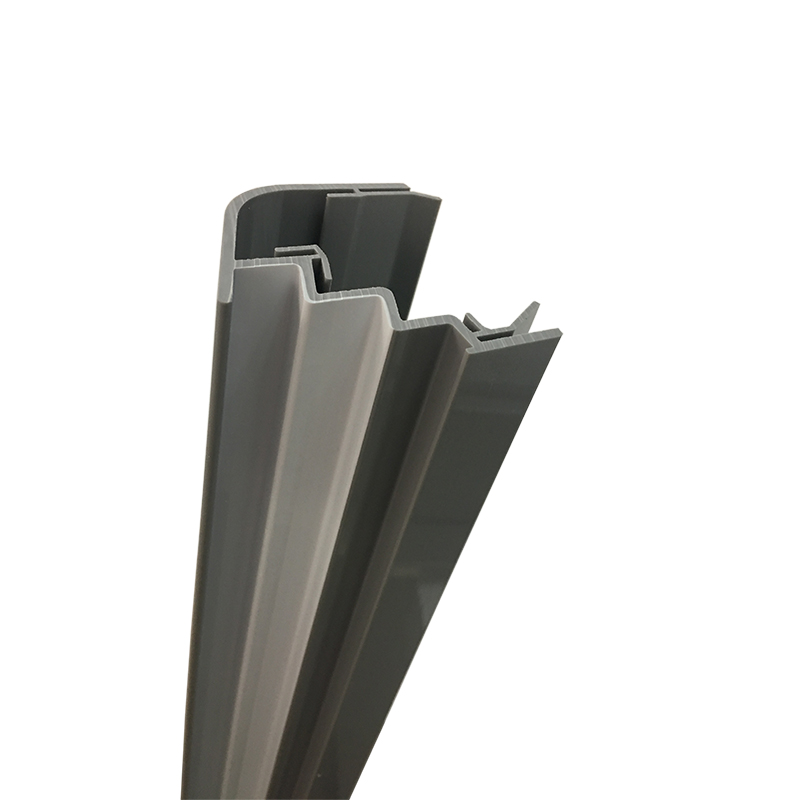

Product Main Parameters

| Product Name | Suppliers Plastic Extrusion Profile for Cooler |

|---|---|

| Material | PVC, ABS, PE |

| Type | Plastic Profiles |

| Thickness | 1.8-2.5MM or as Customer Required |

| Shape | Customized Requirement |

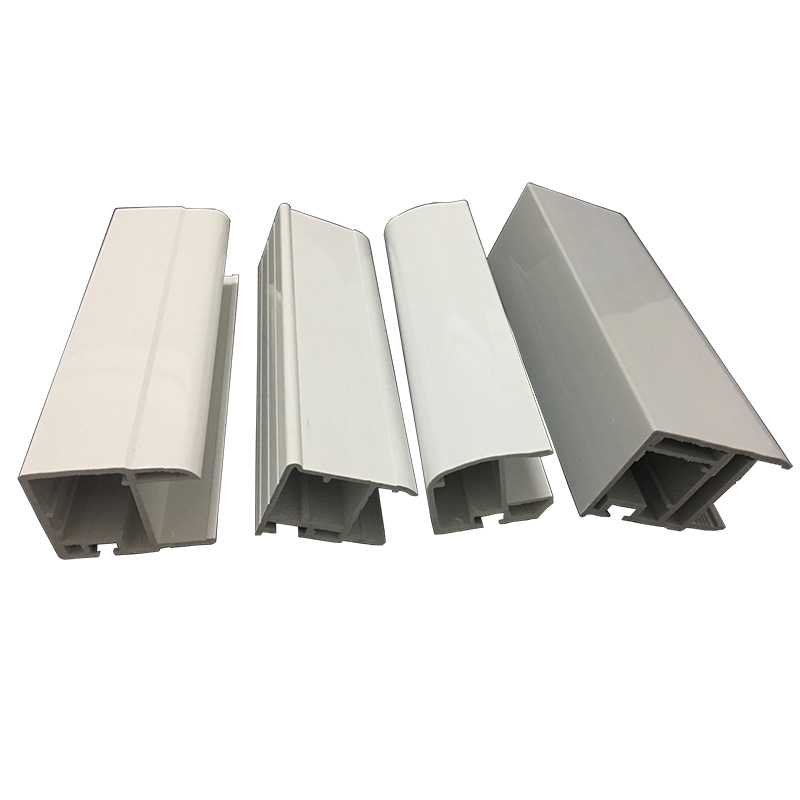

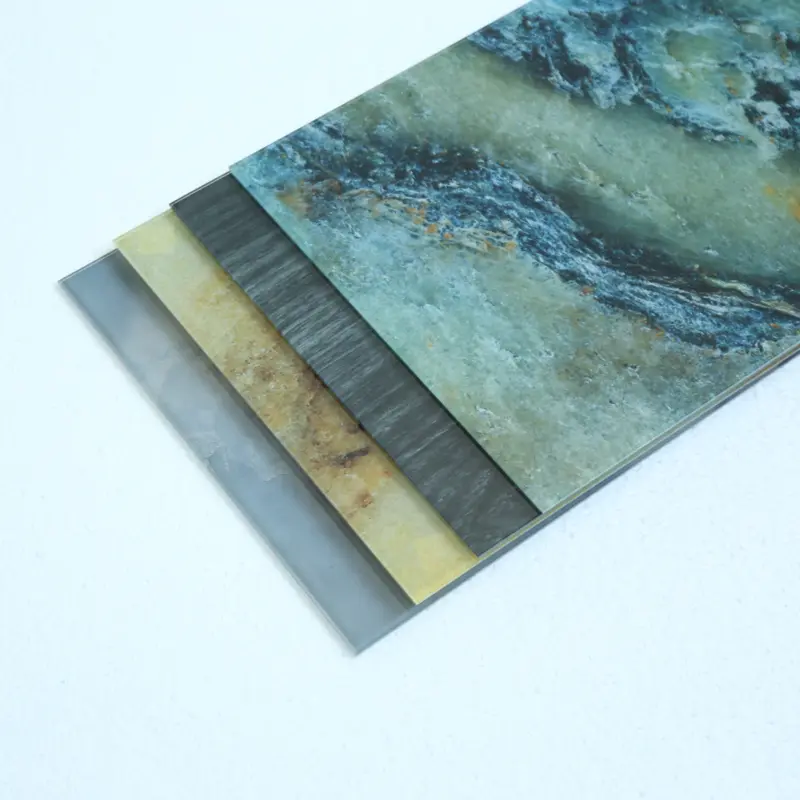

| Color | Silver, White, Brown, Black, Blue, Green, etc. |

| Usage | Construction, Building Profile, Refrigerator Door, Window, etc. |

Common Product Specifications

| Application | Hotel, House, Apartment, Office Building, School, Supermarket, etc. |

|---|---|

| Package | EPE foam Seaworthy wooden case (Plywood Carton) |

| Service | OEM, ODM, etc. |

| After-sales Service | Free Spare Parts |

| Warranty | 1 Year |

| Brand | YB |

Product Manufacturing Process

Plastic extrusion is a versatile manufacturing process essential in the production of profiles with a fixed cross-sectional outline. It utilizes plastic pellets that are melted and forced through a die to form continuous shapes. The process entails feeding raw material into a heated barrel where it is melted and shaped by a rotating screw. As it emerges from the die, the shaped plastic is cooled using air or water to retain its form. This process is noted for its precision and efficiency, especially in creating components for coolers. According to recent studies, the combination of high extrusion speed and control over polymer melting can enhance production efficiency significantly, making it a preferred method among Suppliers of Plastic Extrusion Profile for Cooler applications.

