Introduction

Vacuum Insulated Glass Doors have become a mainstay in modern architecture, known for their superior energy efficiency and sleek design. Unlike traditional glass doors, these innovative products offer enhanced thermal insulation, significantly reducing energy costs and improving indoor climate control. As demand grows, particularly from regions where energy conservation is prioritized, maintaining these advanced doors becomes crucial to maximize their benefits over a longer lifespan. This article delves into comprehensive maintenance strategies for Vacuum Insulated Glass Doors, focusing on preserving their integrity, efficiency, and aesthetic appeal. The maintenance advice is applicable whether you're sourcing from China Vacuum Insulated Glass Door suppliers, considering a Custom Vacuum Insulated Glass Door, or interacting with a Vacuum Insulated Glass Door Factory.

Understanding Vacuum Insulated Glass Doors

● Definition and Basic Components

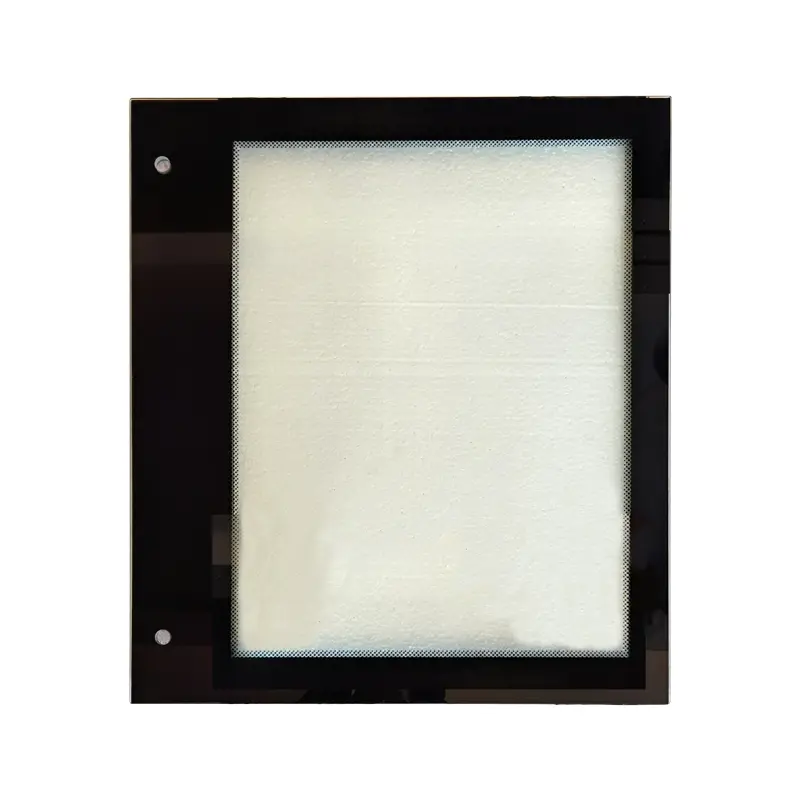

Vacuum Insulated Glass Doors, often sourced from leading Vacuum Insulated Glass Door Manufacturers, consist of two or more layers of glass separated by a vacuum space. This design drastically reduces heat transfer, offering excellent insulation properties. The vacuum acts as a superior insulator by minimizing convection and conduction, resulting in energy savings for homes and businesses.

● Benefits Over Traditional Glass Doors

Compared to traditional glass options, Vacuum Insulated Glass Doors provide better thermal performance, reduce condensation, and offer soundproofing benefits. Their durability and low maintenance requirements make them a popular choice for both residential and commercial applications.

Importance of Regular Maintenance

● Extending the Life of Your Glass Doors

Regular maintenance ensures that your Vacuum Insulated Glass Doors remain efficient and aesthetically pleasing for years. Simple practices can prevent the premature degradation of glass and its components, allowing you to enjoy the doors' full benefits.

● Preventing Common Issues Through Upkeep

Routine maintenance helps identify potential problems before they escalate. Issues like seal failure, visible condensation, or surface damage can often be mitigated with timely intervention, thereby preserving both the functionality and appearance of the doors.

Cleaning Your Vacuum Insulated Glass Doors

● Recommended Cleaning Products

To clean Vacuum Insulated Glass Doors effectively, use a mild, non-abrasive glass cleaner. Ensure that the product does not contain ammonia or harsh chemicals, which can scratch or cloud the glass.

