Product Main Parameters

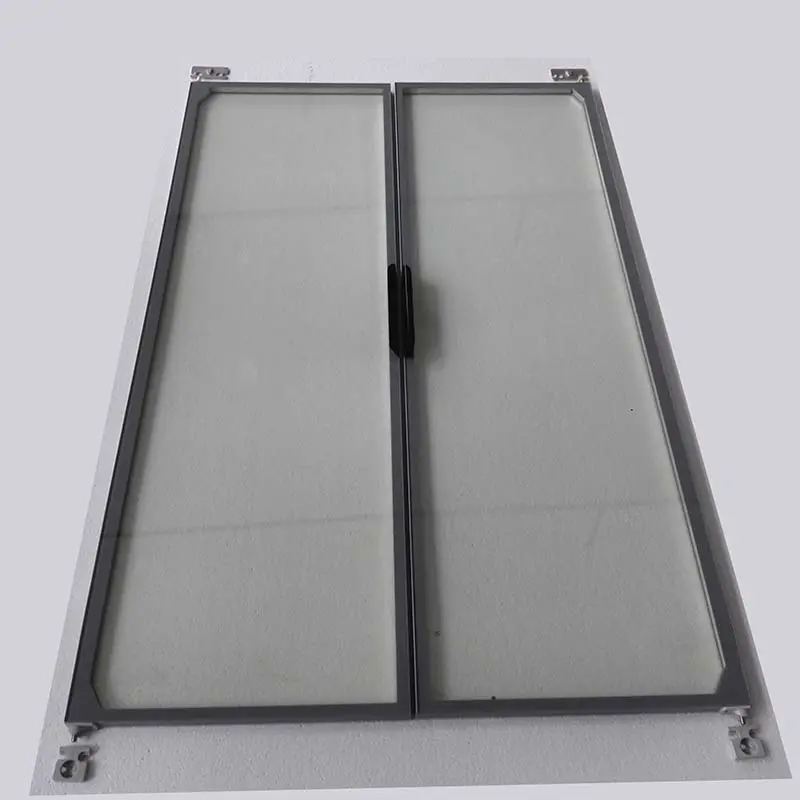

| Style | Up-open |

|---|---|

| Glass | Tempered, Low-E glass with silk print edge |

| Glass Thickness | 4mm |

| Frame | Aluminum Alloy |

| Color | Silver |

| Temperature Range | -18℃ to 30℃ |

| Door Qty. | 1pcs or 2 pcs swing glass door |

| Application | Deep Freezer, Horizontal Freezer, Display Cabinets |

| Usage Scenario | Supermarket, Chain Store, Meat Shop, Fruit Store, Restaurant |

Common Product Specifications

| Warranty | 1 Year |

|---|---|

| Service | OEM, ODM |

| After-sales Service | Free Spare Parts |

Product Manufacturing Process

The production of Vacuum Insulated Glass Doors for freezers involves several precise steps that ensure durability and efficiency. The process begins with glass cutting, followed by meticulous edge polishing to remove sharp edges. Holes are then drilled and notched for hinge insertion. The glass is cleaned to remove impurities before undergoing silk printing. It is then tempered for increased strength and assembled with a vacuum layer for insulation. The assembly includes the aluminum alloy frame with a PVC extrusion profile for enhanced sealing. Studies highlight the importance of precise vacuum sealing to ensure minimal heat transfer, thereby increasing energy efficiency.

Product Application Scenarios

Vacuum Insulated Glass Doors for freezers are widely used in various commercial settings due to their superior energy efficiency and durability. They are prevalent in supermarkets and chain stores, where maintaining product visibility and temperature is crucial. Meat shops and fruit stores favor these doors to enhance the customer experience by preventing condensation and maintaining product freshness. Restaurants utilize these glass doors in display cabinets to optimize energy usage while showcasing products effectively. Recent studies emphasize that reducing energy consumption through advanced insulation technologies contributes significantly to environmental sustainability.

Product After-Sales Service

We offer comprehensive after-sales service, including free spare parts during the warranty period. Our dedicated support team ensures that any product issues are resolved promptly, maintaining your freezer's performance and efficiency.

Product Transportation

Products are shipped with EPE foam packaging and seaworthy wooden cases to ensure maximum protection during transit. We work with reliable logistics providers to guarantee timely and safe delivery.

Product Advantages

- Energy Efficiency: Cutting-edge insulation technology reduces energy consumption, lowering operational costs.

- Durability: Tempered glass and robust aluminum frames ensure long-lasting performance.

- Visibility: Anti-fog properties maintain clear visibility of products.

- Environmental Impact: Reduced energy usage contributes to sustainability efforts.

Product FAQ

What are the advantages of Vacuum Insulated Glass Door over traditional doors?

Suppliers highlight superior insulation, lower energy costs, and improved product visibility as key advantages of Vacuum Insulated Glass Doors for freezers.

Can the Vacuum Insulated Glass Door be customized?

Yes, our Suppliers offer customization options for size, frame color, and design to meet specific freezer requirements.

