Product Main Parameters

| Attribute | Value |

|---|---|

| Material | Polyvinyl Chloride (PVC) |

| Temperature Resistance | -40℃ to 80℃ |

| Color Options | Customizable |

| Application | Freezer Gaskets, Trims, Components |

Common Product Specifications

| Specification | Detail |

|---|---|

| Density | 1.4 g/cm³ |

| Hardness | 80 Shore D |

| Tensile Strength | 45 N/mm² |

| Impact Resistance | Notched Impact Strength 15 kj/m² |

Product Manufacturing Process

In the authoritative paper titled 'Advanced Materials in Engineering', the extrusion process of PVC involves the precise shaping of polymer materials through die channels under controlled temperatures and pressures. This process ensures consistent quality and capacity for intricate designs, meeting the appliance industry's stringent standards. PVC's adaptability to additives further optimizes it for various freezer applications, safeguarding against chemical corrosion and ensuring thermal performance, which are crucial for freezer efficiency.

Product Application Scenarios

According to the journal 'Polymer Science and Technology', PVC extrusion parts are pivotal in the appliance industry. Their use in freezers includes energy-efficient door gaskets, durable trims, and internal components that resist corrosion and maintain hygiene. These applications underscore the material's versatility and importance in delivering sustainable solutions in cold storage systems worldwide.

Product After-Sales Service

We offer comprehensive after-sales support including installation guidance, warranty services, and replacement options to ensure satisfaction and product longevity.

Product Transportation

Products are securely packaged and shipped via reliable logistics partners, ensuring timely and safe delivery to global destinations.

Product Advantages

- Durable and lightweight

- Customizable for various applications

- Eco-friendly options available

- Cost-effective manufacturing

- Superior thermal performance

Product FAQ

- What is the temperature range that PVC extrusion parts can withstand?

As suppliers, we provide pvc extrusion part for freezer that can reliably withstand temperatures from -40℃ to 80℃, ensuring performance under varying conditions.

- Are these parts customizable?

Yes, suppliers can provide pvc extrusion part for freezer in different colors and specifications based on customer demand, ensuring compatibility with unique designs.

- How does PVC contribute to energy efficiency in freezers?

PVC's low thermal conductivity helps maintain internal temperatures, reducing energy consumption—key for pvc extrusion part for freezer supplied to enhance appliance efficiency.

- What makes PVC suitable for freezer gaskets?

Suppliers choose PVC for its flexibility, durability, and resistance to moisture, making it ideal for seals that prevent cold air loss in freezers.

- What are the key benefits of using PVC in freezers?

Suppliers focus on PVC's robustness, lightweight nature, and cost-effectiveness, making it a preferred material for extrusion parts in freezer manufacturing.

- Is recycled PVC available?

Yes, suppliers increasingly offer recyclable pvc extrusion part for freezer, supporting environmental sustainability efforts without compromising on quality.

- Can PVC withstand impacts?

PVC extrusion parts for freezers are designed to be damage-resistant and maintain integrity, offering reliable protection for appliance edges and interiors.

- What are common applications of PVC extrusion parts?

Suppliers provide pvc extrusion part for freezer used in door gaskets, trims, internal supports, and protective components, serving essential roles in appliance functionality.

- How do suppliers ensure quality?

With strict quality control, suppliers ensure that each pvc extrusion part for freezer meets industry standards, using advanced testing techniques for durability and performance.

- What advancements are being made in PVC technology?

Suppliers are adopting new compounding techniques allowing for customized attributes such as enhanced UV resistance and increased impact strength for pvc extrusion part for freezer applications.

Product Hot Topics

- The Future of PVC Extrusion in Freezer Manufacturing

The sustained innovation in materials and processes is keeping suppliers of pvc extrusion part for freezer at the forefront of efficiency and eco-friendliness. As the appliance industry strives to meet environmental standards, suppliers are exploring bio-based PVC and advanced recycling techniques to offer more sustainable solutions.

- How PVC Extrusion Revolutionizes Freezer Efficiency

Suppliers are pivotal in improving freezer efficiency by developing pvc extrusion part for freezer that ensure superior insulation and reduce energy waste. Innovations in material science are enabling more effective thermal barriers, highlighting the role of PVC in meeting energy standards.

- Customization: The Key Advantage for PVC Extrusion Suppliers

Supplying pvc extrusion part for freezer with customization options allows manufacturers to design flexible solutions that cater to specific aesthetic and functional requirements. This capability ensures that PVC remains a versatile choice in an evolving market.

- The Environmental Impact of PVC in Appliance Production

PVC supplies, especially in extrusion parts for freezers, are increasingly incorporating recycled and eco-friendly materials. Suppliers are committed to reducing carbon footprints and contributing to a more sustainable industry through innovative material use.

- PVC Extrusion: Addressing Global Freezer Demands

As global demand for efficient refrigeration solutions grows, suppliers of pvc extrusion part for freezer are scaling production capabilities. Emphasis is placed on maintaining quality while meeting the diverse needs of international markets, reflecting PVC's adaptability.