Product Application Scenarios

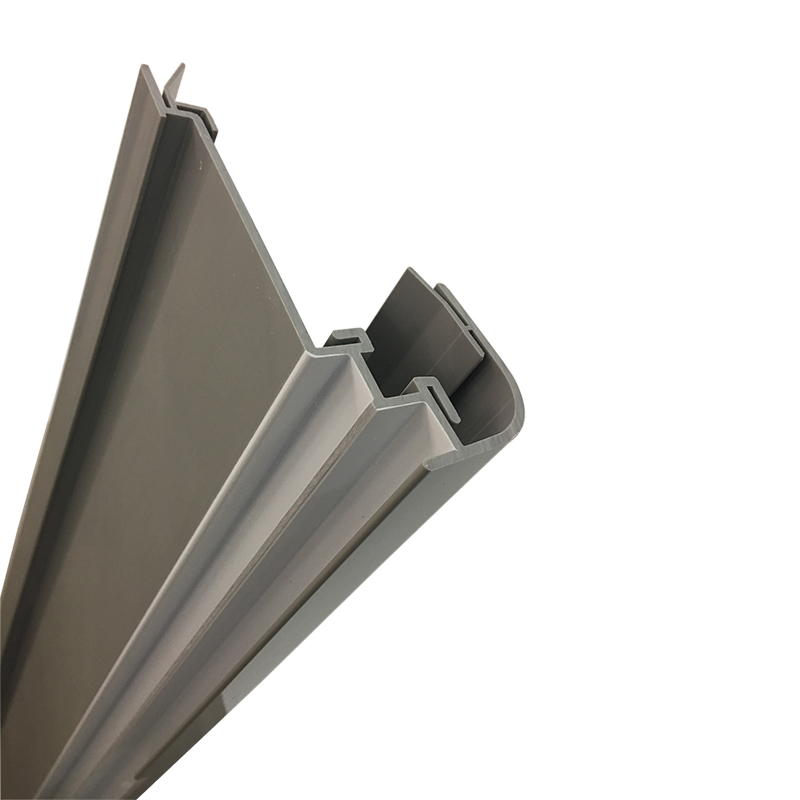

In cooler applications, plastic extrusion profiles are vital for various components. Structural frameworks benefit from extruded profiles due to their rigidity and lightweight nature, crucial for portable cooler designs. Seals and gaskets are produced through extrusion to ensure airtight closures, enhancing insulation performance. Furthermore, extruded profiles can be customized for handles, hinges, and housing for insulation panels, helping maintain optimal temperatures within. As noted by experts, the flexibility in design provided by extrusion processes allows Suppliers of Plastic Extrusion Profile for Cooler to innovate continually, meeting the evolving demands of modern refrigeration systems.

Product After-Sales Service

YB Suppliers offer comprehensive after-sales service including free spare parts and a one-year warranty, ensuring customer satisfaction and product reliability.

Product Transportation

Our profiles are securely packaged using EPE foam and seafaring wooden cases to ensure safe transport and delivery worldwide.

Product Advantages

- High strength and corrosion resistance.

- Space-saving, easy to install and clean.

- Durability and stability in various temperatures.

- Lightweight and eco-friendly material.

Product FAQ

- Q1: What materials are used in the extrusion profiles?

A1: We utilize high-quality PVC, ABS, and PE materials in our extrusion profiles, known for their robustness and durability, ideal for cooler applications. - Q2: Are the profiles customizable?

A2: Absolutely, Suppliers like YB offer customization in terms of shape, size, and color, catering to client-specific requirements. - Q3: How do these profiles enhance cooler performance?

A3: The profiles provide structural integrity, improved insulation, and customizable features that contribute to enhanced cooler efficiency and usability. - Q4: What are the color options available?

A4: We provide a range of color options including Silver, White, Brown, Black, Blue, and Green, among others, to match aesthetic preferences. - Q5: Are these profiles suitable for outdoor use?

A5: Yes, our profiles are crafted to withstand various environmental conditions, making them ideal for outdoor applications. - Q6: Can these profiles be used in residential buildings?

A6: Indeed, our profiles suit diverse applications from residential to commercial buildings, enhancing window and door utility. - Q7: What is the lead time for custom orders?

A7: Typically, custom orders are processed and delivered within a 4-6 week timeframe, depending on the complexity and quantity requested. - Q8: How do I ensure the longevity of these profiles?

A8: Regular maintenance, protection from extreme conditions, and proper installation will ensure these profiles last long and perform optimally. - Q9: Do these profiles require special installation tools?

A9: No special tools are required, standard installation tools suffice for setting up our extrusion profiles. - Q10: Are these profiles eco-friendly?

A10: Yes, our profiles are made from recyclable materials, adhering to eco-friendly manufacturing practices.

