler/freezer glass doors. Yuebang specializes in the development, production, and sales of a wide range of products including cold room glass doors, vending machine glass with heating functions, and plastic extrusion profiles. With a state-of-the-art production facility spanning over 13,000m², Yuebang's commitment to quality and innovation has positioned them as a trusted partner for leading brands worldwide, delivering excellence in design, efficiency, and sustainable solutions. 2025-04-22 18:49:05

2025-04-22 18:49:05