- Technological Advancements in PVC Extrusion Processes

Suppliers continue to refine extrusion technologies to enhance the precision and efficiency of pvc extrusion part for freezer production. Incorporating next-gen die designs and automation improves output quality and reduces lead times.

- Why Choose PVC Over Other Materials?

PVC's unique attributes, such as chemical resistance and low thermal conductivity, make it indispensable for freezers. Suppliers favor pvc extrusion part for freezer over alternatives, ensuring enhanced performance and cost savings for manufacturers.

- The Role of Suppliers in PVC Innovation

Suppliers stand at the helm of pvc extrusion part for freezer advancements, collaborating with research institutions to push the boundaries of material capabilities, driving the industry's progress toward enhanced performance and environmental goals.

- Challenges in PVC Extrusion for Freezers

While PVC remains a dominant material, suppliers face challenges such as maintaining consistency in diverse conditions and innovating around environmental regulations. The commitment to overcoming these ensures the material's continued relevance.

- Exploring New Markets with PVC Extrusion Parts

Suppliers of pvc extrusion part for freezer are tapping into emerging markets by offering tailored solutions that address local needs for energy efficiency and durability, thereby expanding global reach and influence in the appliance sector.

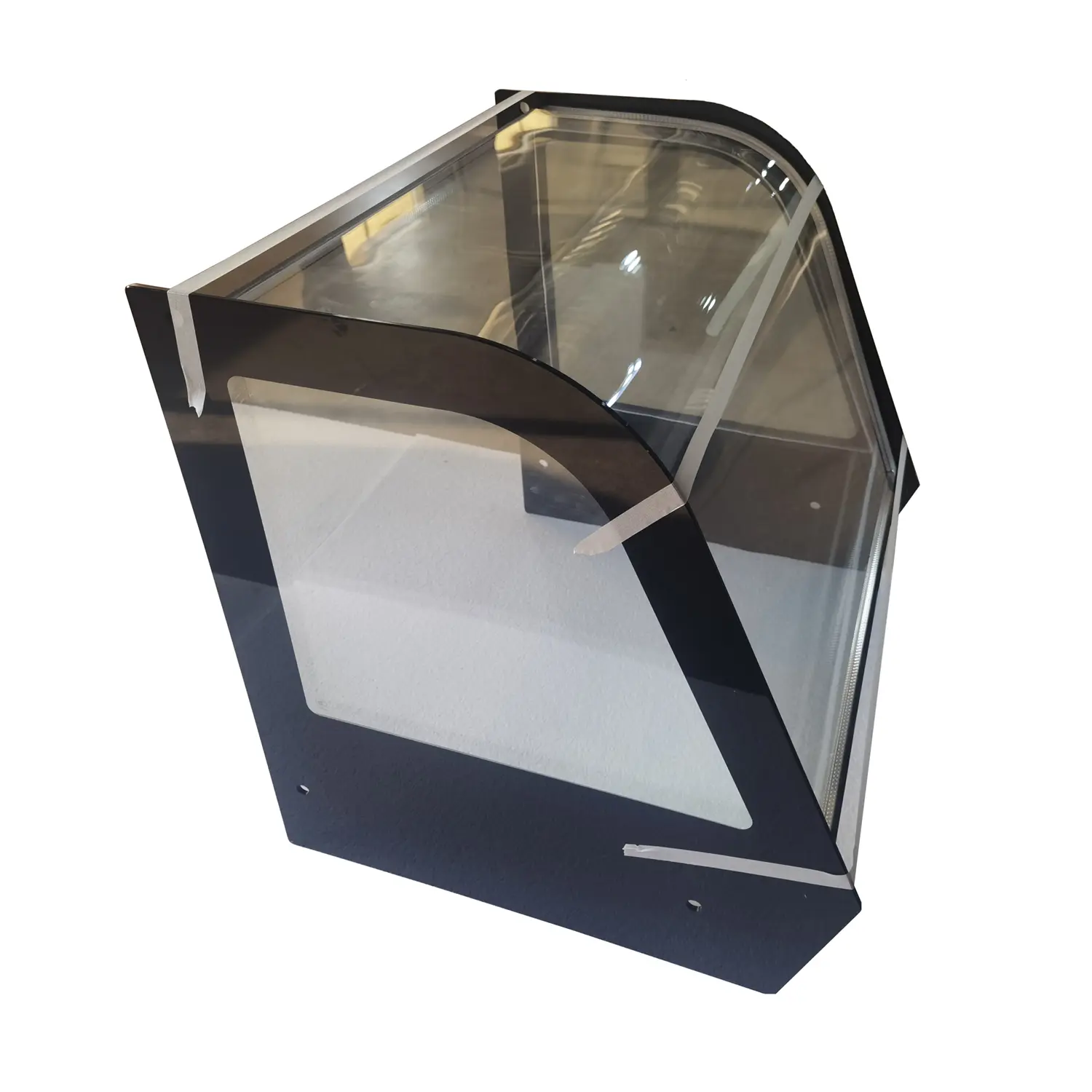

Image Description

There is no picture description for this product