Product Main Parameters

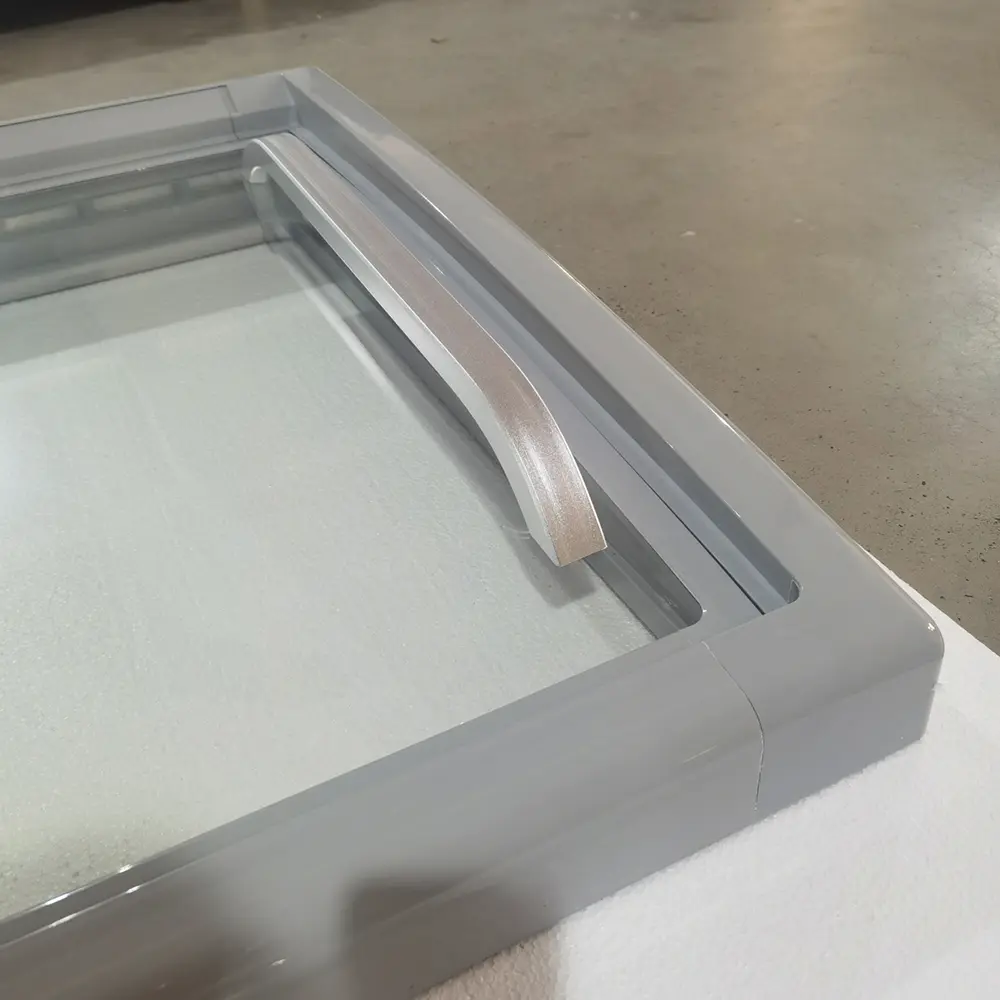

| Product Name | Commercial Deep Island Chest Freezer Flat Sliding Glass Door |

|---|---|

| Glass Material | 4±0.2MM Tempered Low-E glass |

| Frame Material | ABS for width, PVC extrusion for length |

| Size | Width: 815MM, Length: Customized |

| Shape | Flat |

| Frame Color | Gray, customizable |

| Temperature | -30℃ to 10℃ |

| Application | Chest Freezer/Island Freezer/Deep Freezer |

| Package | EPE foam Seaworthy wooden case |

| Service | OEM, ODM |

| Warranty | 1 Year |

Common Product Specifications

| Visual Light Transmittance | ≥80% |

|---|---|

| Solar Energy Transmittance | High |

| Reflectance Rate | High for far infrared radiation |

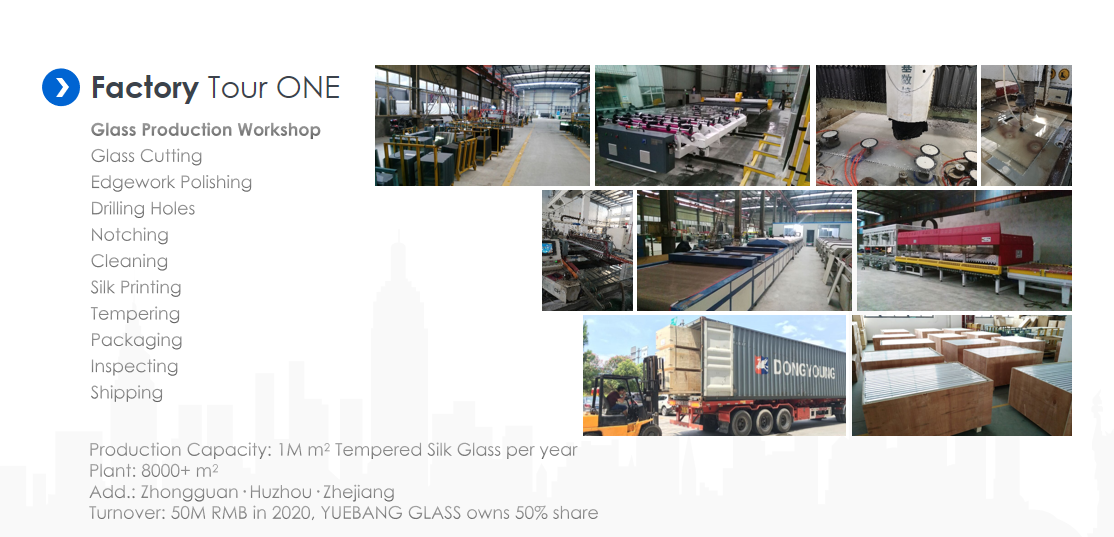

Product Manufacturing Process

The manufacturing process of glass doors for refrigerators typically involves precise steps to ensure quality and durability. Starting with glass cutting, where large sheets of glass are cut to the required size using precision tools. Next, edge polishing smooths out the raw edges to prevent injuries and ensure a clean fit within door frames. The glass is then subjected to drilling and notching to create necessary holes and slots for handles and hinges. A cleaning process ensures the glass is free of any debris that might affect appearance or adhesion. Silk printing can be applied for branding or decorative purposes, followed by the tempering process, where the glass is heated and rapidly cooled to increase strength and thermal resistance. After tempering, insulating glass units are created by assembling multiple glass layers with a spacer, often filled with argon gas, to enhance thermal efficiency. The frames, made from PVC extrusion and ABS materials, are assembled, and the final product undergoes stringent quality checks before packing and shipment. This meticulous process ensures suppliers provide a high-quality and reliable Glass Door For Refrigerator.

Product Application Scenarios

The Glass Door For Refrigerator is increasingly favored in both commercial and residential settings due to its aesthetic appeal and functional benefits. In commercial spaces such as supermarkets, restaurants, and cafes, glass doors enhance product visibility, encouraging impulse purchases while maintaining optimal temperature control for perishable goods. Their transparency allows suppliers to display a variety of products, from beverages to gourmet foods, in an appealing manner that attracts customers’ attention. In residential kitchens, glass doors offer a modern and sophisticated look, making refrigerators a focal point in kitchen design. Homeowners who enjoy showcasing their culinary collections appreciate the