Product Hot Topics

- Topic 1: Durability of Plastic Extrusion Profile for Cooler

The durability of Plastic Extrusion Profiles for Cooler applications is a hot discussion topic among Suppliers, focusing on the material's ability to withstand environmental stress. These profiles are specifically engineered to endure temperature fluctuations, impacts, and UV exposure, ensuring long-term use. Suppliers are continually improving the material composition to enhance these properties, enabling coolers to maintain functionality and aesthetics over time, which in turn appeals to a wider consumer base.

- Topic 2: Customizability of Plastic Extrusion Profile for Cooler Designs

The customization potential of extrusion profiles is a significant advantage for Suppliers of Plastic Extrusion Profile for Cooler designs. The flexibility in design allows manufacturers to create tailored solutions that meet specific client needs, from unique shapes to a variety of color options. This adaptability not only helps in meeting specific aesthetic and functional requirements but also positions Suppliers as innovative leaders in the cooler component manufacturing industry.

- Topic 3: Cost-Efficiency in Mass Production of Cooler Profiles

Cost-efficiency remains a top consideration for Suppliers when producing Plastic Extrusion Profiles for Cooler applications. The extrusion process is inherently economical, facilitating large-scale production without compromising quality. This efficiency is especially crucial for meeting the demands of global distribution and competitive pricing. By optimizing production processes, Suppliers can deliver high-quality profiles at scale, maintaining profitability while meeting market demands.

- Topic 4: Advancements in Eco-Friendly Plastic Extrusion for Coolers

As environmental concerns rise, Suppliers are focusing on developing eco-friendly Plastic Extrusion Profiles for Cooler applications. Advances in recyclable and biodegradable materials signify a move toward sustainable manufacturing. Suppliers are committed to reducing their environmental impact by integrating these materials into their extrusion processes, thereby offering greener options to environmentally conscious consumers.

- Topic 5: Enhancing Insulation Efficiency with Extruded Profiles

Suppliers of Plastic Extrusion Profile for Cooler are concentrating efforts on enhancing insulation efficiency through precise profile engineering. The ability to create airtight seals and minimized heat transfer through specialized profiles frames the future of cooler innovations. These advancements not only improve energy efficiency but also extend the lifespan of cooler contents, appealing to both commercial and residential users seeking optimal insulation solutions.