How do Vacuum Insulated Glass Doors improve energy efficiency?

The vacuum layer reduces heat transfer, decreasing the workload on cooling systems and energy consumption, making them superior alternatives supplied by leading manufacturers.

What maintenance is required for these doors?

Suppliers suggest regular cleaning and occasional checks on seals to ensure optimal performance of Vacuum Insulated Glass Doors for freezers.

Are these doors available for both commercial and residential use?

While primarily designed for commercial settings, Suppliers offer models suitable for residential use, maximizing energy efficiency across applications.

How long is the warranty for these doors?

Our Suppliers provide a one-year warranty covering parts and service for Vacuum Insulated Glass Doors for freezers.

What packaging is used for shipping the doors?

Suppliers ensure safe delivery using EPE foam and seaworthy wooden case packaging for Vacuum Insulated Glass Doors for freezers.

Can the doors be integrated with existing freezer systems?

Yes, our Suppliers provide models compatible with various freezer systems, facilitating seamless integration.

What color options are available for the frame?

Commonly, silver aluminum alloy frames are available, but Suppliers offer customization on request for Vacuum Insulated Glass Doors for freezers.

Do these doors prevent condensation?

Yes, the Suppliers’ Vacuum Insulated Glass Doors are designed to minimize condensation, ensuring product visibility and customer satisfaction.

Product Hot Topics

How Does Vacuum Technology Revolutionize Freezer Efficiency?

Suppliers are at the forefront of this revolution, offering Vacuum Insulated Glass Doors that transform freezer efficiency. The integration of vacuum technology reduces thermal conductivity, ensuring lower energy consumption. Vendors emphasize that this not only cuts operational costs but also aligns with green initiatives by reducing the carbon footprint. As companies prioritize sustainability, the market for such advanced refrigeration solutions is expected to grow substantially.

The Future of Retail: Will Glass Doors Replace Traditional Freezer Doors?

With Suppliers introducing innovative Vacuum Insulated Glass Doors for freezers, the retail landscape is poised for a shift. These doors offer enhanced product visibility and energy savings, prompting retailers to adopt this technology. Discussions among industry leaders suggest that as the advantages become more apparent, traditional door systems may gradually be phased out in favor of more efficient glass solutions.

What Are the Environmental Impacts of Transitioning to Vacuum Insulated Glass Doors?

Suppliers highlight significant environmental benefits associated with Vacuum Insulated Glass Doors for freezers. By reducing energy usage, these doors contribute to lower greenhouse gas emissions. As regulatory pressures and consumer demand for sustainable practices increase, adopting such energy-efficient solutions could play a critical role in environmentally responsible retail operations.

Why Are More Supermarkets Opting for Vacuum Insulated Glass Technology?

Suppliers of Vacuum Insulated Glass Doors report a growing trend among supermarkets to opt for this advanced technology. The enhanced energy efficiency, combined with clear visibility and reduced maintenance needs, results in substantial cost savings. Retailers recognize the competitive advantage of presenting fresh, visible products while reducing energy bills.

Challenges in Manufacturing Vacuum Insulated Glass Doors

The production of Vacuum Insulated Glass Doors for freezers poses challenges, notably ensuring a perfect vacuum seal. Suppliers need to maintain stringent quality controls and invest in advanced machinery to overcome these hurdles. The payoff, however, is a superior product that meets current demands for energy efficiency and durability.

Is Customization the Key Advantage in Today's Freezer Door Market?

Suppliers who offer customization options for Vacuum Insulated Glass Doors stand out in the competitive market. Tailoring products to fit specific needs allows businesses to optimize space, energy use, and aesthetics, resulting in a bespoke solution that aligns with their branding and operational requirements.

The Role of Suppliers in Advancing Freezer Door Technology

Suppliers play a vital role in advancing freezer door technology by researching and implementing new materials and manufacturing methods that enhance product performance. Their initiative towards Vacuum Insulated Glass Doors exemplifies leadership in innovation, ensuring that industry standards continue to evolve.

Comparative Cost Analysis: Traditional vs. Vacuum Insulated Glass Doors

Cost analysis by Suppliers indicates that while Vacuum Insulated Glass Doors for freezers may have a higher initial investment, the long-term savings in energy costs make them economically viable. Retailers are encouraged to consider the lifecycle cost benefits when choosing between traditional and advanced door systems.

How Do Vacuum Insulated Glass Doors Impact Product Presentation?

Suppliers assert that Vacuum Insulated Glass Doors for freezers significantly improve product presentation. The anti-fog technology ensures clear visibility, enhancing the consumer shopping experience. Retailers using these doors have reported increased sales, underscoring the importance of clear and appealing product displays.

Exploring the Durability of Vacuum Insulated Glass Doors

Durability is a key focus for Suppliers of Vacuum Insulated Glass Doors for freezers. The use of tempered glass and robust frames ensures a product that withstands the rigors of daily use. Maintenance and replacement costs are reduced, making these doors a long-term investment in reliable refrigeration solutions.

Image Description

There is no picture description for this product