visibility, while the technology behind double or triple glazing ensures energy efficiency. In both settings, glass doors facilitate organization, as contents are easily visible, reducing the time spent searching for items and minimizing the escape of cold air. Suppliers offering customizable options for shape, size, and color further allow these doors to seamlessly integrate into various environments, fulfilling both aesthetic and practical needs.

Product After-Sales Service

- Free Spare Parts

- Online Support

- Warranty Service: 1 Year

Product Transportation

- Secure Packaging: EPE foam and seaworthy wooden cases

- Global Shipping Partners

- Efficient and Reliable Delivery Solutions

Product Advantages

- Enhanced Visibility and Display Options

- Energy Efficiency through Low-E Glass

- Durability with Tempered Glass Construction

- Customization Available

- Modern Aesthetic Appeal

Product FAQ

- Are you a manufacturer or trading company?

We are a manufacturer specializing in high-quality Glass Door For Refrigerator. Our factory is open for visits by potential suppliers and clients.

- What is the MOQ for your products?

The minimum order quantity varies by design. Please provide us with your design needs, and we will inform you of the corresponding MOQ.

- Can I use my logo on the products?

Yes, we offer customization options for your brand logo, enhancing your product’s market presence alongside our quality manufacturing.

- Is product customization possible?

Absolutely, customization in terms of glass dimensions, frame colors, and more is available to meet diverse supplier demands.

- What warranty do you offer?

We provide a one-year warranty on all our Glass Door For Refrigerator products, offering peace of mind in case of manufacturing defects.

- How can I make payments?

We accept various payment methods, including T/T, L/C, and Western Union, to facilitate straightforward transactions with suppliers.

- What’s the lead time for orders?

Standard lead time is 7 days for in-stock items. Custom orders take approximately 20-35 days post-deposit, ensuring tailored production.

- What is your pricing strategy?

Prices are determined by the order quantity, offering competitive rates to suppliers seeking bulk purchases. Contact us for precise pricing.

- What packaging solutions do you offer?

Our products are packaged with EPE foam and shipped in seaworthy wooden cases, ensuring safe transit and delivery to our global suppliers.

- Do you offer after-sales support?

Yes, we provide comprehensive after-sales services, including free spare parts and online support, to assist our suppliers post-purchase.

Product Hot Topics

- Why are Glass Doors For Refrigerators gaining popularity?