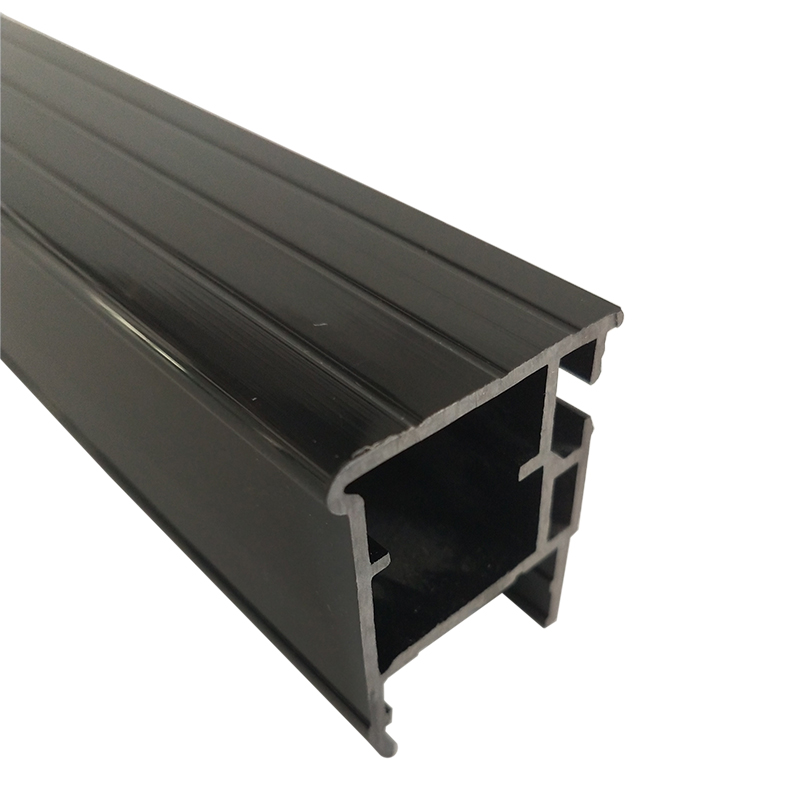

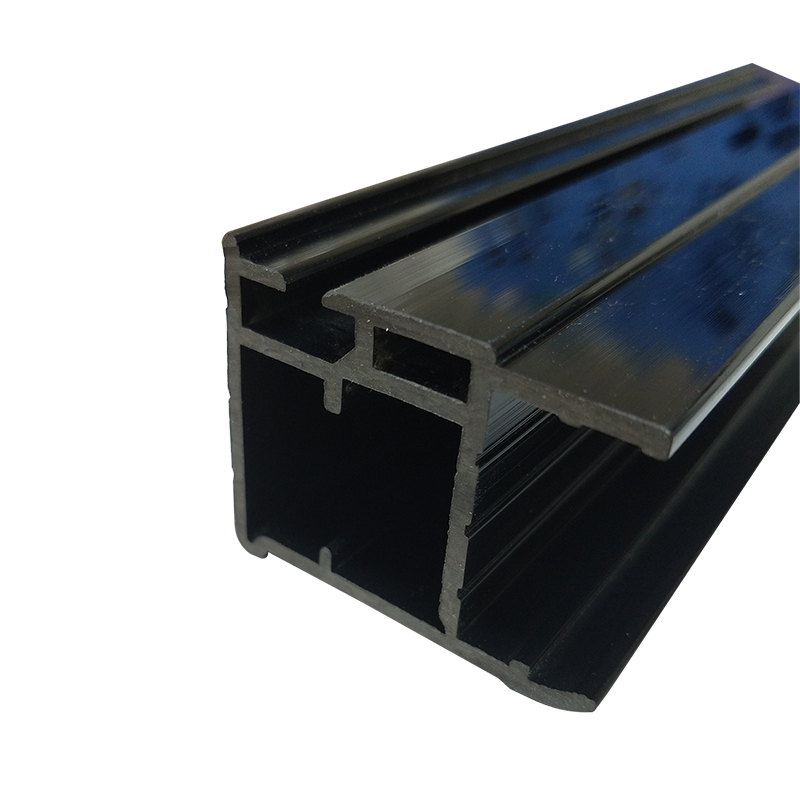

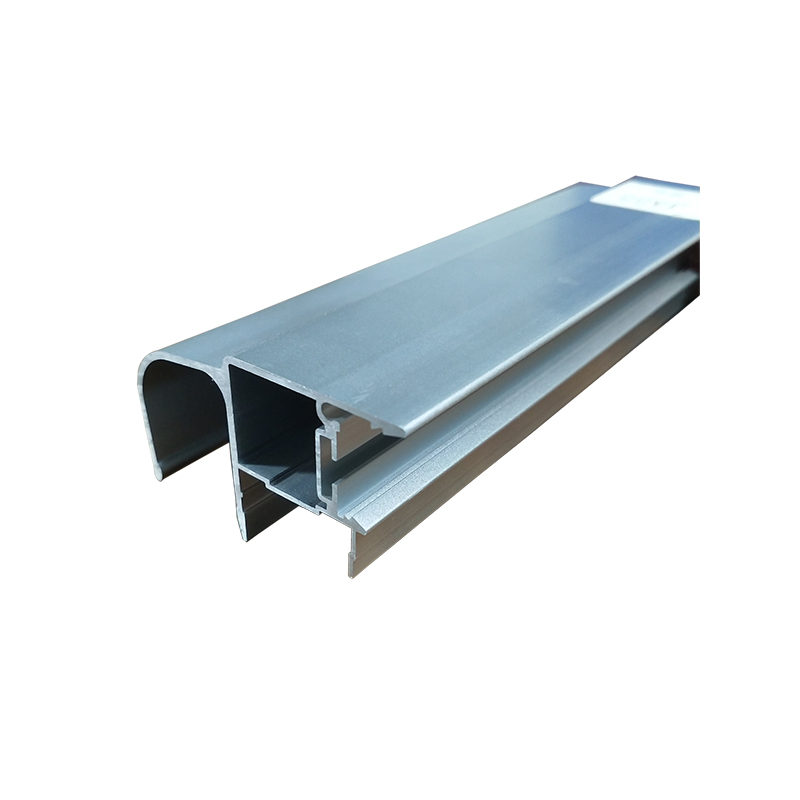

Image Description