● Do's and Don'ts of Cleaning

Do use a soft, lint-free cloth to clean the glass and frames. Don’t use abrasive pads or grit-laden cleaners that can damage the surface. Regular cleaning prevents the buildup of dirt and grime, preserving the glass's clarity.

Inspecting the Hermetic Seal

● Signs of a Compromised Seal

A compromised hermetic seal is one of the most common issues affecting the performance of Vacuum Insulated Glass Doors. Look for fogging between glass panes or feeling drafts, as these can indicate a seal failure.

● Steps to Maintain Seal Integrity

To maintain seal integrity, periodically check for visible damage around the door’s edges and ensure the doors are properly aligned. Professional Vacuum Insulated Glass Door Suppliers offer seal inspections and repairs to help maintain your doors' insulation properties.

Addressing Outgassing Concerns

● Understanding Outgassing and Its Effects

Outgassing refers to the release of trapped gases from the materials used in the construction of Vacuum Insulated Glass Doors. While generally not harmful, it can affect the appearance and performance of the glass doors.

● Techniques to Mitigate Outgassing

To mitigate outgassing, ensure the doors are installed properly to allow for adequate ventilation. Regular maintenance checks by a professional can also help to manage and minimize outgassing effects.

Protecting Against Physical Damage

● Tips for Preventing Scratches and Chips

To prevent physical damage, use protective films or mats in high-traffic areas. Ensure that door handles and hardware are in good condition to avoid accidental impacts that could chip or scratch the glass.

● Importance of Careful Handling

Educate users about the importance of careful handling and operation of Vacuum Insulated Glass Doors to avoid unnecessary damage. Proper training can significantly reduce the risk of physical damage over time.

Monitoring Thermal Efficiency Over Time

● How to Measure Thermal Performance

Thermal performance can be assessed using specialized tools to measure the U-value of the glass. A decline in thermal performance might indicate an issue with the vacuum seal or glass pane integrity.

● Signs of Declining Efficiency

Look for increased energy bills, drafts near the door, and condensation on the interior pane as signs that the thermal efficiency of your Vacuum Insulated Glass Doors may be declining.

Professional Maintenance and Inspections

● When to Call a Professional

If you notice persistent issues such as fogging, drafts, or difficulty in operation, it might be time to call in a professional. Many Vacuum Insulated Glass Door Manufacturers offer maintenance services to ensure optimal door performance.

● Benefits of Expert Evaluations

Professional evaluations can provide a comprehensive assessment of the door's condition and identify issues that may not be apparent to the untrained eye. This proactive approach can extend the lifespan of your Vacuum Insulated Glass Door significantly.

Importance of Manufacturer Recommendations

● Understanding Your Manufacturer’s Guidelines

Each Vacuum Insulated Glass Door Factory provides specific guidelines for care and maintenance. Adhering to these recommendations is crucial to avoid voiding warranties and ensure the longevity of your glass doors.

● Impact on Warranty and Lifespan

Failing to follow manufacturer recommendations can affect warranty coverage and reduce the overall lifespan of your doors. Regularly review the guidelines provided by your Vacuum Insulated Glass Door Suppliers to stay informed.

Long-term Benefits of Proper Maintenance

● Energy Savings and Cost Efficiency

Maintaining your Vacuum Insulated Glass Doors helps to retain their energy efficiency benefits, resulting in lower energy bills and a reduced carbon footprint. Over time, these savings can be significant.

● Enhanced Structural Integrity and Durability

Proper maintenance not only keeps your doors looking new but also ensures their structural integrity. Well-maintained doors are less likely to experience issues such as seal failure or glass breakage, contributing to their overall longevity.

Conclusion

Proper care and maintenance of your Vacuum Insulated Glass Doors are essential for maximizing their benefits and lifespan. Whether you are dealing with a China Vacuum Insulated Glass Door or a Custom Vacuum Insulated Glass Door, regular inspections, cleaning, and adherence to manufacturer guidelines will help you retain their performance and appearance. By doing so, you ensure the long-term efficiency and durability of your investment.

Company Introduction:YUEBANG

ZHEJIANG YUEBANG GLASS CO.,LTD is located in Deqing County, Huzhou City, Zhejiang Province, China. With over 20 years of experience, Yuebang specializes in producing Commercial Cooler/Freezer Glass Doors and various other glass products. The company boasts a 13,000m² plant area with advanced production facilities capable of producing high-quality tempered and insulated glass. Yuebang's commitment to quality and innovation has established partnerships with renowned brands worldwide, ensuring the provision of exceptional glass solutions tailored to customer needs. 2025-01-20 20:33:07

2025-01-20 20:33:07