Glass doors are becoming increasingly popular among suppliers due to their ability to simultaneously enhance aesthetic appeal and functional utility. In commercial settings, they promote product visibility, which is crucial for merchandising, while in residential kitchens, they add a touch of modern elegance. The demand from suppliers for energy-efficient solutions is also driving this trend, with advanced glazing technologies reducing the typical insulation drawbacks of traditional glass. As manufacturers continue to innovate, these doors are expected to address both environmental and aesthetic considerations more effectively, cementing their place in the market.

- How do low-E glass doors contribute to energy savings?

Low-E glass doors are equipped with an invisible coating that reflects infrared and ultraviolet light, minimizing the amount of heat that passes through while preventing harmful rays that can fade interior furnishings. This reflective property significantly contributes to reducing the cooling load of refrigerators, which is a major draw for suppliers aiming to enhance the energy efficiency of their products. The use of argon gas between double or triple glazing further improves insulation, making low-E glass a preferred choice for environmentally conscious brands and consumers alike.

- What role does argon gas play in glazed refrigerator doors?

Argon gas, an inert gas used between glass panes in double or triple glazing, serves as an effective insulator. Its thermal conductivity is lower than that of air, which helps in minimizing heat transfer between the refrigerator interior and the external environment. For suppliers focused on energy-efficient design, this feature is key, as it helps maintain consistent internal temperatures, reduces compressor workload, and consequently lowers energy usage. Additionally, argon gas does not react with other substances, ensuring long-lasting performance of the insulated glass doors.

- What are the maintenance considerations for glass refrigerator doors?

Maintaining the pristine appearance of glass doors is a common concern among suppliers and consumers. Most modern designs incorporate special coatings that minimize fingerprints and smudges, which are common on glass surfaces. Routine cleaning with a soft cloth and non-abrasive cleaners is recommended to maintain clarity and cleanliness. Tempered glass offers robust durability, reducing concerns about breakage, though suppliers should inform users about potential risks and care instructions to ensure long-term satisfaction.

- Can suppliers benefit from customizable glass door solutions?

Customization is a significant advantage for suppliers looking to cater to specific market demands. By offering customizable options such as size, color, and glass type, suppliers can better serve diverse customer needs, ranging from residential homeowners to large-scale commercial clients. Custom options can also include specialized coatings or treatments that enhance performance, such as UV protection or enhanced thermal resistance, allowing suppliers to differentiate their products in a competitive marketplace.

- How does glass door technology affect refrigerator design?

Glass door technology plays a central role in modernizing refrigerator designs, appealing to consumers who value both form and function. Manufacturers and suppliers are leveraging advancements in glazing technology to create doors that not only showcase contents effectively but also minimize energy consumption. By integrating smart technology, such as variable opacity or digital displays, suppliers can offer products that blend seamlessly into smart home ecosystems, aligning with the evolving consumer preferences for high-tech solutions.

- What are the environmental impacts of using glass doors?

The environmental impact of using glass doors is multifaceted. Suppliers focused on sustainability appreciate that glass is a recyclable material, offering a circular approach to production. The energy savings achieved through enhanced insulation properties also contribute to a smaller carbon footprint over the product's lifecycle. As regulatory pressures for energy-efficient appliances increase, suppliers using advanced glass technologies can stay ahead of compliance requirements while contributing positively to environmental goals.

- Are glass doors suitable for all types of refrigerators?

While glass doors are versatile and can enhance a variety of refrigerator types, their suitability depends on the specific application and user needs. Suppliers should evaluate factors such as visibility preferences, energy efficiency requirements, and aesthetic considerations. Glass doors may be more suitable for display units or spaces where contents are frequently accessed and desired to be visible. In contrast, for applications where insulation is paramount, such as deep freezers, suppliers may need to consider alternative designs or enhanced glass treatments to meet performance standards.

- What future innovations can suppliers expect in glass door technology?

Future innovations in glass door technology are likely to focus on combining functionality with smart technology. Suppliers can expect to see advancements such as smart glass capable of changing opacity at the touch of a button, or integration with IoT devices for inventory management and energy monitoring. Enhanced coatings that provide not only thermal benefits but also antimicrobial properties could be developed as consumer health concerns drive demand for hygienic solutions. As technology evolves, suppliers equipped to adapt these innovations will be well-positioned to capture emerging market opportunities.

- How do suppliers ensure the quality of glass refrigerator doors?

Quality assurance is a critical aspect for suppliers of glass refrigerator doors. Rigorous testing, including thermal shock cycle tests, condensation tests, and mechanical strength evaluations, ensures that the final product meets safety and performance standards. Implementing continuous quality improvement programs and investing in advanced inspection technologies further bolster supplier reputations. By maintaining high-quality manufacturing processes, suppliers not only ensure compliance with industry regulations but also build trust with consumers and commercial clients.

- What are the market trends driving the demand for glass doors?

Several market trends are influencing the increased demand for glass doors in refrigerators. Consumers’ preference for sleek, modern appliances that complement contemporary home aesthetics is a significant driver. Additionally, heightened awareness of energy conservation and sustainable living is prompting suppliers to offer energy-efficient solutions. The proliferation of smart home technologies also supports the integration of smart glass features in evolving product designs. Suppliers who align their offerings with these trends are likely to meet growing consumer demands effectively, securing their market position.

Image Description